Shear strength defines a material's ability to resist forces that cause its internal structure to slide against itself, critical in construction and engineering applications. Understanding shear strength helps ensure the stability and safety of various structures under load. Explore the full article to learn how shear strength impacts your projects and how to enhance it effectively.

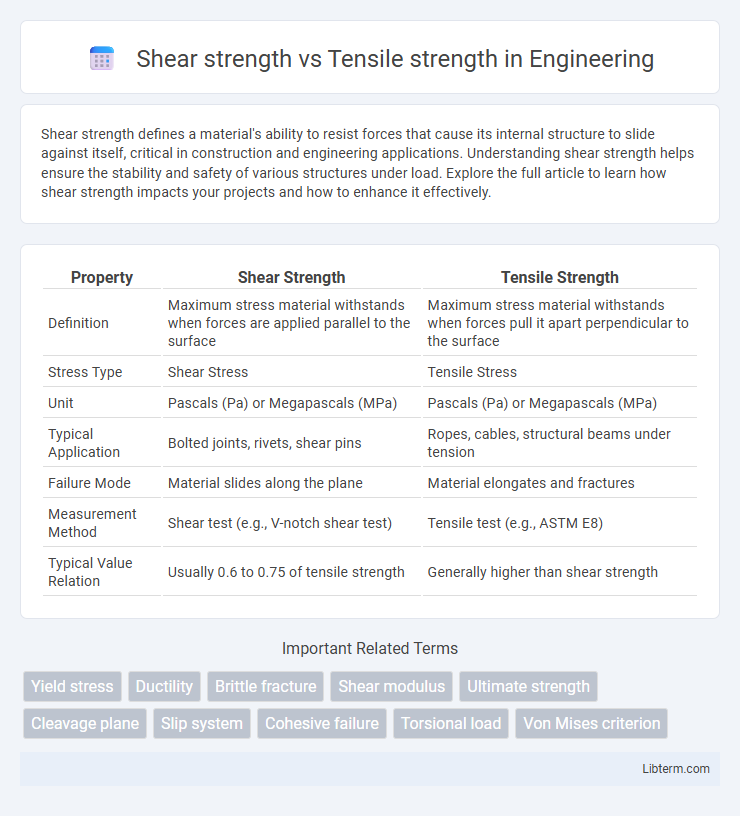

Table of Comparison

| Property | Shear Strength | Tensile Strength |

|---|---|---|

| Definition | Maximum stress material withstands when forces are applied parallel to the surface | Maximum stress material withstands when forces pull it apart perpendicular to the surface |

| Stress Type | Shear Stress | Tensile Stress |

| Unit | Pascals (Pa) or Megapascals (MPa) | Pascals (Pa) or Megapascals (MPa) |

| Typical Application | Bolted joints, rivets, shear pins | Ropes, cables, structural beams under tension |

| Failure Mode | Material slides along the plane | Material elongates and fractures |

| Measurement Method | Shear test (e.g., V-notch shear test) | Tensile test (e.g., ASTM E8) |

| Typical Value Relation | Usually 0.6 to 0.75 of tensile strength | Generally higher than shear strength |

Understanding Shear Strength and Tensile Strength

Shear strength measures a material's ability to resist forces that cause sliding or deformation along a plane, while tensile strength evaluates the resistance to forces that pull or stretch the material. Understanding shear strength is critical in applications involving cutting, punching, or any scenario where layers or components might slide past each other under load. Tensile strength provides essential data for designing structures and materials subjected to pulling or tension, ensuring durability and preventing failure under stress.

Fundamental Differences Between Shear and Tensile Strength

Shear strength measures a material's ability to resist forces that cause sliding or angular deformation along a plane, while tensile strength quantifies resistance to forces that attempt to elongate or pull the material apart. The fundamental difference lies in the direction of applied stress: shear strength is related to parallel stresses causing layers to slide, whereas tensile strength deals with normal stresses causing elongation. Materials often exhibit higher tensile strength than shear strength due to their atomic bonding structure, which resists pulling forces more effectively than sliding forces.

The Science Behind Shear Strength

Shear strength measures a material's ability to resist forces that cause its internal structure to slide parallel to the applied load, whereas tensile strength assesses resistance to forces that attempt to pull the material apart. The science behind shear strength involves the interaction of atomic bonds and the alignment of crystal planes within the material, which dictate how easily one layer can slide over another under stress. Factors such as grain size, dislocation density, and temperature significantly influence shear strength, making it critical for applications involving cutting, machining, and structural shear forces.

Exploring Tensile Strength: Definition and Importance

Tensile strength measures a material's ability to withstand pulling forces without breaking, serving as a critical parameter in engineering and construction for ensuring structural integrity. Unlike shear strength, which resists forces causing layers to slide past each other, tensile strength defines the maximum stress a material can endure when stretched. Understanding tensile strength is essential for selecting appropriate materials in applications subject to tension, such as cables, beams, and fasteners.

Factors Influencing Shear Strength

Shear strength is influenced by factors such as material composition, grain structure, and temperature, which affect its ability to resist forces parallel to its surface. Tensile strength, while related, measures resistance to forces pulling perpendicular to the surface and is less affected by directional grain orientation. Understanding these differences is crucial in applications like metal fabrication and construction where specific force resistances determine material performance.

Key Factors Affecting Tensile Strength

Tensile strength is influenced primarily by material composition, grain structure, and temperature, which determine a material's ability to resist fracture under pulling forces. Shear strength, while related, depends more on the material's ability to withstand forces applied parallel to its surface, often influenced by factors such as microstructure and bonding characteristics. Understanding the interplay of these factors is crucial for selecting materials in engineering applications where both tensile and shear loads are present.

Mechanical Testing: Shear vs. Tensile Methods

Shear strength measures a material's resistance to forces that cause sliding between layers, while tensile strength evaluates its ability to withstand pulling forces that stretch the material. Mechanical testing methods for shear strength include direct shear tests and torsion tests, often used to assess materials like metals and composites under shear loads. Tensile testing involves uniaxial tension using standardized specimens to determine properties such as ultimate tensile strength, yield strength, and elongation, providing critical data for structural and material performance analysis.

Real-World Applications and Material Selection

Shear strength and tensile strength are critical factors in material selection for engineering applications, influencing performance under different load conditions. Components such as bolts and beams require materials with high shear strength to resist sliding failure, while cables and rods need high tensile strength to withstand stretching forces. Understanding the balance between these strengths ensures optimal durability and safety in construction, automotive, and aerospace industries.

Shear Strength vs. Tensile Strength in Engineering Design

Shear strength and tensile strength are critical mechanical properties in engineering design, dictating material performance under different loading conditions. Shear strength measures a material's ability to resist forces that cause sliding or angular deformation along a plane, while tensile strength quantifies resistance to forces that attempt to stretch or elongate the material. Accurate assessment of both properties ensures structural integrity and safety in applications ranging from metal fasteners to composite materials.

Summary Table: Shear Strength vs. Tensile Strength Comparison

Shear strength measures a material's ability to resist forces that cause sliding between its internal planes, while tensile strength indicates the maximum stress a material can withstand when stretched or pulled. Typical metals exhibit tensile strengths ranging from 200 to 2500 MPa, whereas their shear strengths are approximately 60% of their tensile strength. The summary table highlights key differences, showing tensile strength values generally higher than shear strength, emphasizing the importance of selecting materials based on the type of force encountered in engineering applications.

Shear strength Infographic

libterm.com

libterm.com