Nanoprecipitation is a widely used technique for synthesizing nanoparticles with controlled size and uniform distribution, vital for applications in drug delivery and material science. This method involves the rapid mixing of a polymer solution with a non-solvent, causing the polymer to precipitate as nanoscale particles. Discover how understanding the principles and parameters of nanoprecipitation can enhance your research outcomes by exploring the rest of this article.

Table of Comparison

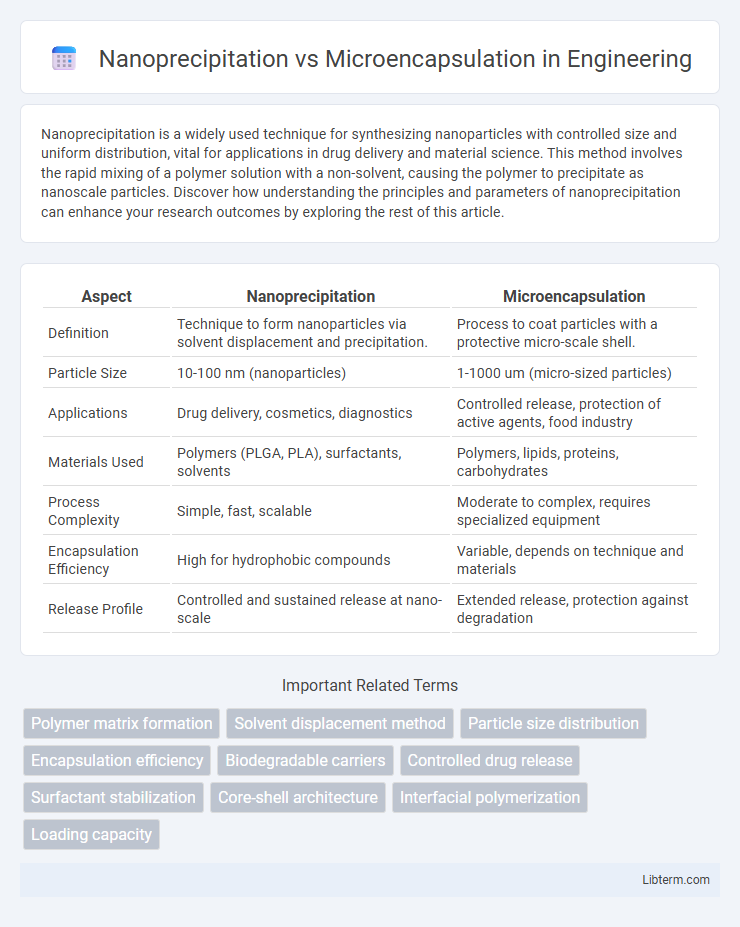

| Aspect | Nanoprecipitation | Microencapsulation |

|---|---|---|

| Definition | Technique to form nanoparticles via solvent displacement and precipitation. | Process to coat particles with a protective micro-scale shell. |

| Particle Size | 10-100 nm (nanoparticles) | 1-1000 um (micro-sized particles) |

| Applications | Drug delivery, cosmetics, diagnostics | Controlled release, protection of active agents, food industry |

| Materials Used | Polymers (PLGA, PLA), surfactants, solvents | Polymers, lipids, proteins, carbohydrates |

| Process Complexity | Simple, fast, scalable | Moderate to complex, requires specialized equipment |

| Encapsulation Efficiency | High for hydrophobic compounds | Variable, depends on technique and materials |

| Release Profile | Controlled and sustained release at nano-scale | Extended release, protection against degradation |

Introduction to Nanoprecipitation and Microencapsulation

Nanoprecipitation is a versatile technique used for the formation of polymeric nanoparticles by the controlled precipitation of polymers in a non-solvent, enabling the encapsulation of hydrophobic drugs with high efficiency and reproducibility. Microencapsulation involves the entrapment of active ingredients within microscale shells or matrices, offering protection, controlled release, and improved stability of bioactive compounds in pharmaceuticals and food industries. Both methods are pivotal in drug delivery systems, with nanoprecipitation favoring nanoscale precision and microencapsulation focusing on larger-scale encapsulation for diverse industrial applications.

