Hollow core slabs are precast concrete elements with continuous voids, designed to reduce weight without sacrificing structural integrity. These slabs offer excellent load-bearing capacity, thermal insulation, and speed up construction timelines, making them ideal for floors and roofs in residential and commercial buildings. Discover how hollow core slabs can optimize your construction projects by reading the full article.

Table of Comparison

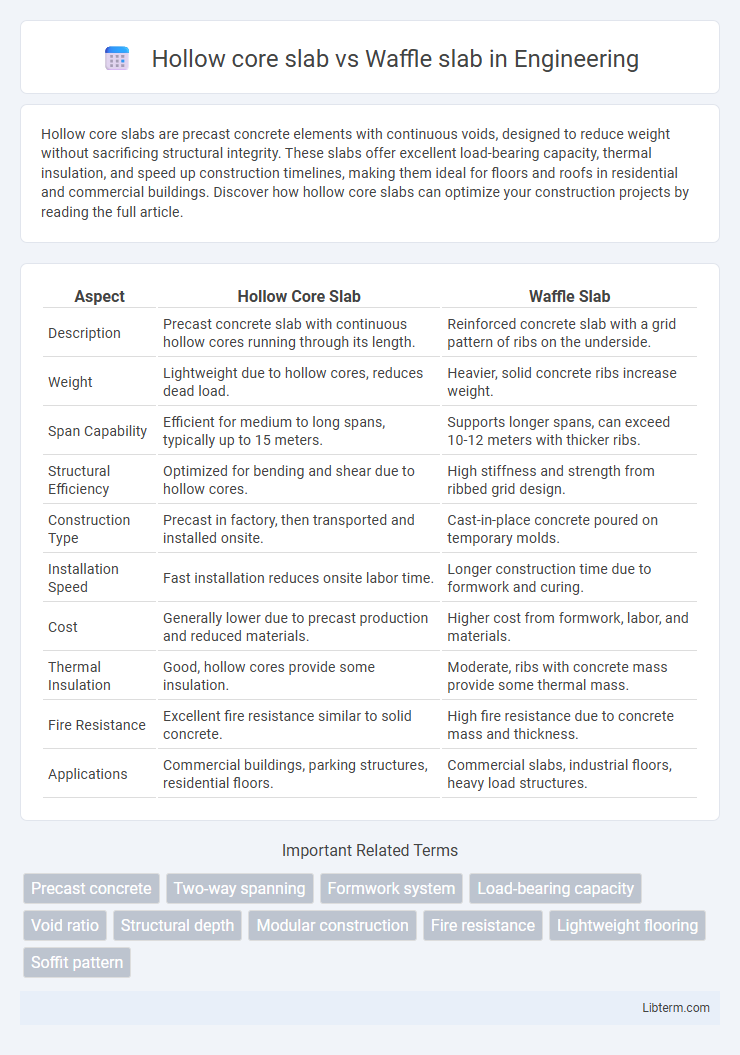

| Aspect | Hollow Core Slab | Waffle Slab |

|---|---|---|

| Description | Precast concrete slab with continuous hollow cores running through its length. | Reinforced concrete slab with a grid pattern of ribs on the underside. |

| Weight | Lightweight due to hollow cores, reduces dead load. | Heavier, solid concrete ribs increase weight. |

| Span Capability | Efficient for medium to long spans, typically up to 15 meters. | Supports longer spans, can exceed 10-12 meters with thicker ribs. |

| Structural Efficiency | Optimized for bending and shear due to hollow cores. | High stiffness and strength from ribbed grid design. |

| Construction Type | Precast in factory, then transported and installed onsite. | Cast-in-place concrete poured on temporary molds. |

| Installation Speed | Fast installation reduces onsite labor time. | Longer construction time due to formwork and curing. |

| Cost | Generally lower due to precast production and reduced materials. | Higher cost from formwork, labor, and materials. |

| Thermal Insulation | Good, hollow cores provide some insulation. | Moderate, ribs with concrete mass provide some thermal mass. |

| Fire Resistance | Excellent fire resistance similar to solid concrete. | High fire resistance due to concrete mass and thickness. |

| Applications | Commercial buildings, parking structures, residential floors. | Commercial slabs, industrial floors, heavy load structures. |

Introduction to Hollow Core Slab and Waffle Slab

Hollow core slabs are precast, prestressed concrete elements featuring continuous voids that reduce weight and material use while maintaining structural strength, making them ideal for long-span flooring systems. Waffle slabs consist of a grid of ribs beneath a thin slab, providing high load-bearing capacity and rigidity, often used in large commercial and industrial buildings. Both systems optimize material efficiency and load distribution but differ in construction methods and applications.

