Shell and tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, designed to efficiently transfer heat between two fluids. Their robust construction allows for high-pressure applications and easy maintenance, making them ideal for industries like power generation, chemical processing, and oil refining. Discover how this versatile equipment can optimize your thermal systems by exploring the rest of the article.

Table of Comparison

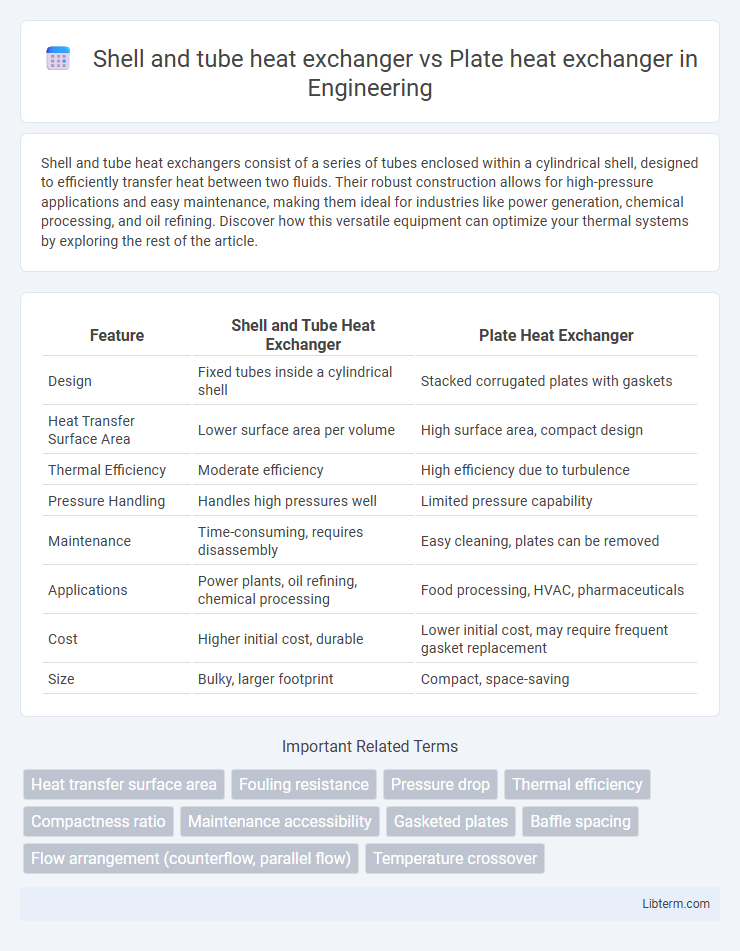

| Feature | Shell and Tube Heat Exchanger | Plate Heat Exchanger |

|---|---|---|

| Design | Fixed tubes inside a cylindrical shell | Stacked corrugated plates with gaskets |

| Heat Transfer Surface Area | Lower surface area per volume | High surface area, compact design |

| Thermal Efficiency | Moderate efficiency | High efficiency due to turbulence |

| Pressure Handling | Handles high pressures well | Limited pressure capability |

| Maintenance | Time-consuming, requires disassembly | Easy cleaning, plates can be removed |

| Applications | Power plants, oil refining, chemical processing | Food processing, HVAC, pharmaceuticals |

| Cost | Higher initial cost, durable | Lower initial cost, may require frequent gasket replacement |

| Size | Bulky, larger footprint | Compact, space-saving |

Overview of Shell and Tube vs Plate Heat Exchangers

Shell and tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, enabling the transfer of heat between two fluids through tube walls, making them suitable for high-pressure and high-temperature applications. Plate heat exchangers use corrugated metal plates stacked together to facilitate heat exchange, offering a compact design with high heat transfer efficiency and easier cleaning. Shell and tube models excel in robustness and handling large volumes, while plate heat exchangers are preferred for space-saving needs and processes requiring frequent maintenance.

Key Design Differences

Shell and tube heat exchangers feature a cylindrical shell with multiple tubes inside, designed for high-pressure and high-temperature applications with robust mechanical strength. Plate heat exchangers consist of multiple thin, corrugated plates stacked together, allowing for high heat transfer efficiency and compact size, ideal for lower pressure environments. The key design differences lie in their construction, fluid flow paths, and suitability for varying thermal and pressure conditions.

