Work hardening enhances a material's strength and durability by increasing dislocation density through plastic deformation. This process is critical in metal forming and manufacturing applications to improve resistance to wear and fatigue. Discover how work hardening can optimize your material's performance in the rest of the article.

Table of Comparison

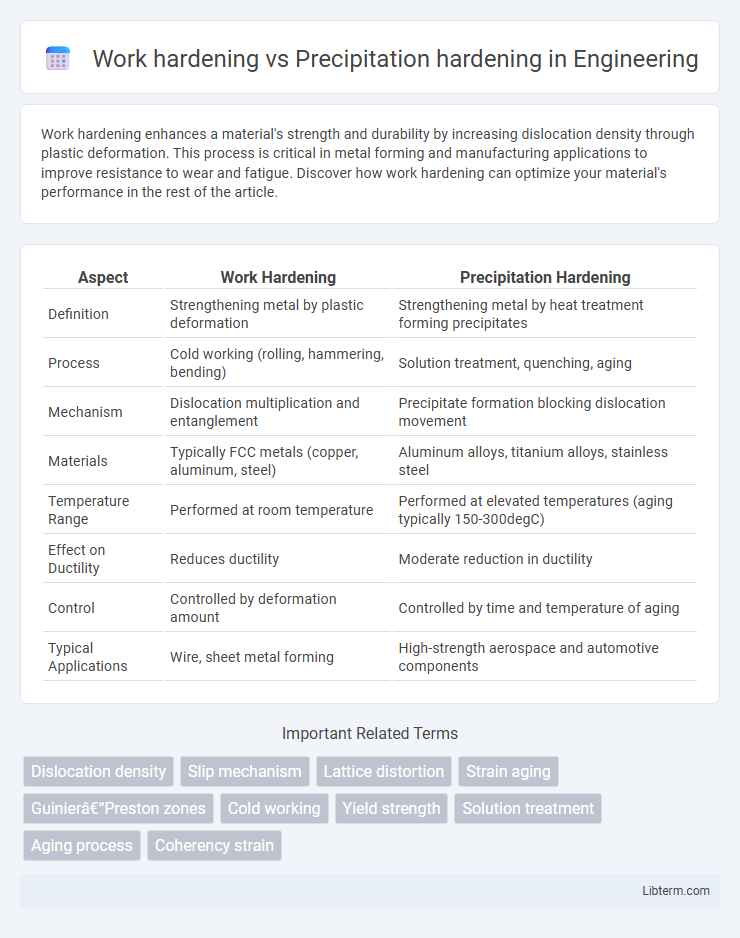

| Aspect | Work Hardening | Precipitation Hardening |

|---|---|---|

| Definition | Strengthening metal by plastic deformation | Strengthening metal by heat treatment forming precipitates |

| Process | Cold working (rolling, hammering, bending) | Solution treatment, quenching, aging |

| Mechanism | Dislocation multiplication and entanglement | Precipitate formation blocking dislocation movement |

| Materials | Typically FCC metals (copper, aluminum, steel) | Aluminum alloys, titanium alloys, stainless steel |

| Temperature Range | Performed at room temperature | Performed at elevated temperatures (aging typically 150-300degC) |

| Effect on Ductility | Reduces ductility | Moderate reduction in ductility |

| Control | Controlled by deformation amount | Controlled by time and temperature of aging |

| Typical Applications | Wire, sheet metal forming | High-strength aerospace and automotive components |

Introduction to Work Hardening and Precipitation Hardening

Work hardening, also known as strain hardening, increases a metal's strength and hardness by plastic deformation at temperatures below its recrystallization point, causing dislocation density to rise and obstructing further movement. Precipitation hardening, or age hardening, enhances mechanical properties through controlled heat treatments that form fine, dispersed particles (precipitates) within the metal matrix, impeding dislocation motion. Both processes are crucial in metallurgy for improving material performance but rely on fundamentally different mechanisms--work hardening modifies microstructure via deformation, while precipitation hardening alters phase composition through thermal activation.

Defining Work Hardening: Process and Principles

Work hardening, also known as strain hardening, is the process of strengthening a metal by plastic deformation, which increases dislocation density and impedes further dislocation movement, thereby enhancing the material's yield strength and hardness. This mechanism relies on cold working techniques such as rolling, hammering, or bending to induce lattice distortions and create internal stresses within the crystal structure. Unlike precipitation hardening that involves the formation of fine particles to obstruct dislocation motion, work hardening depends solely on deforming the metal to improve mechanical properties through microstructural changes.

