PLCs (Programmable Logic Controllers) and microcontrollers serve distinct roles in automation and control systems, with PLCs being ideal for industrial environments due to their robustness and ability to handle complex input/output operations. Microcontrollers are better suited for embedded applications requiring compact size and efficient processing power. Explore this article to discover how your choice between PLCs and microcontrollers can optimize your project's performance and reliability.

Table of Comparison

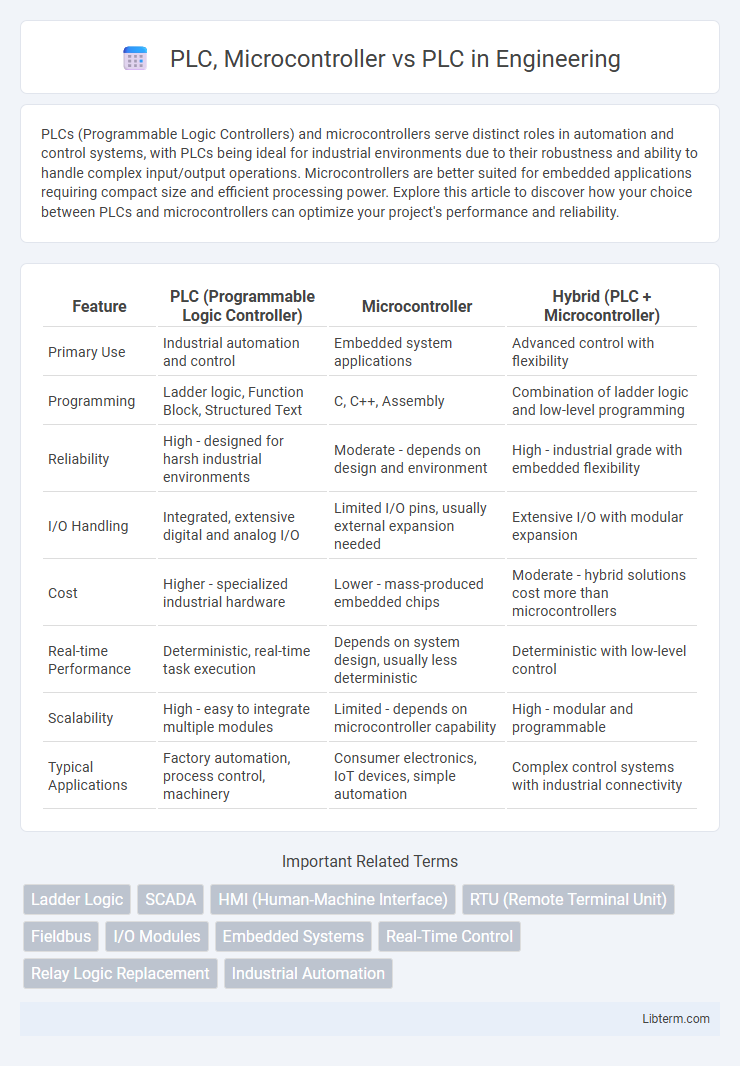

| Feature | PLC (Programmable Logic Controller) | Microcontroller | Hybrid (PLC + Microcontroller) |

|---|---|---|---|

| Primary Use | Industrial automation and control | Embedded system applications | Advanced control with flexibility |

| Programming | Ladder logic, Function Block, Structured Text | C, C++, Assembly | Combination of ladder logic and low-level programming |

| Reliability | High - designed for harsh industrial environments | Moderate - depends on design and environment | High - industrial grade with embedded flexibility |

| I/O Handling | Integrated, extensive digital and analog I/O | Limited I/O pins, usually external expansion needed | Extensive I/O with modular expansion |

| Cost | Higher - specialized industrial hardware | Lower - mass-produced embedded chips | Moderate - hybrid solutions cost more than microcontrollers |

| Real-time Performance | Deterministic, real-time task execution | Depends on system design, usually less deterministic | Deterministic with low-level control |

| Scalability | High - easy to integrate multiple modules | Limited - depends on microcontroller capability | High - modular and programmable |

| Typical Applications | Factory automation, process control, machinery | Consumer electronics, IoT devices, simple automation | Complex control systems with industrial connectivity |

Introduction to PLCs and Microcontrollers

Programmable Logic Controllers (PLCs) are industrial digital computers designed for automation of electromechanical processes, featuring robust hardware for real-time control and programmable input/output modules. Microcontrollers are compact integrated circuits containing a processor core, memory, and programmable peripherals, optimized for embedded systems with lower complexity and cost. PLCs excel in harsh industrial environments with modularity and scalability, while microcontrollers suit simple, cost-sensitive applications requiring precise control.

