Rotary is a global humanitarian organization dedicated to promoting peace, fighting disease, supporting education, and advancing community development. Members collaborate on impactful projects that improve lives worldwide, emphasizing service above self. Discover how Your involvement with Rotary can make a meaningful difference by reading the rest of the article.

Table of Comparison

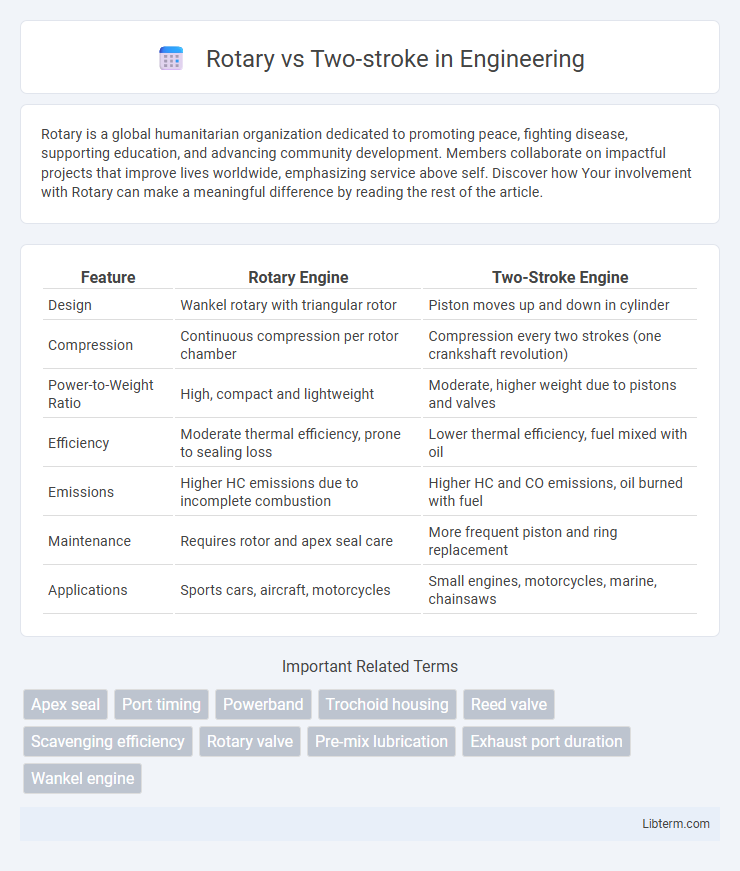

| Feature | Rotary Engine | Two-Stroke Engine |

|---|---|---|

| Design | Wankel rotary with triangular rotor | Piston moves up and down in cylinder |

| Compression | Continuous compression per rotor chamber | Compression every two strokes (one crankshaft revolution) |

| Power-to-Weight Ratio | High, compact and lightweight | Moderate, higher weight due to pistons and valves |

| Efficiency | Moderate thermal efficiency, prone to sealing loss | Lower thermal efficiency, fuel mixed with oil |

| Emissions | Higher HC emissions due to incomplete combustion | Higher HC and CO emissions, oil burned with fuel |

| Maintenance | Requires rotor and apex seal care | More frequent piston and ring replacement |

| Applications | Sports cars, aircraft, motorcycles | Small engines, motorcycles, marine, chainsaws |

Introduction to Rotary and Two-Stroke Engines

Rotary engines, also known as Wankel engines, use a triangular rotor spinning inside an epitrochoidal chamber to convert pressure into rotating motion, offering high power-to-weight ratios and smooth operation. Two-stroke engines complete a power cycle in two piston strokes, combining intake and exhaust processes, which makes them lightweight and simple but typically less fuel-efficient and higher in emissions. Both engine types are commonly used in applications where compactness and power density are critical, such as motorcycles, small aircraft, and specialized machinery.