Understanding Precipitation Hardening: Mechanism and Applications

Precipitation hardening, also known as age hardening, involves the formation of fine particles within a metal matrix that obstruct dislocation movement, significantly enhancing strength and hardness. This process typically consists of solution treatment, quenching, and aging, enabling alloys such as aluminum, titanium, and nickel-based superalloys to achieve superior mechanical properties and improved wear resistance. Precipitation hardening is extensively utilized in aerospace, automotive, and structural applications where high strength-to-weight ratios and durability are critical.

Key Differences Between Work Hardening and Precipitation Hardening

Work hardening increases metal strength through plastic deformation, introducing dislocations that hinder further movement, while precipitation hardening enhances strength by forming fine particles that obstruct dislocation movement within the alloy matrix. Work hardening is typically achieved by mechanical processes like rolling or hammering, and precipitation hardening involves heat treatment at specific temperatures to precipitate secondary phases. The resulting microstructure in work hardening is dominated by dislocation density, whereas precipitation hardening results in a dispersion of nanoscale precipitates that provide superior strength and hardness.

Materials Commonly Subjected to Work Hardening

Materials commonly subjected to work hardening include metals such as copper, aluminum, stainless steel, and brass, which exhibit increased strength and hardness through plastic deformation. In contrast, precipitation hardening primarily applies to alloys like aluminum-copper, nickel-aluminum, and certain stainless steels, where heat treatment induces fine precipitates that hinder dislocation movement. Work hardening enhances mechanical properties by dislocation density increase, whereas precipitation hardening relies on controlled aging processes to form strengthening phases.

Alloys and Metals Enhanced by Precipitation Hardening

Precipitation hardening significantly enhances alloys such as aluminum, titanium, and nickel-based superalloys by forming fine particles that obstruct dislocation motion, resulting in increased strength and hardness. Unlike work hardening, which relies on dislocation density increase through plastic deformation, precipitation hardening optimizes the microstructure through controlled heat treatments that promote solute atom clustering. This process is critical in aerospace and automotive industries where high strength-to-weight ratios and durability of materials like 7075 aluminum and Inconel are essential.

Effect on Mechanical Properties: Strength, Ductility, and Toughness

Work hardening increases strength by dislocation density enhancement but reduces ductility and toughness due to accumulated lattice distortions. Precipitation hardening elevates strength by forming fine, dispersed particles that impede dislocation motion while retaining higher ductility and toughness compared to work-hardened metals. The balance between strength and ductility is more favorable in precipitation hardening, making it preferable for applications requiring both strength and toughness.

Industrial Applications: Where Each Hardening Method Excels

Work hardening excels in industrial applications requiring enhanced surface strength and wear resistance, such as in metal forming and machining tools, due to its ability to increase dislocation density within the metal lattice. Precipitation hardening is preferred in aerospace and automotive industries for creating high-strength, lightweight alloys like aluminum and titanium by forming finely dispersed precipitates that hinder dislocation movement. Each method's effectiveness depends on desired material properties and processing conditions, with work hardening ideal for immediate surface strengthening and precipitation hardening suited for controlled thermal treatments producing uniform internal strengthening.

Advantages and Limitations of Work and Precipitation Hardening

Work hardening enhances material strength through dislocation generation and entanglement during plastic deformation, offering improved hardness and wear resistance without altering composition, but it is limited by reduced ductility and the potential for brittleness under excessive strain. Precipitation hardening increases strength by forming finely dispersed particles within the metal matrix that impede dislocation movement, providing superior strength-to-weight ratio and good corrosion resistance; however, it requires precise heat treatment control and may result in reduced toughness. Both methods improve mechanical properties but differ in application due to work hardening's simplicity and immediate effect versus precipitation hardening's dependence on alloy chemistry and thermal processing.

Choosing the Right Hardening Method for Specific Engineering Needs

Work hardening involves deforming a metal to increase dislocation density, enhancing strength without altering composition, ideal for applications requiring improved ductility and toughness. Precipitation hardening introduces fine particles through heat treatment to hinder dislocation movement, offering superior strength and hardness valuable in aerospace and automotive industries. Selecting the right method depends on engineering needs such as desired mechanical properties, component complexity, and thermal exposure during service.

Work hardening Infographic

libterm.com

libterm.com