Fused Deposition Modeling (FDM) is a popular 3D printing technique that builds objects by extruding thermoplastic filaments layer by layer. This method offers cost-effective production, rapid prototyping, and the ability to create complex geometries with excellent mechanical properties. Explore the rest of the article to discover how FDM can enhance your manufacturing or design projects.

Table of Comparison

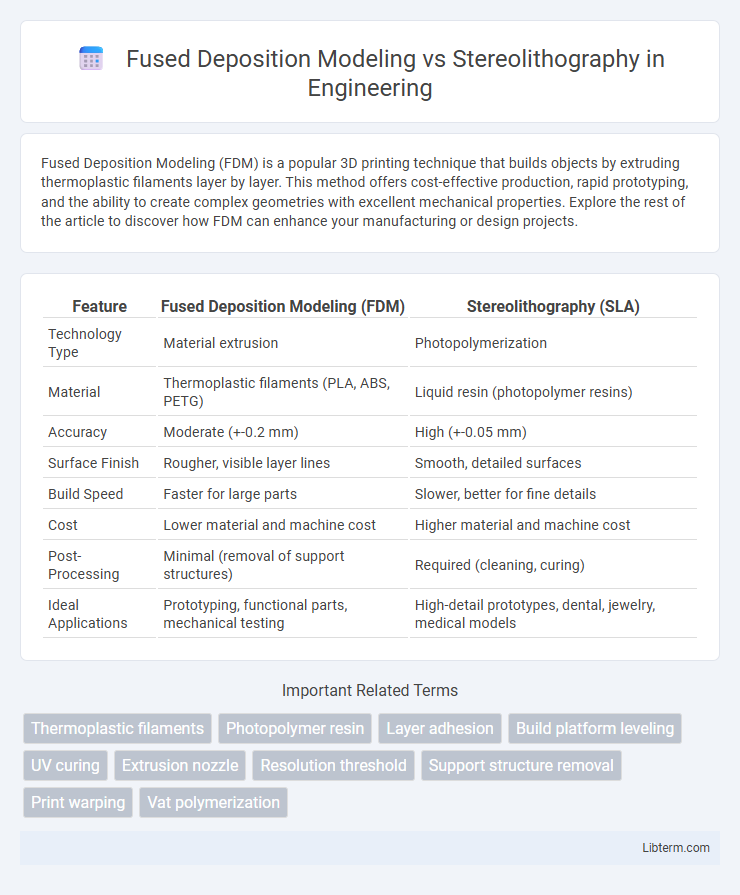

| Feature | Fused Deposition Modeling (FDM) | Stereolithography (SLA) |

|---|---|---|

| Technology Type | Material extrusion | Photopolymerization |

| Material | Thermoplastic filaments (PLA, ABS, PETG) | Liquid resin (photopolymer resins) |

| Accuracy | Moderate (+-0.2 mm) | High (+-0.05 mm) |

| Surface Finish | Rougher, visible layer lines | Smooth, detailed surfaces |

| Build Speed | Faster for large parts | Slower, better for fine details |

| Cost | Lower material and machine cost | Higher material and machine cost |

| Post-Processing | Minimal (removal of support structures) | Required (cleaning, curing) |

| Ideal Applications | Prototyping, functional parts, mechanical testing | High-detail prototypes, dental, jewelry, medical models |

Introduction to Fused Deposition Modeling (FDM) and Stereolithography (SLA)

Fused Deposition Modeling (FDM) is an additive manufacturing process that builds objects by extruding thermoplastic filament layer by layer, commonly used for prototyping due to its affordability and wide material compatibility. Stereolithography (SLA) utilizes a UV laser to cure liquid photopolymer resin into solid structures with high precision and smooth surface finish, ideal for detailed and complex designs. Both FDM and SLA serve distinct applications, where FDM excels in functional prototypes and larger parts, while SLA is preferred for accuracy and fine details in jewelry, dental, and engineering models.

How Fused Deposition Modeling Works

Fused Deposition Modeling (FDM) works by extruding thermoplastic filament through a heated nozzle, layer by layer, to build a three-dimensional object based on a digital 3D model. The nozzle moves along the X and Y axes to deposit molten material precisely, while the build platform shifts along the Z-axis to create successive layers. Compared to Stereolithography (SLA), which uses a laser to cure liquid resin, FDM is valued for its affordability, accessibility, and ability to print with a variety of durable plastic materials.

