Thermal relays protect electrical circuits by detecting overheating caused by excessive current. These devices use a bimetallic strip that bends when heated, triggering a switch to interrupt the circuit and prevent damage. Discover how thermal relays safeguard your equipment and ensure operational safety in the rest of this article.

Table of Comparison

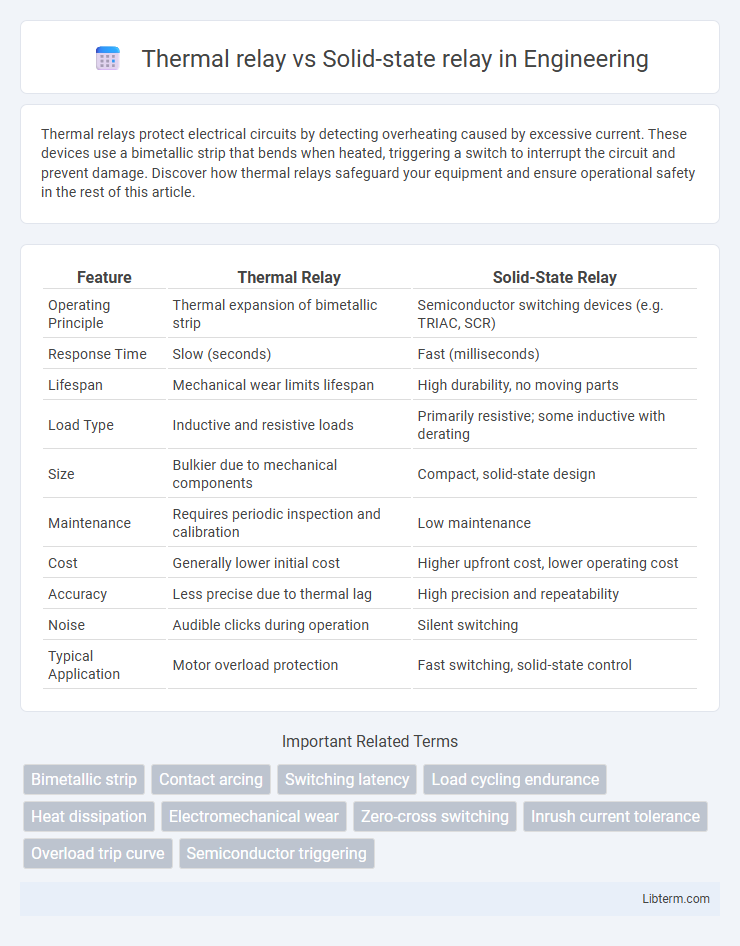

| Feature | Thermal Relay | Solid-State Relay |

|---|---|---|

| Operating Principle | Thermal expansion of bimetallic strip | Semiconductor switching devices (e.g. TRIAC, SCR) |

| Response Time | Slow (seconds) | Fast (milliseconds) |

| Lifespan | Mechanical wear limits lifespan | High durability, no moving parts |

| Load Type | Inductive and resistive loads | Primarily resistive; some inductive with derating |

| Size | Bulkier due to mechanical components | Compact, solid-state design |

| Maintenance | Requires periodic inspection and calibration | Low maintenance |

| Cost | Generally lower initial cost | Higher upfront cost, lower operating cost |

| Accuracy | Less precise due to thermal lag | High precision and repeatability |

| Noise | Audible clicks during operation | Silent switching |

| Typical Application | Motor overload protection | Fast switching, solid-state control |

Introduction to Thermal Relay and Solid-State Relay

Thermal relays protect electrical circuits by detecting excessive current through a bimetal strip that bends when heated, initiating a mechanical switch to break the circuit. Solid-state relays (SSRs) utilize semiconductor components like thyristors or transistors to perform switching without moving parts, offering faster response times and enhanced durability. Both devices serve as protective relays but differ significantly in operation, reliability, and application in industrial control systems.

