Spiral heat exchangers offer efficient heat transfer by utilizing a compact design where fluids flow through spiral channels, maximizing surface area and minimizing fouling. Their robust construction allows for handling viscous fluids and slurries, making them ideal for industries such as chemical processing and food production. Explore the article to discover how a spiral heat exchanger can optimize your thermal management needs.

Table of Comparison

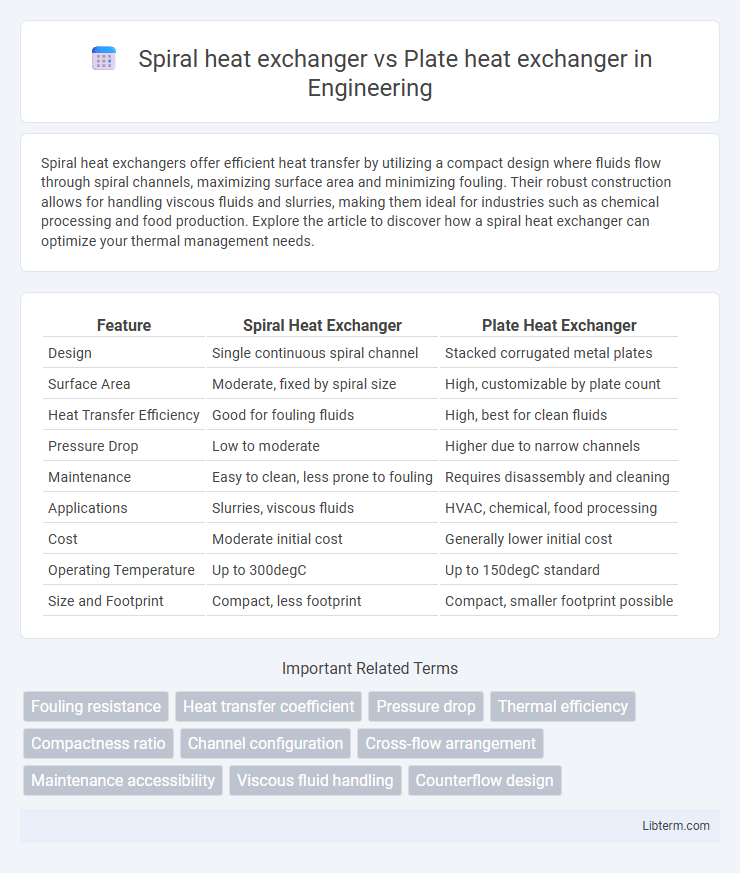

| Feature | Spiral Heat Exchanger | Plate Heat Exchanger |

|---|---|---|

| Design | Single continuous spiral channel | Stacked corrugated metal plates |

| Surface Area | Moderate, fixed by spiral size | High, customizable by plate count |

| Heat Transfer Efficiency | Good for fouling fluids | High, best for clean fluids |

| Pressure Drop | Low to moderate | Higher due to narrow channels |

| Maintenance | Easy to clean, less prone to fouling | Requires disassembly and cleaning |

| Applications | Slurries, viscous fluids | HVAC, chemical, food processing |

| Cost | Moderate initial cost | Generally lower initial cost |

| Operating Temperature | Up to 300degC | Up to 150degC standard |

| Size and Footprint | Compact, less footprint | Compact, smaller footprint possible |

Introduction to Spiral and Plate Heat Exchangers

Spiral heat exchangers feature a unique design with two flat metal plates wound around a central core, creating spiral channels that enhance heat transfer efficiency and allow handling of fouling fluids and slurries. Plate heat exchangers consist of multiple thin, corrugated metal plates stacked together, forming parallel flow channels that provide a large surface area for rapid heat exchange in compact spaces. Both types are widely used in industries like chemical processing, food and beverage, and HVAC, but spiral heat exchangers excel in handling viscous fluids and solids-laden streams, while plate heat exchangers offer flexibility in capacity and ease of maintenance.

Basic Principles of Heat Exchanger Operation

Spiral heat exchangers utilize a single, continuous spiral channel for fluids to flow in counter-current paths, maximizing heat transfer efficiency through a compact design and turbulent flow. Plate heat exchangers consist of multiple thin, corrugated metal plates stacked to create parallel flow channels, promoting high heat transfer rates via large surface area and turbulent flow induced by plate patterns. Both types operate on the principle of transferring thermal energy between two fluids without mixing, using conduction through metal surfaces and convection within the fluids.

