Inclusion fosters diverse environments where every individual feels valued and respected, enhancing collaboration and innovation. By embracing different perspectives and backgrounds, organizations unlock greater creativity and problem-solving potential. Discover how inclusion can transform your community and workplace by reading the full article.

Table of Comparison

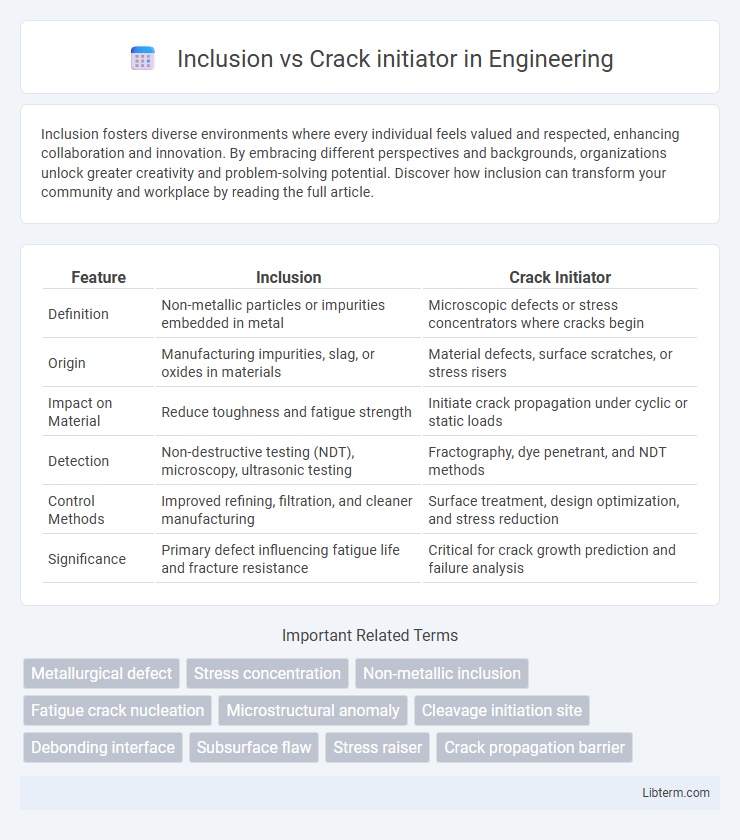

| Feature | Inclusion | Crack Initiator |

|---|---|---|

| Definition | Non-metallic particles or impurities embedded in metal | Microscopic defects or stress concentrators where cracks begin |

| Origin | Manufacturing impurities, slag, or oxides in materials | Material defects, surface scratches, or stress risers |

| Impact on Material | Reduce toughness and fatigue strength | Initiate crack propagation under cyclic or static loads |

| Detection | Non-destructive testing (NDT), microscopy, ultrasonic testing | Fractography, dye penetrant, and NDT methods |

| Control Methods | Improved refining, filtration, and cleaner manufacturing | Surface treatment, design optimization, and stress reduction |

| Significance | Primary defect influencing fatigue life and fracture resistance | Critical for crack growth prediction and failure analysis |

Understanding Inclusions and Crack Initiators

Inclusions are non-metallic particles or impurities embedded within a metal matrix that act as stress concentrators and weaken material integrity. Crack initiators often originate from these inclusions, where microvoids form under cyclic or tensile stresses, promoting crack nucleation and subsequent propagation. Understanding the morphology, size, and distribution of inclusions is critical in predicting and mitigating the initiation sites for fatigue cracks in engineering materials.

Key Differences Between Inclusions and Crack Initiators

Inclusions are non-metallic particles embedded within a material, often originating from manufacturing impurities, while crack initiators are specific sites or defects where fractures begin under stress. Inclusions act as stress concentrators that can weaken the material structure, whereas crack initiators are the precise points where microcracks develop and propagate. Understanding how inclusions serve as potential crack initiators is crucial for improving material fatigue resistance and preventing failure.

Origins and Types of Inclusions in Materials

Inclusions, typically non-metallic particles such as oxides, sulfides, or nitrides, originate during the steelmaking process from raw materials, slag entrapment, or deoxidation reactions and serve as common crack initiators due to their differing mechanical properties compared to the metal matrix. These inclusions vary in morphology and chemical composition, ranging from globular oxides to elongated sulfides, influencing stress concentration and crack propagation mechanisms. Understanding the origin and type of inclusions is critical for controlling material fatigue performance and preventing premature failure in engineering components.

How Crack Initiators Form in Engineering Structures

Crack initiators in engineering structures often originate from inclusions, which are foreign particles or defects embedded within the material matrix during manufacturing. These inclusions create localized stress concentrations that act as focal points for micro-crack formation under cyclic loading or environmental exposure. Understanding the size, distribution, and composition of inclusions is critical for predicting crack initiation and enhancing material fatigue resistance.

The Role of Inclusions in Material Failure

Inclusions act as stress concentration sites within materials, serving as primary crack initiators under cyclic or tensile loading conditions. Their presence disrupts the uniformity of the microstructure, leading to localized plastic deformation and eventual microcrack formation. Understanding the nature, size, and distribution of inclusions is critical for predicting and mitigating material failure mechanisms in engineering components.

Mechanisms by Which Crack Initiators Induce Fracture

Crack initiators induce fracture primarily by serving as stress concentrators that facilitate microvoid nucleation and crack propagation under cyclic or static loads. Inclusions act as flaws where localized plastic deformation and microcrack formation begin due to mismatches in mechanical properties and thermal expansion coefficients between the inclusion and the metal matrix. These mechanisms accelerate crack initiation by promoting localized strain, increasing the likelihood of fracture at lower applied stresses compared to defect-free regions.

Detection and Analysis of Inclusions vs Crack Initiators

Detection and analysis of inclusions as crack initiators involve advanced non-destructive testing methods such as ultrasonic testing, scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS) to identify microstructural anomalies. Inclusions often act as stress concentrators causing crack initiation under cyclic loading, making precise characterization critical for predicting fatigue life. Accurate differentiation between inclusions and cracks enables targeted material processing improvements and enhances structural integrity assessments in critical components.

Impact on Mechanical Properties and Performance

Inclusions act as stress concentrators and reduce ductility and toughness, often initiating cracks under cyclic or tensile loading, thereby degrading mechanical properties such as fatigue strength and impact resistance. Crack initiators are typically microstructural defects or inclusions where stress concentration reaches critical levels, accelerating crack propagation and leading to premature failure. The presence and size of inclusions significantly affect the initiation phase, influencing the overall performance and reliability of metallic components in fatigue-sensitive applications.

Prevention and Mitigation Strategies

Inclusion defects serve as common crack initiators in metal components, significantly impacting fatigue life and structural integrity. Prevention strategies emphasize rigorous control of raw material quality, advanced filtering during molten metal pouring, and refined casting processes to minimize inclusion formation. Mitigation involves ultrasonic inspection, non-destructive testing, and targeted heat treatments to detect and alleviate the effects of inclusions before service failure.

Future Trends in Reducing Inclusions and Crack Initiators

Advancements in metallurgical processes and real-time monitoring technologies are driving future trends in reducing inclusions and crack initiators in critical materials. Emerging techniques such as ultrasonic inspection, laser-induced breakdown spectroscopy (LIBS), and artificial intelligence-based defect prediction are enhancing the early detection and classification of micro-inclusions that contribute to crack initiation. Ongoing research in refining steel cleanliness through improved deoxidation methods and inclusion engineering aims to produce ultra-clean metals with higher resistance to fatigue and fracture.

Inclusion Infographic

libterm.com

libterm.com