Basic Working Principles

Thermal relays operate using a bimetallic strip that bends when heated by an electric current, triggering a mechanical switch to protect circuits from overload. Solid-state relays use semiconductor components like thyristors or triacs to switch loads electronically without moving parts. The thermal relay's response is slower due to heat buildup, while the solid-state relay provides faster, silent switching with greater durability.

Key Differences in Operation

Thermal relays operate based on heat generated by current flow, using a bimetallic strip that bends when heated to break the circuit, providing overload protection through mechanical movement. Solid-state relays rely on semiconductor components such as thyristors or triacs to switch electrical loads without moving parts, offering faster response times and higher durability. The key operational difference lies in thermal relays' reliance on temperature changes for activation versus solid-state relays' use of electronic switching, resulting in varying applications and performance characteristics.

Advantages of Thermal Relays

Thermal relays offer superior protection for motors by accurately responding to overcurrent conditions through bimetallic strips that mimic motor heating, ensuring reliable overload detection. They provide high sensitivity to gradual temperature changes, preventing motor damage with precise trip characteristics. Thermal relays are cost-effective, simple to maintain, and compatible with a wide range of motor types, making them ideal for industrial motor protection.

Advantages of Solid-State Relays

Solid-state relays (SSRs) offer faster switching speeds and longer operational lifespans compared to thermal relays due to the absence of mechanical moving parts. SSRs provide silent operation and higher resistance to vibration and shock, enhancing reliability in industrial automation and control systems. Their precise control with low power consumption and minimal electrical noise makes SSRs ideal for sensitive electronic devices and environments.

Applications: Where Each Type Excels

Thermal relays excel in motor protection applications where overload current sensing is critical, especially in industrial equipment requiring precise thermal monitoring to prevent winding damage. Solid-state relays are ideal for high-speed switching tasks in automation systems, semiconductor devices, and applications demanding silent, vibration-free operation with longer lifespan and faster response times. Each type's unique characteristics dictate their use: thermal relays for robust overload protection in motors, and solid-state relays for efficient, rapid switching in sensitive electronic circuits.

Performance and Reliability Comparison

Thermal relays provide reliable overload protection by utilizing bimetallic strips that physically deform under heat, offering simple, cost-effective performance but slower response times and mechanical wear over repeated cycles. Solid-state relays (SSRs) deliver faster switching speeds and greater durability due to their semiconductor-based design, resulting in longer lifespan, no moving parts, and minimal maintenance requirements. SSRs excel in performance for high-frequency switching and harsh environments, while thermal relays remain favored for straightforward, lower-cost motor protection scenarios.

Energy Efficiency and Power Consumption

Thermal relays consume more energy due to mechanical components that generate heat and require continuous current flow to maintain operation, resulting in higher power loss. Solid-state relays (SSRs) use semiconductor devices, offering superior energy efficiency by minimizing heat generation and eliminating mechanical wear, thereby reducing overall power consumption. SSRs provide faster switching speeds and lower standby power, making them ideal for applications demanding energy-efficient power management.

Cost Analysis and Maintenance

Thermal relays generally have lower upfront costs but require frequent maintenance due to mechanical wear and contact degradation, increasing long-term expenses. Solid-state relays, while more expensive initially, offer minimal maintenance costs because they lack moving parts and have higher reliability, leading to cost savings over time. Evaluating total cost of ownership highlights solid-state relays' advantage in applications demanding durability and low maintenance.

Choosing the Right Relay for Your Application

Selecting the right relay depends on the specific requirements of the application, such as current rating, switching speed, and environmental conditions. Thermal relays excel in overload protection for motors by responding to temperature changes, making them ideal for heavy-duty industrial machinery. Solid-state relays offer faster switching, longer lifespan, and no mechanical wear, suitable for applications needing precise control and high reliability in automation systems.

Thermal relay Infographic

libterm.com

libterm.com