Design and Construction Differences

Spiral heat exchangers feature a single or double spiral channel wrapped around a central core, allowing for efficient handling of fouling fluids and high viscosity materials due to their self-cleaning design and uniform flow distribution. Plate heat exchangers consist of multiple thin, corrugated metal plates stacked together, creating numerous parallel flow channels that promote high heat transfer efficiency through increased surface area and turbulent flow. While spiral heat exchangers generally offer robust construction with fewer joints and lower pressure drops, plate heat exchangers provide modularity and ease of maintenance through removable plates.

Heat Transfer Efficiency Comparison

Spiral heat exchangers offer higher heat transfer efficiency due to their continuous spiral flow path, which promotes turbulent flow and reduces fouling, enhancing thermal performance. Plate heat exchangers provide effective heat transfer through multiple thin plates creating a large surface area and thin fluid films, enabling rapid temperature changes. However, spiral designs generally maintain efficiency better under fouling conditions, making them suitable for viscous or particulate-laden fluids.

Space and Installation Requirements

Spiral heat exchangers offer compact designs with a smaller footprint, making them ideal for installations with limited space. Plate heat exchangers require more room due to their larger surface area and gasketed frame construction, but they provide easier access for maintenance and cleaning. The spiral model's integration reduces installation complexity and costs, especially in confined industrial environments.

Maintenance and Cleaning Considerations

Spiral heat exchangers feature a self-cleaning design with narrow channels that reduce fouling and require less frequent maintenance compared to plate heat exchangers, which have multiple gaskets and narrow channels prone to clogging and biofouling. Plate heat exchangers allow for easier disassembly and manual cleaning due to their modular construction, making them suitable for processes with frequent cleaning cycles. Maintenance for spiral heat exchangers often involves chemical cleaning and less frequent mechanical intervention, optimizing uptime in industries like wastewater treatment and chemical processing.

Suitability for Fluids and Applications

Spiral heat exchangers are highly suitable for handling viscous fluids, slurry, and fluids with high fouling tendencies due to their self-cleaning design and continuous flow paths. Plate heat exchangers excel in applications requiring efficient heat transfer for clean, low-viscosity fluids such as water, oils, and chemicals, offering easy maintenance and modular expansion. Industries like wastewater treatment and pulp processing commonly use spiral heat exchangers, while HVAC, food processing, and pharmaceuticals favor plate heat exchangers for precise temperature control and compact design.

Pressure Drop and Flow Characteristics

Spiral heat exchangers exhibit lower pressure drop due to their continuous, curved flow path, which promotes uniform velocity distribution and reduces turbulence compared to plate heat exchangers. Plate heat exchangers, with their corrugated plates and narrow channels, create higher pressure drops but enhance turbulence, improving heat transfer coefficients for viscous or fouling fluids. The flow characteristics of spiral designs accommodate particulate-laden fluids better, minimizing clogging and maintaining stable pressure differentials, whereas plate heat exchangers require more frequent maintenance to address flow restrictions caused by fouling and pressure fluctuations.

Cost Analysis and Economic Factors

Spiral heat exchangers typically have lower initial costs due to their compact design and simpler manufacturing process compared to plate heat exchangers, which often require more expensive materials and labor-intensive assembly. However, plate heat exchangers offer higher heat transfer efficiency and easier maintenance, potentially reducing long-term operational costs despite their higher upfront investment. Economic factors such as installation space, energy consumption, and maintenance intervals play critical roles in determining the overall cost-effectiveness of both heat exchanger types.

Choosing the Right Heat Exchanger for Your Needs

Spiral heat exchangers offer superior fouling resistance and compact design ideal for handling viscous or particulate-laden fluids, making them suitable for wastewater treatment and slurry applications. Plate heat exchangers provide high heat transfer efficiency with easy maintenance and flexibility, perfect for food processing, HVAC, and refrigeration systems requiring frequent cleaning. Selecting the right heat exchanger depends on fluid properties, fouling tendencies, space constraints, and maintenance requirements.

Spiral heat exchanger Infographic

libterm.com

libterm.com