Key Definitions and Concepts

Nanoprecipitation involves the formation of nanoparticles through the rapid mixing of a polymer solution with a non-solvent, resulting in spontaneous particle precipitation. Microencapsulation refers to the process of enclosing active substances within a microscale coating to protect and control their release. Nanoprecipitation creates particles typically below 200 nm, enhancing drug solubility and bioavailability, while microencapsulation provides controlled release profiles and stability at the microscale.

Process Overview: Nanoprecipitation

Nanoprecipitation involves dissolving a polymer and an active ingredient in a suitable solvent, followed by controlled addition into a non-solvent, causing rapid polymer precipitation and nanoparticle formation. This process enables precise control over particle size and distribution due to the diffusion-driven nanoparticle assembly. Nanoprecipitation is favored for producing uniform nanoparticles without requiring high energy input or complex equipment.

Process Overview: Microencapsulation

Microencapsulation involves the entrapment of active ingredients within a coating material to form micro-sized capsules, enhancing stability and controlled release. The process typically includes steps such as emulsification, coacervation, or spray drying, which allow precise encapsulation of bioactive compounds. This technique is widely used in pharmaceuticals, food, and agriculture to protect sensitive ingredients and improve targeted delivery.

Comparative Mechanisms of Particle Formation

Nanoprecipitation involves the rapid mixing of a polymer solution with a non-solvent, causing instantaneous polymer precipitation and formation of nanoparticles through nucleation and growth. Microencapsulation typically employs techniques like coacervation or spray drying, where active ingredients are encapsulated within a polymer matrix or shell, resulting in larger microsized particles. The fundamental difference lies in nanoprecipitation's reliance on solvent displacement for creating uniform nanoparticles, whereas microencapsulation focuses on forming protective microcapsules through physical or chemical phase separation processes.

Advantages and Limitations of Nanoprecipitation

Nanoprecipitation offers advantages such as simplicity, rapid preparation, and the ability to produce nanoparticles with narrow size distribution and high encapsulation efficiency. However, limitations include sensitivity to solvent selection, potential particle aggregation, and restricted suitability for hydrophilic drugs due to solvent compatibility issues. In contrast, microencapsulation provides better control over release profiles and protection of sensitive compounds but involves more complex and time-consuming processes.

Advantages and Limitations of Microencapsulation

Microencapsulation offers advantages such as controlled release, improved stability of sensitive active ingredients, and targeted delivery, enhancing efficacy in pharmaceuticals and food industries. Its limitations include relatively larger particle size compared to nanoprecipitation, potential for burst release, and complexity in scale-up processes for industrial production. Despite these challenges, microencapsulation remains valuable for applications requiring protection and gradual release of encapsulated substances.

Applications in Drug Delivery and Biotechnology

Nanoprecipitation enables the creation of uniform nanoparticles ideal for targeted drug delivery, enhancing bioavailability and controlled release of therapeutic agents. Microencapsulation offers versatile protection and sustained release of sensitive biomolecules and cells in biotechnology, improving stability and efficacy in treatments. Both techniques are pivotal in advancing drug delivery systems and biotechnological applications through tailored particle size and release profiles.

Factors Influencing Selection Between Methods

Nanoprecipitation is preferred for producing nanoparticles with controlled size and high drug loading efficiency, especially when working with hydrophobic drugs, whereas microencapsulation is ideal for encapsulating larger payloads or achieving sustained release profiles. Key factors influencing the selection include the nature of the active pharmaceutical ingredient, desired particle size, release kinetics, solvent compatibility, and process scalability. Material properties, such as polymer solubility and stability, also play critical roles in determining whether nanoprecipitation or microencapsulation is the optimal formulation approach.

Future Trends and Innovations in Encapsulation Technologies

Nanoprecipitation advances encapsulation technology by enabling precise control over nanoparticle size and release kinetics, fostering innovations in targeted drug delivery and diagnostics. Microencapsulation techniques are evolving with stimuli-responsive polymers and biodegradable materials that enhance payload stability and controlled release under specific physiological conditions. Future trends emphasize integrating artificial intelligence and machine learning to optimize formulation design, and scalable manufacturing processes to meet growing demand in pharmaceuticals, agriculture, and food industries.

Nanoprecipitation Infographic

libterm.com

libterm.com