How Stereolithography Works

Stereolithography (SLA) operates by using a UV laser to selectively cure liquid photopolymer resin layer by layer, solidifying each cross-section of the digital 3D model. This process achieves high resolution and smooth surface finishes by precisely controlling the laser beam to trace the part's geometry on the resin vat's surface. SLA is ideal for producing detailed prototypes and complex geometries with superior accuracy compared to Fused Deposition Modeling (FDM), which extrudes thermoplastic filament through a heated nozzle.

Material Compatibility: FDM vs SLA

Fused Deposition Modeling (FDM) primarily uses thermoplastic filaments such as PLA, ABS, and PETG, offering broad compatibility with durable, impact-resistant materials suitable for functional prototyping and end-use parts. Stereolithography (SLA) employs photopolymer resins that provide superior resolution and surface finish, but material options are often more specialized, including standard, flexible, castable, and biocompatible resins. Material compatibility in FDM favors mechanical strength and versatility, while SLA excels in precision and detail with resin formulations tailored to specific application needs.

Print Quality and Surface Finish Comparison

Fused Deposition Modeling (FDM) typically produces parts with visible layer lines and a rougher surface finish due to the extrusion of thermoplastic filaments, resulting in lower resolution and less detailed prints. Stereolithography (SLA) utilizes a laser to cure liquid resin layer by layer, delivering high-resolution prints with smooth surface finishes and fine detail accuracy ideal for prototypes and intricate designs. The superior print quality and surface finish of SLA make it preferable for applications demanding precise geometrical features and minimal post-processing.

Speed and Efficiency Differences

Fused Deposition Modeling (FDM) typically offers faster print times for larger, less detailed parts due to its layer-by-layer extrusion process and simpler setup requirements. Stereolithography (SLA) excels in producing highly detailed and smooth surface finishes but generally operates slower, as it relies on curing resin layer by layer with a laser or projector. Efficiency in FDM is enhanced by lower material costs and easier maintenance, whereas SLA demands more post-processing and resin handling, impacting overall throughput.

Cost Analysis: FDM vs SLA

Fused Deposition Modeling (FDM) generally offers lower initial equipment and material costs compared to Stereolithography (SLA), making it more accessible for budget-conscious users. SLA printers and their photopolymer resins tend to be more expensive due to high-resolution capabilities and intricate post-processing requirements. While FDM is cost-effective for rapid prototyping and large-scale production, SLA is favored for detailed, high-precision parts despite higher operational expenses.

Applications and Industry Uses

Fused Deposition Modeling (FDM) excels in rapid prototyping and functional parts fabrication, commonly used in automotive, aerospace, and consumer goods industries due to its cost-effectiveness and material versatility. Stereolithography (SLA) offers superior surface finish and high resolution, making it ideal for dental, jewelry, and medical device applications where precision and detail are critical. Both technologies serve complementary roles in product development, balancing speed, accuracy, and material properties to meet diverse industrial requirements.

Maintenance and Post-Processing Requirements

Fused Deposition Modeling (FDM) requires regular maintenance of the nozzle and extruder to prevent clogs and ensure consistent filament flow, while post-processing typically involves sanding and smoothing layer lines. Stereolithography (SLA) demands routine cleaning of resin tanks and careful handling of liquid resin, with post-processing steps including washing prints in isopropyl alcohol and UV curing to achieve optimal surface finish. Both technologies require specific maintenance and post-processing actions that directly impact print quality and machine longevity.

Choosing the Right 3D Printing Technology

Fused Deposition Modeling (FDM) excels in affordability and material versatility, making it ideal for functional prototypes and larger parts requiring durable thermoplastics. Stereolithography (SLA) offers superior surface finish and high-resolution details, perfect for intricate designs, jewelry, and dental models needing precision and smoothness. Selecting between FDM and SLA depends on project requirements, balancing cost, detail, material properties, and end-use application.

Fused Deposition Modeling Infographic

libterm.com

libterm.com