Formative manufacturing shapes raw materials into precise components through processes like casting, molding, and forging, ensuring high-quality output for various industries. This approach optimizes material usage and enhances production efficiency, reducing waste and costs significantly. Explore the rest of the article to discover how formative manufacturing can improve your production capabilities and product quality.

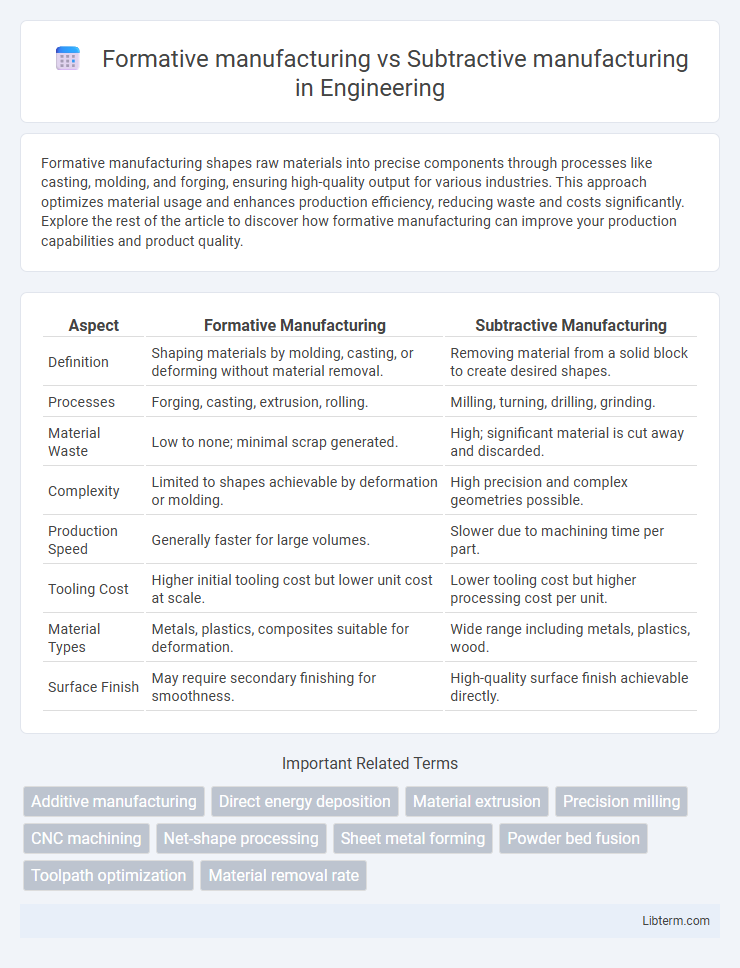

Table of Comparison

| Aspect | Formative Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Definition | Shaping materials by molding, casting, or deforming without material removal. | Removing material from a solid block to create desired shapes. |

| Processes | Forging, casting, extrusion, rolling. | Milling, turning, drilling, grinding. |

| Material Waste | Low to none; minimal scrap generated. | High; significant material is cut away and discarded. |

| Complexity | Limited to shapes achievable by deformation or molding. | High precision and complex geometries possible. |

| Production Speed | Generally faster for large volumes. | Slower due to machining time per part. |

| Tooling Cost | Higher initial tooling cost but lower unit cost at scale. | Lower tooling cost but higher processing cost per unit. |

| Material Types | Metals, plastics, composites suitable for deformation. | Wide range including metals, plastics, wood. |

| Surface Finish | May require secondary finishing for smoothness. | High-quality surface finish achievable directly. |

Introduction to Formative and Subtractive Manufacturing

Formative manufacturing involves shaping materials by deforming or molding them into the desired form, commonly used in processes such as casting, forging, and extrusion. Subtractive manufacturing removes material from a solid block through cutting, drilling, or milling to achieve precise dimensions and intricate designs, typical in CNC machining and milling operations. Both methods serve distinct purposes in production, with formative manufacturing offering faster mass production and subtractive manufacturing providing high precision and flexibility.

