Cross flow refers to the movement of air, liquid, or gas perpendicular to a surface or through a medium, commonly used in engineering and environmental systems for efficient heat exchange and ventilation. In industrial applications, cross flow designs enhance performance by improving fluid distribution and reducing energy consumption. Explore the rest of the article to discover how cross flow can optimize your systems for better efficiency and functionality.

Table of Comparison

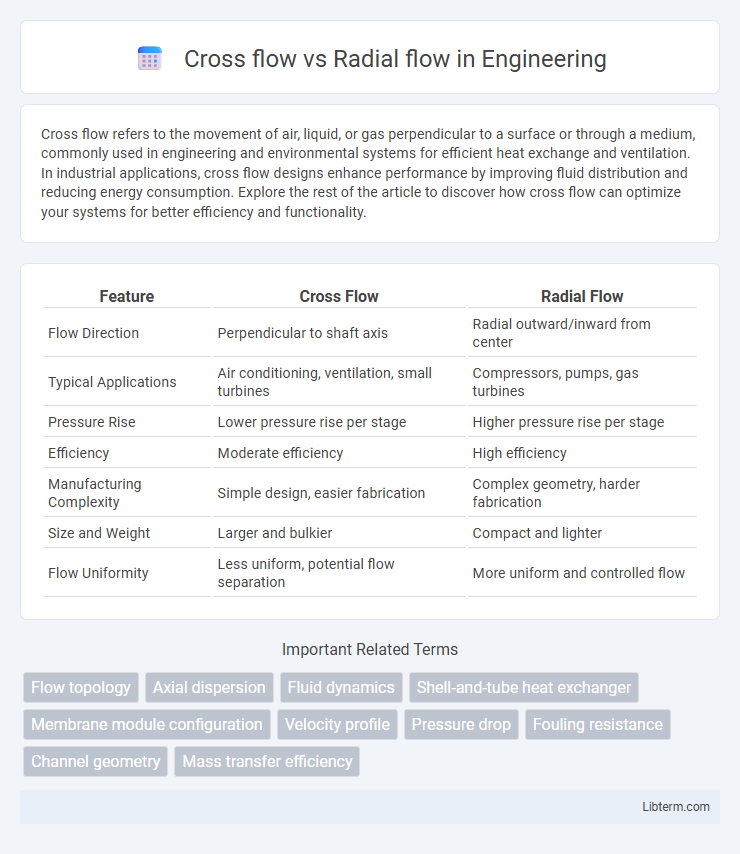

| Feature | Cross Flow | Radial Flow |

|---|---|---|

| Flow Direction | Perpendicular to shaft axis | Radial outward/inward from center |

| Typical Applications | Air conditioning, ventilation, small turbines | Compressors, pumps, gas turbines |

| Pressure Rise | Lower pressure rise per stage | Higher pressure rise per stage |

| Efficiency | Moderate efficiency | High efficiency |

| Manufacturing Complexity | Simple design, easier fabrication | Complex geometry, harder fabrication |

| Size and Weight | Larger and bulkier | Compact and lighter |

| Flow Uniformity | Less uniform, potential flow separation | More uniform and controlled flow |

Introduction to Cross Flow and Radial Flow

Cross flow and radial flow refer to distinct fluid dynamics patterns in heat exchangers and filtration systems. Cross flow involves fluid moving perpendicular to the flow of another medium, enhancing heat transfer efficiency by creating turbulent mixing and reducing boundary layers. Radial flow, characterized by fluid moving either inward or outward along a radial path, is commonly used in centrifugal pumps and compressors for uniform velocity distribution and improved pressure performance.

Defining Cross Flow: Key Characteristics

Cross flow involves fluid moving perpendicular to the membrane or surface, enhancing mass transfer by maintaining constant velocity across the flow channel. Key characteristics include uniform distribution, minimized fouling due to tangential velocity, and efficient heat or mass exchange, commonly used in filtration and heat exchanger systems. This flow pattern contrasts with radial flow, where fluid moves inward or outward along a radius, affecting pressure distribution and shear stress differently.

