Stepper motors provide precise control of rotational position, making them essential for applications requiring accurate movement like 3D printers and CNC machines. Their ability to move in discrete steps allows for repeatable and reliable positioning without the need for feedback systems. Explore the full article to understand how stepper motors can enhance your projects with exact motion control.

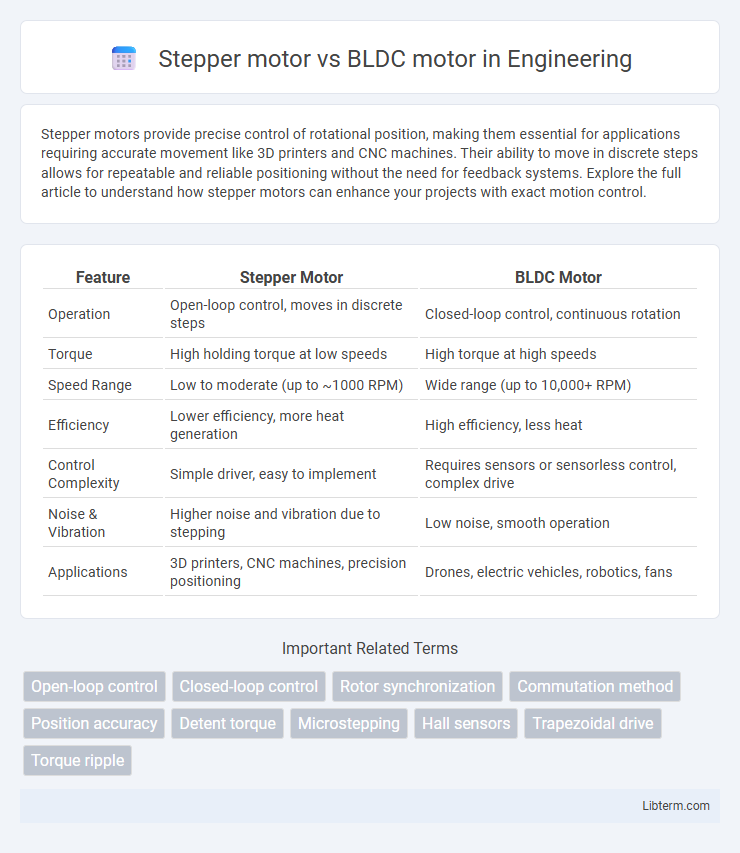

Table of Comparison

| Feature | Stepper Motor | BLDC Motor |

|---|---|---|

| Operation | Open-loop control, moves in discrete steps | Closed-loop control, continuous rotation |

| Torque | High holding torque at low speeds | High torque at high speeds |

| Speed Range | Low to moderate (up to ~1000 RPM) | Wide range (up to 10,000+ RPM) |

| Efficiency | Lower efficiency, more heat generation | High efficiency, less heat |

| Control Complexity | Simple driver, easy to implement | Requires sensors or sensorless control, complex drive |

| Noise & Vibration | Higher noise and vibration due to stepping | Low noise, smooth operation |

| Applications | 3D printers, CNC machines, precision positioning | Drones, electric vehicles, robotics, fans |

Introduction to Stepper and BLDC Motors

Stepper motors provide precise position control through discrete step movements, making them ideal for applications requiring accurate and repeatable positioning. BLDC motors utilize electronically commutated permanent magnets for smooth, high-efficiency rotation and are preferred in high-speed, dynamic applications due to their superior torque-to-weight ratio. Both motor types serve critical roles in automation, robotics, and industrial equipment, with stepper motors excelling in low-speed precision and BLDC motors in high-speed performance.

Working Principles: Stepper vs BLDC Motor

Stepper motors operate by energizing coils in a specific sequence, causing the rotor to move in discrete steps for precise position control without feedback. Brushless DC (BLDC) motors use electronic commutation driven by sensors or sensorless control to continuously rotate the rotor smoothly and efficiently by switching current in the stator windings. The stepper motor's open-loop control contrasts with the BLDC motor's closed-loop control, impacting torque delivery and speed performance.

Key Differences Between Stepper and BLDC Motors

Stepper motors provide precise position control by moving in fixed increments, making them ideal for applications requiring accurate and repeatable positioning. BLDC motors operate with continuous rotation and higher efficiency due to their electronic commutation, delivering smoother motion and higher speed capabilities. Key differences include control methods, torque characteristics, and efficiency, with steppers excelling in low-speed precision and BLDC motors favored for high-speed and variable torque applications.

Control Mechanisms in Stepper and BLDC Motors

Stepper motors utilize open-loop control mechanisms based on precise pulse signals to achieve discrete position increments, enabling accurate positioning without feedback sensors. BLDC motors employ closed-loop control systems with Hall effect sensors or sensorless back-EMF detection to continuously adjust commutation timing for smooth rotation and high efficiency. The fundamental difference lies in stepper motors' reliance on fixed step increments versus BLDC motors' dynamic rotor position feedback for speed and torque regulation.

Torque and Speed Characteristics

Stepper motors provide precise position control with high torque at low speeds, making them ideal for applications requiring accurate incremental movement. BLDC motors deliver higher efficiency and maintain torque across a wide speed range, offering superior performance at high rotational speeds. Torque in stepper motors tends to drop significantly as speed increases, whereas BLDC motors sustain consistent torque due to their continuous rotation and electronic commutation.

Precision and Positioning Capabilities

Stepper motors offer high precision in positioning due to their ability to move in discrete steps, typically ranging from 1.8deg to 0.9deg per step, making them ideal for applications requiring accurate, repeatable movements without feedback systems. BLDC motors provide smoother motion and higher speed capabilities but rely on external sensors or encoders for precise positioning, which can introduce complexity and cost. The inherent open-loop control of stepper motors ensures reliable, stable positioning in low-speed applications, while BLDC motors excel in dynamic environments demanding high efficiency and closed-loop feedback.

Efficiency and Power Consumption

Stepper motors typically exhibit lower efficiency due to continuous current flow in windings, resulting in higher power consumption even at standstill. BLDC motors, engineered with permanent magnets and electronic commutation, achieve superior efficiency by minimizing energy losses and optimizing torque output. Consequently, BLDC motors provide better power-to-performance ratios, making them ideal for applications demanding energy conservation.

Applications of Stepper Motors

Stepper motors are widely used in precision control applications such as 3D printers, CNC machines, and robotic arms due to their ability to achieve accurate position control without feedback systems. Their open-loop control and high torque at low speeds make them ideal for applications requiring incremental movement and repeatability. Industries like automation, medical devices, and textile manufacturing rely heavily on stepper motors for tasks involving precise positioning and speed control.

Applications of BLDC Motors

BLDC motors are widely used in applications requiring high efficiency and precise control, such as electric vehicles, drones, and computer hard drives. Their ability to provide high torque at low speeds makes them ideal for robotics and industrial automation. The low maintenance and long lifespan also contribute to their popularity in HVAC systems and medical devices.

Choosing the Right Motor for Your Project

Choosing the right motor for your project depends on factors such as precision, torque, speed, and efficiency. Stepper motors excel in applications requiring precise position control and low-speed torque, making them ideal for 3D printers and CNC machines. BLDC motors offer higher efficiency, smoother operation, and greater speed capabilities, suited for electric vehicles and drones where performance and energy savings are critical.

Stepper motor Infographic

libterm.com

libterm.com