Globe valves regulate fluid flow with precise throttling capabilities, allowing efficient control in various piping systems. Their unique design includes a movable disk and a stationary ring seat, optimizing flow regulation and minimizing leakage. Explore the article to understand how a globe valve can enhance Your system's performance and reliability.

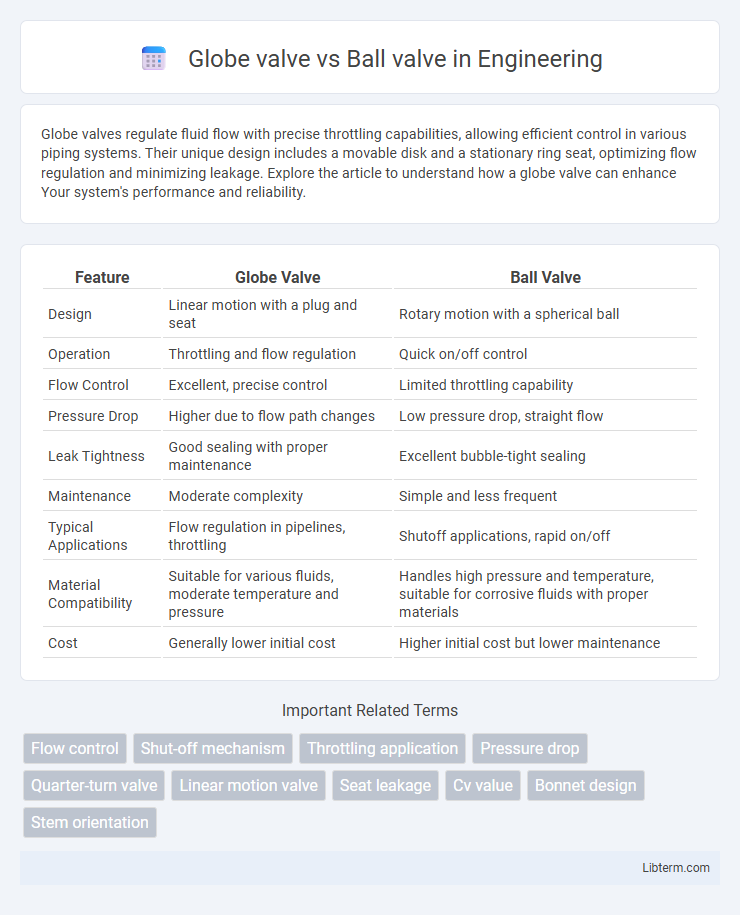

Table of Comparison

| Feature | Globe Valve | Ball Valve |

|---|---|---|

| Design | Linear motion with a plug and seat | Rotary motion with a spherical ball |

| Operation | Throttling and flow regulation | Quick on/off control |

| Flow Control | Excellent, precise control | Limited throttling capability |

| Pressure Drop | Higher due to flow path changes | Low pressure drop, straight flow |

| Leak Tightness | Good sealing with proper maintenance | Excellent bubble-tight sealing |

| Maintenance | Moderate complexity | Simple and less frequent |

| Typical Applications | Flow regulation in pipelines, throttling | Shutoff applications, rapid on/off |

| Material Compatibility | Suitable for various fluids, moderate temperature and pressure | Handles high pressure and temperature, suitable for corrosive fluids with proper materials |

| Cost | Generally lower initial cost | Higher initial cost but lower maintenance |

Introduction to Globe and Ball Valves

Globe valves regulate flow with a linear motion and feature a movable disk and a stationary ring seat, making them ideal for throttling and frequent operation. Ball valves use a rotary motion with a spherical closure unit having a hole through the center, enabling quick shutoff and reliable sealing in pipelines. Both valve types are essential in industrial fluid control applications, chosen based on flow control needs and operational functions.

Key Differences Between Globe and Ball Valves

Globe valves provide precise flow control due to their linear motion and throttling capabilities, making them ideal for applications requiring regulation and frequent operation. Ball valves offer quick shutoff with a 90-degree turn, featuring a spherical disc that ensures tight sealing and minimal pressure drop, suitable for on/off control in high-pressure systems. Key differences include globe valves' higher pressure drops and slower operation versus ball valves' efficiency in sealing and speed, influencing their selection based on flow control needs and system requirements.

Design and Structure Comparison

Globe valves feature a linear motion design with a disk that moves perpendicular to the seat, allowing precise flow regulation and throttling capabilities ideal for pressure control applications. Ball valves utilize a rotary motion with a hollow, perforated, and pivoting ball that provides tight sealing and quick shutoff, making them suitable for on/off control with minimal pressure drop. Structurally, globe valves have a more complex body with multiple seals and seats, whereas ball valves have a simpler, compact design with fewer components, enhancing durability and ease of maintenance.

Working Principles Explained

Globe valves regulate flow by moving a plug or disc perpendicular to the seat, creating a throttling effect that allows precise control of fluid flow. Ball valves use a rotating spherical ball with a bore to start or stop flow, providing a quick, quarter-turn shutoff with minimal pressure drop. The globe valve's linear motion suits applications requiring fine flow adjustment, while the ball valve's rotary motion ensures reliable, tight sealing for on/off control.

Flow Control Capabilities

Globe valves provide precise flow control due to their linear motion and throttling capability, making them ideal for applications requiring fine adjustments. Ball valves, with their quarter-turn operation, offer quick shut-off but less accurate flow modulation, better suited for on/off control. The choice depends on whether precise flow regulation (globe valve) or rapid valve operation with minimal pressure drop (ball valve) is prioritized.

Applications and Suitable Industries

Globe valves are ideal for applications requiring precise flow control, commonly used in water treatment, chemical processing, and power generation industries due to their throttling capability. Ball valves excel in sectors such as oil and gas, pharmaceuticals, and food processing where quick shut-off and minimal pressure drop are critical, offering reliable sealing in high-pressure environments. Both valve types serve essential roles but are chosen based on the industry's need for accuracy versus rapid isolation.

Durability and Maintenance Requirements

Globe valves typically exhibit higher durability in applications involving frequent throttling due to their robust construction and precise control capabilities, whereas ball valves offer superior longevity under conditions requiring tight shutoff and minimal wear. Maintenance for globe valves is more intensive because of their complex stem and seat design, necessitating regular inspection and component replacement to prevent leaks and wear. Ball valves demand less maintenance overall, featuring a simple quarter-turn mechanism and fewer moving parts, reducing downtime and service frequency.

Advantages of Globe Valves

Globe valves offer superior throttling capabilities and precise flow regulation compared to ball valves, making them ideal for applications requiring fine control. Their design minimizes leakage and provides reliable shut-off even under high-pressure conditions. Maintenance is straightforward due to their simple stem and seat assembly, enhancing durability and operational lifespan.

Advantages of Ball Valves

Ball valves offer superior sealing capabilities with a tight shut-off, reducing leakage risks in pipelines handling gases and liquids. Their quick quarter-turn operation enables fast opening and closing, enhancing efficiency in flow control systems. Durable construction and low-pressure drop design make ball valves ideal for high-pressure and high-temperature applications, outperforming globe valves in longevity and maintenance requirements.

How to Choose Between Globe and Ball Valves

Choosing between globe and ball valves depends on the application requirements, such as flow control precision and shutoff capability. Globe valves offer superior throttling and flow regulation due to their linear motion and disk design, making them ideal for modulating flow in pipelines. Ball valves provide quick, tight shutoff with minimal pressure drop, suitable for on/off control in systems requiring fast operation and durability.

Globe valve Infographic

libterm.com

libterm.com