A commutator is a crucial component in electric motors and generators that ensures the correct direction of current flow, enabling efficient energy conversion. It consists of segmented copper bars and brushes that maintain electrical contact while the motor or generator rotates. Explore the rest of this article to understand how a commutator impacts your device's performance and maintenance.

Table of Comparison

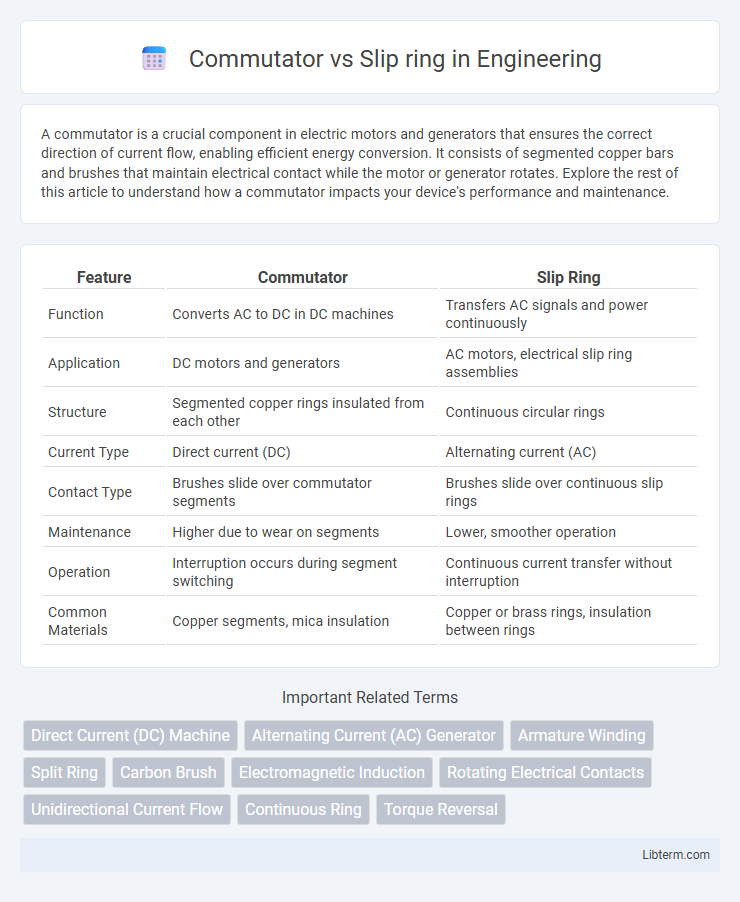

| Feature | Commutator | Slip Ring |

|---|---|---|

| Function | Converts AC to DC in DC machines | Transfers AC signals and power continuously |

| Application | DC motors and generators | AC motors, electrical slip ring assemblies |

| Structure | Segmented copper rings insulated from each other | Continuous circular rings |

| Current Type | Direct current (DC) | Alternating current (AC) |

| Contact Type | Brushes slide over commutator segments | Brushes slide over continuous slip rings |

| Maintenance | Higher due to wear on segments | Lower, smoother operation |

| Operation | Interruption occurs during segment switching | Continuous current transfer without interruption |

| Common Materials | Copper segments, mica insulation | Copper or brass rings, insulation between rings |

Introduction to Commutators and Slip Rings

Commutators and slip rings are crucial components in electric machines, enabling the transfer of electrical current between stationary and rotating parts. A commutator is segmented and used in DC machines to reverse current direction, ensuring unidirectional torque. In contrast, slip rings are continuous rings employed in AC machines or for transmitting power to rotating equipment without altering current direction.

Definition and Basic Function

A commutator is a rotary electrical switch in direct current (DC) machines that reverses the direction of current flow in the armature windings to ensure unidirectional torque. A slip ring is a continuous rotating electrical connector used in alternating current (AC) machines to transfer power and signals without changing current direction. The commutator enables DC machines to produce steady torque, while slip rings allow for continuous rotation and signal transmission in AC systems.

Structural Differences

A commutator consists of segmented copper bars insulated from each other and mounted on a rotating shaft, enabling the conversion of alternating current induced in the armature windings into direct current by reversing the current direction. A slip ring is a continuous conductive ring mounted on a rotating shaft that maintains an unbroken electrical connection, allowing the transmission of alternating current or signals without changing their direction. The primary structural difference lies in the segmented design of the commutator versus the continuous, circular design of the slip ring, influencing their respective applications in DC and AC machines.

How Commutators Work

Commutators work by reversing the current direction in the armature windings of a DC motor or generator, ensuring that the torque generated remains unidirectional and consistent. They consist of segmented copper rings connected to the armature coils and are contacted by stationary carbon brushes, which transfer electrical current while maintaining rotation. This mechanical switching action enables continuous rotation and efficient energy conversion, differentiating commutators from slip rings that transmit AC signals without reversing current.

How Slip Rings Work

Slip rings function by providing a continuous electrical connection between stationary and rotating parts, allowing the transmission of power and signals without tangling wires. They consist of a stationary brush that maintains contact with a rotating ring, enabling 360-degree rotation while ensuring uninterrupted conductivity. Commonly used in applications like wind turbines and electric motors, slip rings facilitate smooth rotational movement and reliable electrical transfer.

Key Applications of Commutators

Commutators are primarily used in DC motors and generators to reverse current direction, enabling efficient conversion of electrical energy to mechanical energy and vice versa. They are essential in applications such as electric trains, power tools, and household appliances where controlled, unidirectional current flow is critical. Slip rings, by contrast, maintain continuous connection for AC signals or power without reversing current, making commutators ideal for devices requiring directional current switching.

Key Applications of Slip Rings

Slip rings are essential components in systems requiring continuous rotation with electrical signal or power transfer, commonly found in wind turbines, radar antennas, and medical imaging devices. Their key applications also include robotics, electric generators, and rotating sensors where smooth and uninterrupted electrical connectivity is critical. Unlike commutators that convert AC to DC, slip rings efficiently transmit power and signals in AC or DC systems without the need for mechanical switching.

Advantages and Disadvantages

Commutators provide unidirectional current in DC machines, ensuring consistent torque but suffer from wear due to brush friction and maintenance requirements. Slip rings enable continuous AC signal transmission and smooth rotational motion with less contact wear but cannot rectify current, limiting their use in DC applications. Choosing between commutators and slip rings depends on the need for current type, durability, and maintenance overhead.

Common Issues and Maintenance

Commutators often face issues such as sparking, wear of brushes, and uneven surface caused by electrical arcing, requiring regular inspection and resurfacing to maintain optimal conductivity. Slip rings experience common problems like corrosion, contamination, and brush wear, demanding consistent cleaning and lubrication to prevent signal loss and mechanical failure. Proper maintenance routines, including timely replacement of brushes and monitoring for electrical noise, extend the operational life of both commutators and slip rings in rotating electrical machines.

Choosing Between Commutator and Slip Ring

Choosing between a commutator and a slip ring depends on the type of current and application requirements; commutators are essential for converting AC to DC in DC motors, ensuring unidirectional torque, while slip rings maintain continuous AC transmission in generators and synchronous motors without signal interruption. Slip rings provide smooth rotary electrical connections for AC circuits and sensors in rotating equipment, offering reliability and minimal maintenance. Selecting the right component depends on whether the device requires current rectification or uninterrupted AC power flow during rotation.

Commutator Infographic

libterm.com

libterm.com