Shear cutting is a precise metalworking process that uses shear force to cut materials along a straight line, ensuring clean edges with minimal deformation. This technique is essential in manufacturing industries for shaping sheet metal, reducing waste, and improving efficiency. Explore the rest of the article to discover how shear cutting can optimize your production workflow.

Table of Comparison

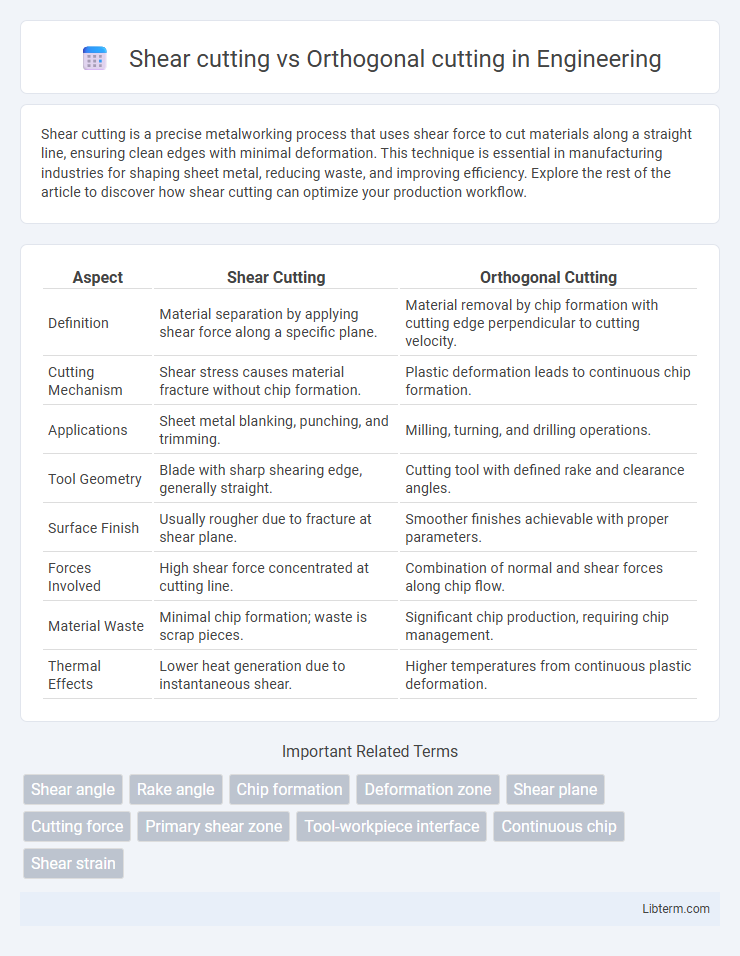

| Aspect | Shear Cutting | Orthogonal Cutting |

|---|---|---|

| Definition | Material separation by applying shear force along a specific plane. | Material removal by chip formation with cutting edge perpendicular to cutting velocity. |

| Cutting Mechanism | Shear stress causes material fracture without chip formation. | Plastic deformation leads to continuous chip formation. |

| Applications | Sheet metal blanking, punching, and trimming. | Milling, turning, and drilling operations. |

| Tool Geometry | Blade with sharp shearing edge, generally straight. | Cutting tool with defined rake and clearance angles. |

| Surface Finish | Usually rougher due to fracture at shear plane. | Smoother finishes achievable with proper parameters. |

| Forces Involved | High shear force concentrated at cutting line. | Combination of normal and shear forces along chip flow. |

| Material Waste | Minimal chip formation; waste is scrap pieces. | Significant chip production, requiring chip management. |

| Thermal Effects | Lower heat generation due to instantaneous shear. | Higher temperatures from continuous plastic deformation. |

Introduction to Cutting Methods

Shear cutting involves applying a force that causes material separation along a plane by inducing shear stress, commonly used in processes like blanking and punching. Orthogonal cutting describes a machining operation where the cutting edge moves perpendicular to the chip flow direction, optimizing material removal with defined shear zones and minimal cutting edge engagement. These cutting methods fundamentally differ in force application and chip formation, influencing machining efficiency and surface finish in manufacturing.

