The root circle is a crucial concept in gear design, representing the circle that marks the bottom of the tooth spaces on a gear. Understanding the root circle helps ensure proper gear meshing, reducing wear and increasing the lifespan of your mechanical systems. Explore the full article to learn how the root circle influences gear performance and maintenance.

Table of Comparison

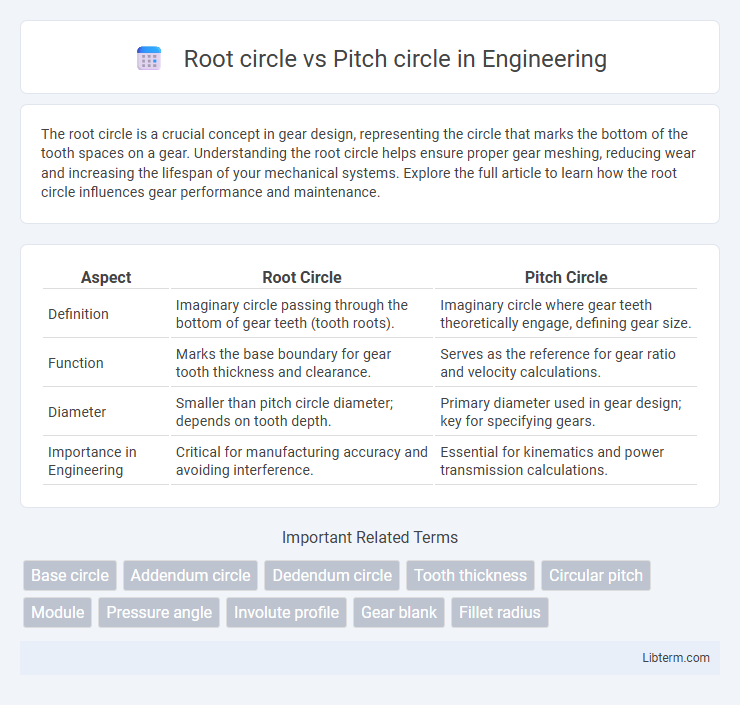

| Aspect | Root Circle | Pitch Circle |

|---|---|---|

| Definition | Imaginary circle passing through the bottom of gear teeth (tooth roots). | Imaginary circle where gear teeth theoretically engage, defining gear size. |

| Function | Marks the base boundary for gear tooth thickness and clearance. | Serves as the reference for gear ratio and velocity calculations. |

| Diameter | Smaller than pitch circle diameter; depends on tooth depth. | Primary diameter used in gear design; key for specifying gears. |

| Importance in Engineering | Critical for manufacturing accuracy and avoiding interference. | Essential for kinematics and power transmission calculations. |

Understanding Root Circle and Pitch Circle

The root circle in gear design represents the circle that passes through the bottom of the gear teeth, defining the deepest point of the tooth space and ensuring sufficient clearance between mating gears. The pitch circle is an imaginary circle that rolls without slipping with the pitch circle of a mating gear, serving as the fundamental reference for gear size and tooth geometry. Understanding the root circle and pitch circle is crucial for calculating gear dimensions, tooth thickness, and ensuring smooth power transmission in mechanical systems.

Definition of Root Circle

The root circle is the inner boundary of a gear tooth, representing the circle that passes through the bottom of the tooth spaces, while the pitch circle is an imaginary circle that defines the gear's effective diameter where teeth theoretically engage. The root circle plays a critical role in determining the gear's tooth depth and clearance, impacting strength and wear resistance. Understanding the distinction between the root circle and pitch circle is essential for accurate gear design and performance analysis.

Definition of Pitch Circle

Pitch circle refers to an imaginary circle on a gear or spline where the teeth theoretically engage, representing the point of contact and effective diameter for gear calculations. The root circle, by contrast, is the circle passing through the bottom of the gear tooth spaces, defining the inner limit of the gear tooth profile. Understanding the pitch circle is crucial for determining gear ratios, speed, and torque transmission in mechanical systems.

Key Differences Between Root Circle and Pitch Circle

The root circle is the circle that touches the bottom of the gear teeth, defining the gear's root diameter, while the pitch circle is an imaginary circle that represents the point where two gears effectively transmit motion without slipping and defines the pitch diameter. The root circle is always smaller than the pitch circle, as it forms the base of the tooth, whereas the pitch circle is used for calculating gear ratios and speeds. The root circle influences the gear's strength and clearance, whereas the pitch circle determines the gear's operational performance and meshing accuracy.

Importance of Root Circle in Gear Design

The root circle in gear design defines the bottom of the tooth space and is critical for ensuring adequate clearance and avoiding interference during meshing, directly impacting gear durability and performance. Unlike the pitch circle, which represents the theoretical contact line for smooth power transmission, the root circle determines the minimum gear thickness at the tooth base, influencing stress distribution and fatigue life. Proper specification of the root circle radius helps prevent tooth breakage and ensures reliable operation under load conditions, making it essential for robust gear design.

Significance of Pitch Circle in Gear Mechanics

The pitch circle in gear mechanics represents the theoretical circle where two gears effectively engage and transfer motion without slipping, ensuring accurate speed ratios and torque transmission. Unlike the root circle, which defines the base of the gear teeth, the pitch circle determines the gear's size and influences meshing characteristics and load distribution. Its significance lies in enabling precise gear alignment, optimizing efficiency, and minimizing wear in mechanical systems.

Calculation Methods for Root and Pitch Circles

The root circle diameter is calculated by subtracting twice the dedendum from the pitch circle diameter, where dedendum is typically the addendum plus clearance. The pitch circle diameter is derived from the number of teeth and the module, using the formula: pitch circle diameter = number of teeth x module. Accurate determination of root and pitch circles is essential for gear design, affecting meshing and load distribution.

Common Applications and Use Cases

Root circle and pitch circle are critical in gear design, with the root circle defining the bottom of the gear tooth and the pitch circle representing the theoretical contact point for meshing gears. Root circles are essential in determining the gear's strength and clearance, commonly applied in load-bearing calculations and wear assessment across automotive transmissions and industrial machinery. Pitch circles serve as the basis for gear ratio calculations and speed synchronization, widely used in robotics, aerospace mechanisms, and precision instrumentation.

Impact on Gear Performance and Efficiency

The root circle defines the minimum diameter of the gear, impacting the tooth's strength and load capacity, while the pitch circle represents the effective diameter where gear teeth engage, directly influencing transmission ratio and smoothness. A larger root circle diameter generally enhances durability by reducing stress concentration at the tooth root, improving gear life under high loads. Optimizing the pitch circle diameter ensures precise meshing and efficient power transfer, minimizing friction losses and enhancing overall gear performance.

Frequently Asked Questions on Root and Pitch Circles

The root circle is the circle that touches the bottom of the gear teeth, defining the gear's inner boundary, while the pitch circle is an imaginary circle where the gear teeth theoretically engage with a mating gear, crucial for calculating gear ratios and velocity. A common FAQ is the difference between these circles: the root circle determines the gear's strength at the base of the teeth, whereas the pitch circle influences the gear's size and speed relationship. Another frequent question is how these circles affect gear design; the root circle ensures clearance to avoid interference, and the pitch circle helps maintain proper meshing and smooth transmission of motion.

Root circle Infographic

libterm.com

libterm.com