Core Mechanical Differences

Rotary engines use a triangular rotor rotating inside an epitrochoid-shaped housing, converting pressure into rotational motion with fewer moving parts compared to conventional engines. Two-stroke engines operate via a piston moving up and down inside a cylinder, completing a power cycle with intake, compression, combustion, and exhaust occurring in two strokes. The rotary engine's continuous rotational motion provides smoother power delivery, while the two-stroke's reciprocating motion involves more vibrations and distinct power pulses.

Efficiency and Power Output

Rotary engines provide a higher power-to-weight ratio and smoother operation compared to two-stroke engines but often face challenges in fuel efficiency and emissions control. Two-stroke engines deliver high power output relative to engine size due to their firing frequency, yet their efficiency is lower because of incomplete combustion and fuel loss during the scavenging process. Overall, rotary engines excel in power density and smoother power delivery, while two-stroke engines are simpler and produce more power per displacement but at the cost of efficiency and higher emissions.

Fuel Consumption and Economy

Rotary engines typically consume more fuel than two-stroke engines due to their continuous rotary motion and larger surface area, which causes higher thermal losses and less efficient combustion. Two-stroke engines generally offer better fuel economy by firing once every revolution, providing more power strokes per cycle and improved fuel utilization. However, modern advancements in rotary engine technology, such as direct fuel injection and improved sealing materials, are narrowing the gap in fuel consumption and operational efficiency.

Durability and Maintenance

Rotary engines generally offer smoother operation and fewer moving parts, resulting in less frequent maintenance compared to two-stroke engines, which tend to wear out faster due to higher RPMs and the constant exposure of moving parts to fuel and combustion byproducts. Two-stroke engines require regular maintenance such as frequent oil changes, spark plug replacements, and piston ring inspections to maintain optimal performance, while rotary engines demand careful attention to apex seals to ensure engine durability. Durability in rotary engines can suffer if maintenance is neglected, but with proper care, rotary engines often outlast two-stroke engines in terms of overall service life.

Emissions and Environmental Impact

Rotary engines produce higher hydrocarbon emissions due to incomplete combustion compared to two-stroke engines, which emit significant amounts of unburned fuel and lubricating oil. Two-stroke engines generally contribute more to air pollution with elevated particulate matter and carbon monoxide levels, exacerbating environmental degradation. Advances in emission control technologies have improved rotary engine efficiency, but two-stroke engines remain more environmentally detrimental overall.

Applications in Automotive and Industry

Rotary engines excel in automotive applications due to their compact size, high power-to-weight ratio, and smooth operation, making them ideal for sports cars and racing vehicles. Two-stroke engines dominate in industrial uses such as chainsaws, motorcycles, and small machinery because of their simple design, lightweight construction, and efficient power delivery at high RPMs. While rotary engines offer better emissions control and durability for continuous automotive operation, two-stroke engines remain popular in portable and lightweight industrial equipment due to lower manufacturing costs and ease of maintenance.

Performance in Motorsports

Rotary engines deliver smooth power with a high power-to-weight ratio, making them favored in specific motorsports like rally and lightweight racing cars, where acceleration and compact design are crucial. Two-stroke engines excel in producing rapid power bursts due to their simpler design and higher RPM capabilities, commonly dominating in motocross and kart racing. Performance-wise, rotary motors provide consistent torque across a broad range, while two-strokes offer explosive power spikes ideal for quick throttle responses in short bursts.

Cost Comparison and Affordability

Rotary engines typically have higher initial purchase prices and maintenance costs compared to two-stroke engines, due to their complex design and specialized parts. Two-stroke engines are generally more affordable upfront and easier to repair, making them a cost-effective choice for budget-conscious users. Long-term affordability favors two-stroke engines, especially in applications where simplicity and lower operating expenses are prioritized.

Future Trends and Technological Advances

Rotary engines are experiencing innovation through advanced materials and improved thermal management, enhancing their efficiency and emissions control for future automotive applications. Two-stroke engines benefit from precise fuel injection and electronic control units, reducing pollution and increasing fuel economy, particularly in lightweight transport and power tools. Emerging trends emphasize hybrid integration and alternative fuels, positioning both engine types for sustainable performance in evolving energy landscapes.

Rotary Infographic

libterm.com

libterm.com