Cycle time measures the total duration needed to complete one entire process or production cycle, directly impacting operational efficiency and throughput. Reducing cycle time can enhance productivity, lower costs, and improve customer satisfaction by accelerating delivery. Explore the rest of the article to discover strategies for optimizing your cycle time and maximizing performance.

Table of Comparison

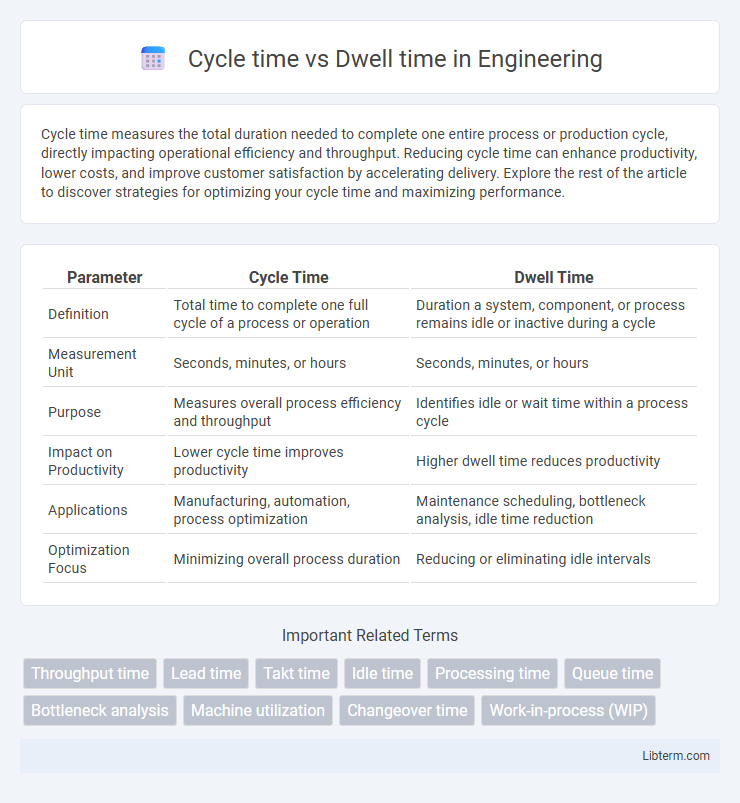

| Parameter | Cycle Time | Dwell Time |

|---|---|---|

| Definition | Total time to complete one full cycle of a process or operation | Duration a system, component, or process remains idle or inactive during a cycle |

| Measurement Unit | Seconds, minutes, or hours | Seconds, minutes, or hours |

| Purpose | Measures overall process efficiency and throughput | Identifies idle or wait time within a process cycle |

| Impact on Productivity | Lower cycle time improves productivity | Higher dwell time reduces productivity |

| Applications | Manufacturing, automation, process optimization | Maintenance scheduling, bottleneck analysis, idle time reduction |

| Optimization Focus | Minimizing overall process duration | Reducing or eliminating idle intervals |

Understanding Cycle Time: Definition and Importance

Cycle time measures the total duration required to complete one entire process or production cycle, from start to finish. It is crucial for optimizing operational efficiency, identifying bottlenecks, and improving throughput in manufacturing and service environments. Monitoring cycle time helps businesses reduce delays, enhance resource allocation, and increase overall productivity.

What is Dwell Time? Key Concepts Explained

Dwell time refers to the period a product or item remains stationary within a process or system before moving to the next stage, typically measured in manufacturing, logistics, or web analytics. It differs from cycle time, which encompasses the total duration to complete an entire process from start to finish. Understanding dwell time helps identify bottlenecks and inefficiencies by pinpointing delays or waiting periods within production lines or customer engagement metrics.

Cycle Time vs Dwell Time: Core Differences

Cycle time measures the total duration to complete a full process or production cycle, while dwell time refers to the period a product or component remains stationary or idle within a system. Cycle time encompasses all active and inactive phases affecting throughput, whereas dwell time specifically highlights delay or waiting intervals that do not add value. Understanding core differences between cycle time and dwell time is essential for improving operational efficiency and reducing bottlenecks in manufacturing or service workflows.

Why Measuring Cycle Time Matters in Operations

Measuring cycle time is crucial in operations as it directly impacts production efficiency and throughput, enabling accurate identification of bottlenecks and areas for improvement. Unlike dwell time, which captures idle or waiting periods, cycle time encompasses the total duration to complete a process from start to finish, providing a comprehensive metric for workflow optimization. Accurate cycle time measurement facilitates better resource allocation, reduces lead times, and enhances overall operational performance.

The Role of Dwell Time in Process Optimization

Dwell time plays a critical role in process optimization by representing the duration a component or workpiece remains stationary within a specific stage of production, directly affecting throughput and efficiency. Unlike cycle time, which measures the total time to complete one full process cycle, dwell time highlights bottlenecks where delays occur, enabling targeted improvements. Reducing dwell time through automation or streamlined workflows enhances overall process speed and minimizes idle periods, ultimately driving productivity gains.

Factors Influencing Cycle Time and Dwell Time

Cycle time is influenced by factors such as machine speed, process efficiency, and operator skill, while dwell time depends largely on cooling periods, material setting, and safety requirements. Variability in equipment performance and workflow consistency directly affects cycle time, whereas product complexity and quality control measures significantly impact dwell time. Optimizing both metrics requires balancing production speed with necessary pauses for material stabilization and inspection.

How to Calculate Cycle Time and Dwell Time

Cycle time is calculated by measuring the total time taken to complete one full process or production cycle, from start to finish, including active and idle times. Dwell time is determined by quantifying the duration a tool, machine, or product remains stationary or inactive during a specific phase within the cycle. Accurate measurement of cycle time and dwell time requires time tracking tools, such as stopwatches, sensors, or automated systems, to collect precise timestamps for process start, stop, and hold periods.

Common Misconceptions about Cycle Time and Dwell Time

Cycle time and dwell time are often confused, but cycle time refers to the total duration to complete one full process or operation, while dwell time specifically measures the period an item remains idle within a system. A common misconception is treating dwell time as part of productive time, which skews efficiency analysis and hinders process optimization. Accurate distinction between these metrics is essential for precise workflow management and reducing bottlenecks in manufacturing or service environments.

Industry Applications: Cycle Time vs Dwell Time in Practice

Cycle time and dwell time are critical metrics in manufacturing and production industries, where cycle time measures the total time to complete one process cycle, directly impacting throughput and efficiency. Dwell time refers to the period a workpiece remains at a specific station or step, influencing equipment utilization and quality control in automotive assembly, semiconductor fabrication, and packaging lines. Optimizing cycle time reduces lead times and operational costs, while managing dwell time ensures precision and minimizes bottlenecks in complex industrial workflows.

Best Practices for Reducing Cycle Time and Dwell Time

Reducing cycle time and dwell time requires streamlining workflows by implementing lean manufacturing principles such as value stream mapping and eliminating non-value-added activities. Incorporating automation and real-time data monitoring enhances process efficiency and minimizes delays during transitions. Continuous operator training and preventive maintenance ensure equipment reliability, further shortening cycle and dwell times for improved productivity.

Cycle time Infographic

libterm.com

libterm.com