Defining Shear Cutting

Shear cutting is a machining process where material is separated by applying a shear force, causing deformation along a defined shear plane, typically resulting in a clean, precise cut with minimal burrs. Unlike orthogonal cutting, which involves a single-blade tool engaging the workpiece at a 90-degree angle to the cutting direction, shear cutting emphasizes localized shear stress to facilitate material separation. Key advantages of shear cutting include reduced cutting forces and improved surface finish, making it ideal for thin sheet metal and delicate materials.

Understanding Orthogonal Cutting

Orthogonal cutting involves the removal of material with the cutting edge perpendicular to the cutting velocity, allowing precise analysis of forces and chip formation. It simplifies the study of metal cutting mechanics by focusing on two-dimensional deformation, enabling optimized tool geometry and cutting parameters. This process is fundamental for understanding shear plane angle, cutting forces, and chip flow, essential for improving machining efficiency and surface finish quality.

Key Differences Between Shear and Orthogonal Cutting

Shear cutting involves applying a shearing force that causes material deformation along a plane, often used for cutting sheets and thin sections with minimal burr formation. Orthogonal cutting, on the other hand, is characterized by a single cutting edge moving perpendicular to the workpiece surface, generating chips through plastic deformation and shearing. Key differences include the direction of cutting forces, chip formation mechanisms, and typical applications, where shear cutting is preferred for clean, precise cuts and orthogonal cutting for machining processes like turning or milling.

Material Deformation in Shear vs Orthogonal Cutting

Shear cutting involves a combination of shear stress and compressive forces causing material to undergo plastic deformation along the shear plane before fracture, resulting in a smooth separation with minimal burr formation. Orthogonal cutting primarily generates localized plastic deformation beneath the cutting edge, where the material experiences high compressive and shear stresses, forming a primary shear zone that dictates chip formation and surface finish. The key difference lies in the deformation mode: shear cutting emphasizes large-scale shear deformation over a plane, whereas orthogonal cutting concentrates deformation in a narrow shear zone with significant strain gradients.

Tools and Machine Requirements

Shear cutting requires specialized blades with sharp edges and machines capable of applying high shear force to precisely separate materials, often used in metal and sheet processing. Orthogonal cutting demands robust cutting tools, typically single-point tools made from high-speed steel or carbide, mounted on machines designed for controlled linear tool movement perpendicular to the cutting direction. Machine rigidity and tool material hardness are critical in both methods to withstand cutting forces and maintain dimensional accuracy.

Surface Finish and Quality Comparison

Shear cutting produces a smoother surface finish with minimal burr formation due to its shearing action that cleanly severs material, enhancing overall workpiece quality. Orthogonal cutting often results in rougher surfaces and more pronounced built-up edge, negatively impacting surface integrity and dimensional accuracy. In high-precision applications, shear cutting is preferred for superior surface finish and reduced post-processing requirements.

Applications of Shear Cutting

Shear cutting is widely used in manufacturing processes such as sheet metal fabrication, where precise and clean cuts are essential, including blanking, piercing, and trimming operations. It is ideal for producing components in automotive, aerospace, and appliance industries due to its ability to handle high-volume production with minimal material deformation. Shear cutting applications benefit from reduced tool wear and efficient separation of materials compared to orthogonal cutting, which is more focused on machining and shaping metals through a single cutting edge.

Applications of Orthogonal Cutting

Orthogonal cutting is widely used in machining processes such as turning, milling, and drilling, where precise control over chip formation and surface finish is essential. This cutting method is favored in manufacturing industries for producing metal components with minimal tool wear and improved dimensional accuracy. High-speed machining and microfabrication also benefit from orthogonal cutting due to its ability to generate consistent shear planes and reduce cutting forces.

Choosing the Right Cutting Method

Shear cutting is ideal for materials requiring minimal deformation and clean edges, such as thin metals and plastics, due to its angled cutting action that reduces cutting forces. Orthogonal cutting suits applications needing precise material removal and better surface finish, commonly used in turning and milling processes with perpendicular tool engagement. Selecting the right cutting method depends on factors like material type, desired edge quality, tool wear, and production speed to optimize efficiency and product quality.

Shear cutting Infographic

libterm.com

libterm.com