Understanding Radial Flow: Main Features

Radial flow pumps direct fluid perpendicularly from the pump's center toward the outer edges, creating efficient pressure generation and steady flow rates ideal for high-head applications. The impeller design in radial flow provides optimal kinetic energy conversion to pressure, making these pumps suitable for water supply, irrigation, and industrial processes. Their compact structure and ability to handle varying fluid viscosities highlight radial flow pumps' versatility in numerous engineering systems.

Core Differences Between Cross Flow and Radial Flow

Cross flow and radial flow differ fundamentally in fluid movement patterns; cross flow directs fluid perpendicular to the filter or membrane surface, enhancing filtration efficiency in applications like air purifiers. Radial flow moves fluid from the center outward or vice versa, maximizing pressure uniformity and is commonly used in turbines and compressors for improved mechanical performance. The core distinction lies in flow direction impacting system design, with cross flow favoring contamination control and radial flow emphasizing pressure management.

Applications of Cross Flow Systems

Cross flow systems are widely used in water treatment, food processing, and air filtration due to their effective separation of particles and efficient fluid flow across membranes. These systems excel in applications requiring continuous filtration with high flow rates and minimal clogging, such as in microfiltration and ultrafiltration processes. Their capability to handle high solid concentrations makes them essential in biotechnology, wastewater treatment, and beverage clarification industries.

Applications of Radial Flow Designs

Radial flow designs are widely used in centrifugal compressors, gas turbines, and turbochargers due to their efficient energy transfer and compact structure. These designs excel in high pressure ratio applications and moderate flow rates, making them suitable for industrial processes such as chemical plants and HVAC systems. Radial flow compressors also dominate in refrigeration and air conditioning systems where consistent pressure performance is critical.

Efficiency Comparison: Cross Flow vs Radial Flow

Radial flow designs typically achieve higher efficiency in fluid dynamic applications due to their ability to handle larger flow rates with lower pressure loss compared to cross flow configurations. Cross flow systems often excel in heat exchange efficiency by maximizing temperature gradients and enabling better heat transfer through perpendicular fluid movement. Evaluating specific operational parameters such as flow rate, pressure drops, and thermal gradients is crucial for determining the optimal efficiency between cross flow and radial flow designs.

Advantages and Limitations of Cross Flow

Cross flow filtration offers advantages such as higher filtration efficiency due to reduced membrane fouling and the ability to handle higher suspended solids concentration, making it ideal for applications requiring continuous operation. Limitations include higher energy consumption and more complex system design compared to radial flow, which may increase operational costs and maintenance requirements. Despite these challenges, cross flow filtration provides superior performance in separating fine particles and maintaining consistent flux rates.

Pros and Cons of Radial Flow

Radial flow fans offer high efficiency and superior pressure generation, making them ideal for applications requiring stable airflow and consistent pressure, such as HVAC systems and industrial processes. Their compact design and ability to handle higher static pressures provide advantages over cross flow fans, but they tend to produce more noise and have a more complex construction, leading to increased maintenance requirements. Lower airflow uniformity compared to cross flow fans can limit their effectiveness in cooling or ventilation applications where broad air distribution is essential.

Choosing the Right Flow Type for Your Needs

Choosing the right flow type depends on the application's efficiency and pressure requirements; radial flow pumps offer high pressure capabilities ideal for high-head applications, while cross flow pumps provide gentle handling of fluids with suspended solids, suitable for wastewater treatment. Radial flow pumps achieve efficient energy transfer through a perpendicular impeller design, optimizing flow for consistent, high-pressure output. Cross flow pumps utilize a unique impeller that passes fluid across the blades, ensuring lower shear stress and better handling of abrasive or sludge-laden fluids in low to medium head situations.

Cross flow Infographic

libterm.com

libterm.com