What is a PLC?

A Programmable Logic Controller (PLC) is an industrial digital computer designed for automation of electromechanical processes, such as control of machinery on factory assembly lines. Unlike microcontrollers, which integrate CPU, memory, and peripherals on a single chip for embedded applications, PLCs are ruggedized for harsh environments and provide extensive I/O capabilities, real-time processing, and reliable operation in complex control systems. PLCs support ladder logic programming and are optimized for scalability, ease of maintenance, and integration with industrial networks and sensors.

What is a Microcontroller?

A microcontroller is a compact integrated circuit designed to govern specific operations in embedded systems, combining a processor, memory, and input/output peripherals on a single chip. Unlike a PLC (Programmable Logic Controller), which is tailored for complex industrial automation with robust interfaces and real-time control capabilities, microcontrollers excel in cost-effective, low-power applications such as consumer electronics and simple control systems. Microcontrollers provide flexible programming options and are ideal for tasks requiring precise timing and control within compact hardware environments.

Core Functions of PLCs

PLCs (Programmable Logic Controllers) specialize in industrial automation, offering robust real-time control, durability, and seamless integration with sensors and actuators for precise process management. Unlike microcontrollers, which serve general-purpose embedded applications, PLCs emphasize core functions such as ladder logic programming, deterministic operation, and extensive I/O handling for complex control tasks in manufacturing environments. Key features of PLCs include high reliability, modular architecture, and fault tolerance, ensuring continuous operation in harsh industrial settings.

Core Functions of Microcontrollers

Microcontrollers integrate a CPU, memory, and input/output peripherals on a single chip, enabling control of embedded systems with low power consumption and real-time processing capabilities. Unlike PLCs, which are designed for industrial automation with rugged hardware and extensive input/output handling, microcontrollers excel in precise core functions such as signal processing, sensor interfacing, and executing control algorithms in compact applications. Their versatility supports a wide range of tasks including motor control, data acquisition, and communication protocols, making them ideal for customized automation solutions.

Key Differences: PLC vs Microcontroller

PLCs (Programmable Logic Controllers) are industrial-grade devices designed for real-time automation control in harsh environments, featuring robust hardware with extensive input/output (I/O) options and standardized programming languages like Ladder Logic. Microcontrollers, embedded within smaller systems, offer low-cost, flexible control with integrated peripherals but lack the ruggedness and specialized interfaces of PLCs, making them suitable for simpler, non-industrial applications. Key differences include PLCs' high reliability, scalability, and ease of networking in industrial systems, contrasted with microcontrollers' constrained processing power and memory optimized for embedded tasks rather than complex automation.

Advantages of Using PLCs

PLCs offer robust industrial automation capabilities with high reliability in harsh environments and easy integration into complex control systems, outperforming microcontrollers in scalability and real-time processing. Their modular design allows straightforward expansion and maintenance, reducing downtime and increasing operational efficiency in manufacturing processes. PLCs support extensive communication protocols and diagnostics, ensuring seamless connectivity and improved system monitoring for optimized production workflows.

Advantages of Using Microcontrollers

Microcontrollers offer greater flexibility and cost-effectiveness for embedded control applications compared to PLCs, making them ideal for custom and smaller-scale projects. They provide extensive programmability and integration options, including analog and digital interfaces, which enable precise control and efficient system design. Microcontrollers excel in low-power consumption and compact size, allowing deployment in space-constrained environments where PLCs may be impractical.

Typical Applications: PLC vs Microcontroller

PLCs are primarily used in industrial automation for tasks such as controlling assembly lines, robotic devices, and process automation due to their robustness and ease of integration with industrial equipment. Microcontrollers find typical applications in embedded systems like consumer electronics, automotive controls, and small-scale automation where cost-effectiveness and compact design are critical. The choice between PLC and microcontroller depends on the complexity, environment, and scalability of the application.

Choosing Between PLC and Microcontroller: Which is Right for Your Project?

Choosing between a PLC and a microcontroller depends on your project's complexity, environment, and scalability requirements. PLCs excel in industrial automation with robust, real-time control, easy programming, and high reliability under harsh conditions, while microcontrollers offer flexibility, cost efficiency, and customization for embedded systems and simpler control tasks. Evaluate factors like input/output needs, programming skill level, integration capabilities, and long-term maintenance to determine the best fit for industrial or embedded control applications.

PLC, Microcontroller Infographic

libterm.com

libterm.com