Defining Formative Manufacturing

Formative manufacturing involves shaping materials by deforming or molding them into the desired form, utilizing processes such as forging, rolling, extrusion, and casting. Unlike subtractive manufacturing, which removes material to achieve the final shape, formative methods alter the material's geometry without significant waste. These techniques optimize material usage and structural integrity, making them ideal for high-volume production and complex geometries.

Overview of Subtractive Manufacturing

Subtractive manufacturing involves removing material from a solid block using cutting tools such as mills, lathes, or drills to achieve the desired shape, commonly utilized in industries like aerospace and automotive for precision parts. This process allows for high accuracy and fine surface finishes but often results in significant material waste compared to formative manufacturing methods. It is essential in producing complex geometries that are difficult to achieve through additive or formative techniques.

Key Differences Between Formative and Subtractive Processes

Formative manufacturing shapes materials through deformation techniques such as casting, forging, or molding, preserving the material's integrity while minimizing waste. Subtractive manufacturing removes material by cutting, drilling, or milling from a solid block, often resulting in higher material waste but allowing precise detail and complex geometries. Key differences include material efficiency, with formative processes being more sustainable, and design flexibility, where subtractive methods provide superior accuracy and surface finish.

Common Techniques in Formative Manufacturing

Common techniques in formative manufacturing include casting, molding, and forging, where materials are shaped by deformation or shaping processes without removing material. These methods are essential for producing complex geometries and high-strength components with minimal waste. Formative manufacturing techniques contrast with subtractive processes by building parts through shaping and forming rather than cutting or machining away material.

Popular Methods in Subtractive Manufacturing

Popular methods in subtractive manufacturing include CNC machining, milling, turning, and drilling, which involve removing material from a solid block using computer-controlled tools. These techniques provide high precision and surface finish quality, making them ideal for producing complex parts from metals, plastics, and composites. CNC milling is especially prevalent in aerospace and automotive industries due to its ability to create intricate geometries with tight tolerances.

Material Suitability and Selection

Formative manufacturing excels with ductile materials like aluminum, copper, and various polymers due to its ability to shape metals through deformation processes such as forging, casting, and extrusion, preserving material integrity and reducing waste. Subtractive manufacturing is ideal for brittle materials like ceramics, composites, and hardened steels, where precision cutting, milling, or machining removes excess material to achieve complex geometries with tight tolerances. Material selection between the two depends on factors like hardness, ductility, and thermal properties, influencing the manufacturing process choice to optimize strength, durability, and cost-efficiency.

Applications and Industry Uses

Formative manufacturing, including processes such as casting, forging, and additive manufacturing, is widely used in aerospace, automotive, and medical industries for creating complex geometries and lightweight components with minimal material waste. Subtractive manufacturing, involving CNC machining and milling, is preferred in precision engineering, mold making, and prototyping sectors where high accuracy and surface finish are critical. Both methods play a crucial role in electronics, tool and die industries, with formative techniques enabling rapid production and subtractive methods providing detailed refinement and customization.

Cost, Efficiency, and Environmental Impact

Formative manufacturing typically incurs lower material costs and waste generation compared to subtractive manufacturing, which often involves higher expenses due to material removal and tooling wear. Efficiency in formative processes is enhanced by shorter production cycles and less energy consumption, while subtractive methods can be slower and more energy-intensive due to machining operations. Environmentally, formative manufacturing reduces raw material waste and emissions, promoting sustainability, whereas subtractive manufacturing tends to produce more scrap and consumes greater resources, increasing its environmental footprint.

Choosing the Right Manufacturing Method

Choosing the right manufacturing method depends on factors such as material type, production volume, and design complexity. Formative manufacturing, including processes like injection molding and forging, is ideal for high-volume production with consistent quality and minimal waste. Subtractive manufacturing, such as CNC machining and milling, excels in producing precise, low-volume components with complex geometries from solid materials.

Formative manufacturing Infographic

libterm.com

libterm.com