Structural Composition of Hollow Core Slabs

Hollow core slabs consist of precast, prestressed concrete with continuous voids running through their length, reducing weight without compromising structural strength. These voids improve load-bearing capacity and span longer distances compared to traditional solid slabs, enhancing efficiency in construction. The prestressing strands within the concrete provide tensile strength, making hollow core slabs ideal for flooring and roofing in commercial and residential buildings.

Key Features of Waffle Slabs

Waffle slabs are characterized by their grid-like pattern of ribs on the underside, providing high strength-to-weight ratio and excellent load distribution, which makes them ideal for large spans and heavy loads. These slabs consist of two-way reinforcement, allowing for greater stiffness and resistance to bending compared to hollow core slabs. The voids created between the ribs reduce dead weight while maintaining structural integrity, enhancing thermal insulation and reducing material usage.

Load-Bearing Capacity Comparison

Hollow core slabs provide high load-bearing capacity due to their pre-stressed concrete design, making them ideal for long spans in commercial and industrial buildings. Waffle slabs, featuring a grid pattern of ribs, offer superior load distribution and stiffness, effectively supporting heavy loads in large-scale structures such as parking garages and auditoriums. The structural efficiency of waffle slabs generally surpasses hollow core slabs in scenarios requiring high moment resistance and minimal deflection.

Construction Process Differences

Hollow core slabs are precast concrete elements manufactured in a controlled factory setting, allowing for rapid on-site installation by simply lifting the slabs into place using cranes, which significantly reduces construction time and labor costs. Waffle slabs require on-site formwork with a grid of beams and ribs, necessitating more extensive labor and time for assembling and casting the concrete. The hollow core slab's offsite production contrasts with the waffle slab's on-site, labor-intensive casting, impacting project scheduling and resource allocation.

Cost Analysis: Hollow Core vs Waffle Slab

Hollow core slabs typically offer lower material and labor costs due to their precast production and reduced concrete usage, making them more economical for long-span floor systems. Waffle slabs, characterized by their ribbed underside, require more complex formwork and onsite casting, leading to higher installation expenses and longer construction times. Cost analysis often favors hollow core slabs in large-scale projects where speed and budget efficiency are critical, while waffle slabs may justify the expense through enhanced structural performance and architectural flexibility.

Applications and Suitability

Hollow core slabs are ideal for residential and commercial buildings requiring long-span floors with reduced weight and increased speed of construction, especially in repetitive layouts like parking garages and schools. Waffle slabs suit structures demanding high load-bearing capacity and architectural aesthetics, such as auditoriums, hospitals, and industrial buildings with irregular column spacing. Choosing between the two depends on factors like load requirements, span lengths, architectural design, and construction timelines.

Durability and Maintenance Considerations

Hollow core slabs offer enhanced durability due to their prestressed concrete composition, which reduces cracking and improves load-bearing capacity, resulting in lower long-term maintenance costs compared to waffle slabs. Waffle slabs, characterized by a grid of ribs, can be more susceptible to water infiltration and require regular inspection to prevent deterioration of the ribs and slab surface. Maintenance of hollow core slabs typically involves periodic joint sealing and surface treatments, whereas waffle slabs demand more intensive upkeep to address potential vulnerabilities in their complex geometric structure.

Sustainability and Environmental Impact

Hollow core slabs offer superior sustainability due to their reduced concrete volume and integrated voids, which lower raw material consumption and carbon emissions during production. Waffle slabs, while structurally efficient, typically use more concrete and formwork, leading to higher embodied energy and greater environmental impact. Sustainable construction projects prioritize hollow core slabs for their ability to minimize resource use and enhance energy efficiency.

Choosing the Right Slab: Hollow Core vs Waffle

Hollow core slabs offer high structural efficiency with reduced weight and faster installation due to pre-stressed concrete voids, making them ideal for long-span floors in commercial buildings. Waffle slabs provide exceptional load-bearing capacity and architectural appeal through their grid-patterned ribbed design, suitable for heavy loads and large column spacing in institutional or industrial projects. Choosing the right slab depends on project requirements such as span length, load demands, construction speed, and architectural aesthetics, with hollow core slabs favoring cost-effective speed and waffle slabs excelling in strength and design flexibility.

Hollow core slab Infographic

libterm.com

libterm.com