SCADA systems provide centralized monitoring and control for industrial processes, while PLCs serve as the primary devices executing real-time automation tasks. Understanding the interplay between SCADA and PLC technology is crucial for optimizing operational efficiency and ensuring system reliability. Explore this article to discover how integrating these components can enhance your industrial automation.

Table of Comparison

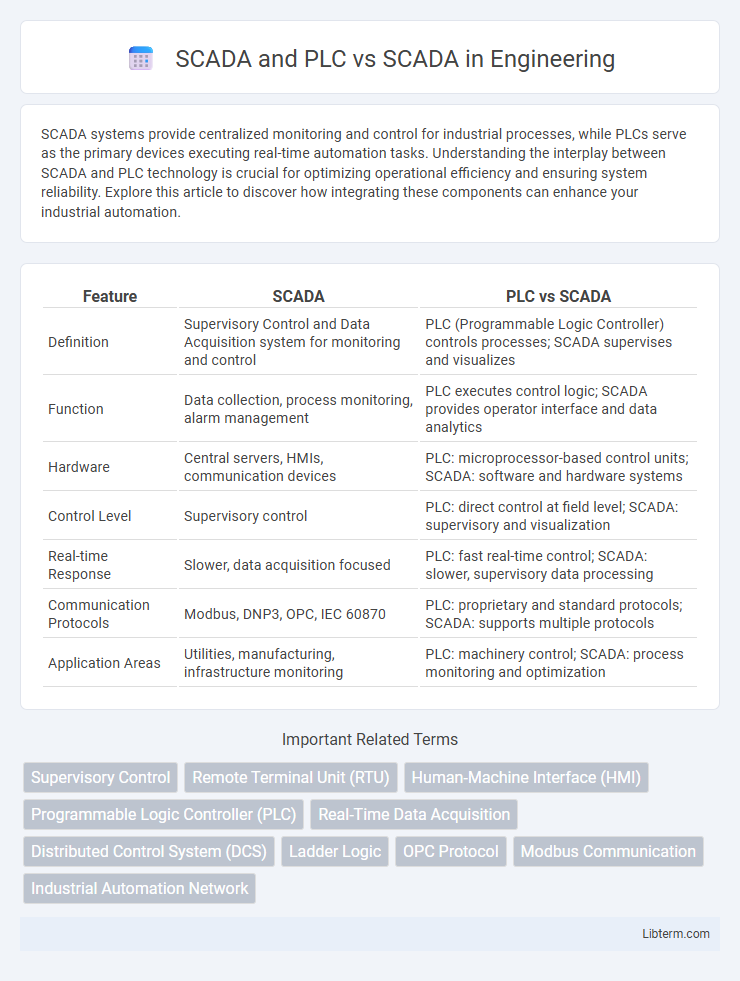

| Feature | SCADA | PLC vs SCADA |

|---|---|---|

| Definition | Supervisory Control and Data Acquisition system for monitoring and control | PLC (Programmable Logic Controller) controls processes; SCADA supervises and visualizes |

| Function | Data collection, process monitoring, alarm management | PLC executes control logic; SCADA provides operator interface and data analytics |

| Hardware | Central servers, HMIs, communication devices | PLC: microprocessor-based control units; SCADA: software and hardware systems |

| Control Level | Supervisory control | PLC: direct control at field level; SCADA: supervisory and visualization |

| Real-time Response | Slower, data acquisition focused | PLC: fast real-time control; SCADA: slower, supervisory data processing |

| Communication Protocols | Modbus, DNP3, OPC, IEC 60870 | PLC: proprietary and standard protocols; SCADA: supports multiple protocols |

| Application Areas | Utilities, manufacturing, infrastructure monitoring | PLC: machinery control; SCADA: process monitoring and optimization |

Introduction to SCADA and PLC

SCADA (Supervisory Control and Data Acquisition) is a system used for real-time monitoring and control of industrial processes, providing centralized data collection and analysis to enhance operational efficiency. PLC (Programmable Logic Controller) is a specialized industrial computer designed to automate machinery and processes through programmable logic control. SCADA systems rely on PLCs for direct control of equipment, while SCADA provides the overarching interface for monitoring, data acquisition, and supervisory control.