Working Principles Explained

Shell and tube heat exchangers operate by directing one fluid through a series of tubes while another fluid flows around these tubes within a sealed shell, facilitating heat transfer via conduction through tube walls. Plate heat exchangers use a series of thin, corrugated metal plates stacked together, with fluids flowing in alternating channels to maximize surface area and promote efficient heat exchange through direct contact with the plates. The key difference in working principles lies in the shell and tube design's use of concentric fluid flow paths versus the plate heat exchanger's parallel flow paths, which enhances heat transfer due to greater surface area and turbulence.

Typical Applications and Industries

Shell and tube heat exchangers are commonly used in high-pressure applications such as power plants, oil refineries, and chemical processing industries due to their robust construction and ability to handle large volumes of fluids. Plate heat exchangers find typical applications in HVAC systems, food and beverage processing, and pharmaceuticals, where efficient heat transfer and ease of cleaning are critical. Industries requiring stringent hygiene standards, such as dairy and biotechnology, often prefer plate heat exchangers for their compact design and high thermal efficiency.

Space and Footprint Considerations

Shell and tube heat exchangers typically require more space due to their bulky cylindrical design and large footprint, making them less suitable for areas with spatial constraints. Plate heat exchangers offer a compact, modular structure with a high surface area-to-volume ratio, significantly reducing installation footprint and enabling easier integration in tight spaces. Their slim profile and stacked plate arrangement optimize vertical and horizontal space usage, ideal for installations demanding minimal physical footprint.

Heat Transfer Efficiency Comparison

Shell and tube heat exchangers typically offer lower heat transfer efficiency compared to plate heat exchangers due to their larger surface area requirement and less turbulent flow. Plate heat exchangers feature a corrugated design that increases turbulence and surface area in a compact volume, enhancing heat transfer rates significantly. The enhanced turbulence in plate heat exchangers reduces fouling and improves overall heat transfer coefficients, making them more efficient in most applications.

Maintenance and Cleaning Requirements

Shell and tube heat exchangers require regular maintenance involving tube cleaning to prevent fouling and scaling, often using mechanical or chemical cleaning methods. Plate heat exchangers feature easy disassembly, allowing quick access to plates for manual cleaning or replacement, reducing downtime. Maintenance costs tend to be higher for shell and tube designs due to their complex structure and larger size compared to the compact and modular plate heat exchangers.

Cost Analysis and Investment

Shell and tube heat exchangers generally require higher initial capital investment due to their larger size, more complex fabrication, and use of heavier materials, which increases manufacturing and installation costs. Plate heat exchangers offer lower upfront costs and reduced footprint, leading to savings in both equipment purchase and facility space; however, their sealing components may incur higher maintenance expenses over time. Cost analysis should consider operational efficiency, maintenance frequency, and application-specific requirements to determine the most economically viable option for heat transfer systems.

Pressure and Temperature Capabilities

Shell and tube heat exchangers can handle high pressure and temperature applications, often exceeding 100 bar and 500degC, making them suitable for industrial processes like oil refining and power generation. Plate heat exchangers, while offering excellent heat transfer efficiency, typically operate within lower pressure ranges, generally up to 30 bar, and maximum temperatures around 180degC, limiting their use in extreme conditions. The robust construction of shell and tube designs ensures durability under severe thermal and pressure stresses compared to the gasketed or welded plates in plate heat exchangers.

Choosing the Right Heat Exchanger for Your Needs

Shell and tube heat exchangers are ideal for high-pressure and high-temperature applications, offering robust construction and easy maintenance, especially in industries like petrochemical and power generation. Plate heat exchangers provide excellent heat transfer efficiency with compact design, making them suitable for HVAC, food processing, and other applications requiring frequent cleaning and tight temperature control. Consider factors such as thermal performance, space constraints, maintenance frequency, and fluid characteristics to select the most efficient and cost-effective heat exchanger for your specific needs.

Shell and tube heat exchanger Infographic

libterm.com

libterm.com