Core Functions of SCADA Systems

SCADA systems primarily focus on real-time data acquisition, monitoring, and control of industrial processes across multiple locations, enabling centralized supervision and efficient decision-making. PLCs function as localized controllers executing automated tasks through direct interaction with machinery and sensors, handling logic control and operational commands. SCADA integrates data from multiple PLCs to provide comprehensive visualization, alarming, and historical data analysis, enhancing overall system management and operational efficiency.

Understanding PLCs: Basics and Applications

PLCs (Programmable Logic Controllers) are specialized industrial computers designed for real-time automation and control of machinery, providing precise and reliable execution of programmed instructions. SCADA (Supervisory Control and Data Acquisition) systems focus on monitoring, data collection, and supervising industrial processes over large-scale operations, often integrating data from multiple PLCs. Understanding PLCs involves grasping their role in direct machine control, ladder logic programming, and applications across manufacturing, energy, and infrastructure sectors.

Key Differences: SCADA vs PLC

SCADA (Supervisory Control and Data Acquisition) systems provide centralized monitoring and control of complex industrial processes, while PLCs (Programmable Logic Controllers) are specialized hardware devices designed for real-time process automation and control. SCADA integrates data from multiple PLCs and other sensors to enable advanced visualization, historical data logging, and high-level decision making. The key difference lies in SCADA's role as a supervisory system managing overall operations versus PLCs executing specific control tasks at the device level.

Advantages of Integrating SCADA with PLC

Integrating SCADA with PLC systems enhances real-time monitoring and control capabilities, enabling precise automation across industrial processes. This integration improves data accuracy and system reliability by facilitating seamless communication between field devices and control centers. Enhanced fault detection and faster response times reduce downtime and optimize operational efficiency in manufacturing and infrastructure management.

SCADA Standalone: Capabilities and Limitations

SCADA standalone systems provide real-time monitoring and control of industrial processes without integrating PLCs, offering basic data acquisition and visualization capabilities. These systems excel in centralized supervisory functions but lack the advanced control, automation, and direct hardware interaction that PLCs deliver. Limitations include slower response times and reduced flexibility in complex automation tasks compared to combined SCADA and PLC configurations.

Use Cases: When to Use PLC Without SCADA

Programmable Logic Controllers (PLCs) are ideal for standalone automation tasks in industries like manufacturing and water treatment where real-time control and reliability are critical but remote monitoring is unnecessary. SCADA systems are beneficial when comprehensive data acquisition, system-wide monitoring, and supervisory control over multiple PLCs or devices are required, such as in large-scale power grids or oil and gas pipelines. Use cases for PLC without SCADA include simple machine control, local process automation, and environments with limited network infrastructure or where cost constraints prohibit implementing a full SCADA system.

SCADA and PLC Combined Architecture

SCADA and PLC combined architecture integrates Programmable Logic Controllers (PLCs) with Supervisory Control and Data Acquisition (SCADA) systems to enhance industrial automation and monitoring. PLCs execute real-time control tasks on machinery while SCADA provides centralized data acquisition, visualization, and remote control, enabling efficient process management. This hybrid structure improves system reliability, scalability, and response time in manufacturing, energy, and infrastructure sectors.

Industry Trends in Automation: SCADA vs PLC

SCADA (Supervisory Control and Data Acquisition) systems increasingly integrate advanced analytics and cloud computing to enhance real-time monitoring and decision-making in industrial automation. PLCs (Programmable Logic Controllers) remain essential for direct machine control and reliability but are evolving with IoT connectivity to support data exchange within SCADA architectures. Industry trends highlight a convergence where SCADA provides centralized supervision and data visualization, while PLCs execute precise control commands, creating a complementary ecosystem for efficient automated processes.

Choosing the Right Solution: SCADA, PLC, or Both

SCADA and PLC systems both play crucial roles in industrial automation, with SCADA offering centralized monitoring and control over large-scale processes, while PLCs provide real-time, localized control and automation of machinery. Choosing the right solution depends on the complexity and scale of the operation; SCADA systems excel in supervisory control, data acquisition, and remote management, whereas PLCs are ideal for fast, precise control tasks and direct interface with sensors and actuators. Combining SCADA and PLC technologies often delivers optimal performance by leveraging PLCs' automation strengths with SCADA's comprehensive visualization and data analytics capabilities.

SCADA and PLC Infographic

libterm.com

libterm.com