Effective vibration suppression enhances the stability and longevity of machinery by minimizing oscillations and unwanted movement. Advanced materials and damping technologies are key to reducing noise and preventing structural damage. Discover how implementing these solutions can protect your equipment by exploring the full article.

Table of Comparison

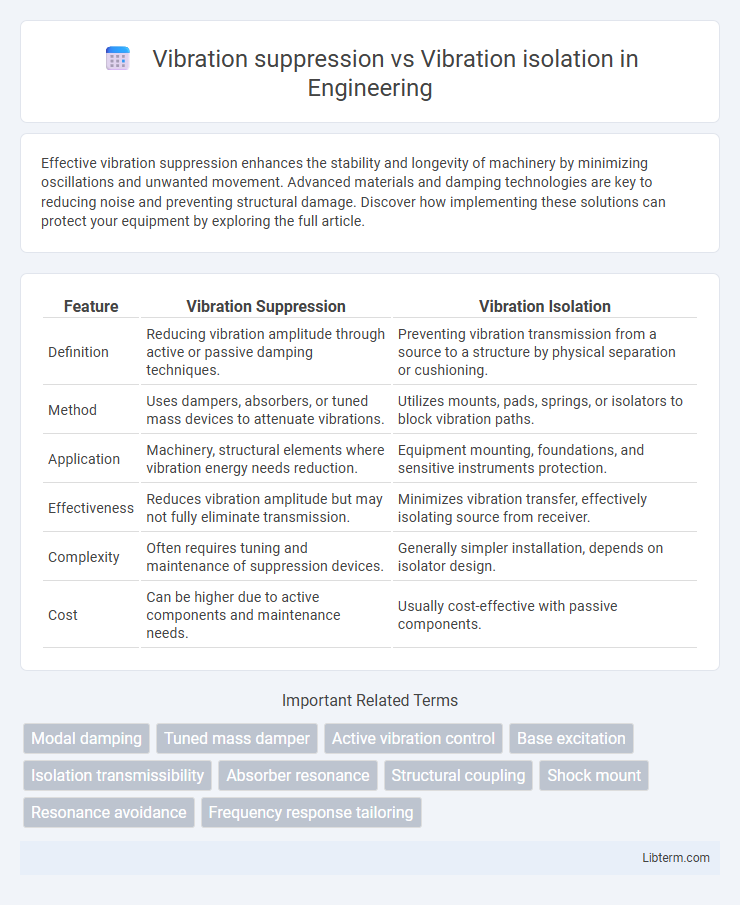

| Feature | Vibration Suppression | Vibration Isolation |

|---|---|---|

| Definition | Reducing vibration amplitude through active or passive damping techniques. | Preventing vibration transmission from a source to a structure by physical separation or cushioning. |

| Method | Uses dampers, absorbers, or tuned mass devices to attenuate vibrations. | Utilizes mounts, pads, springs, or isolators to block vibration paths. |

| Application | Machinery, structural elements where vibration energy needs reduction. | Equipment mounting, foundations, and sensitive instruments protection. |

| Effectiveness | Reduces vibration amplitude but may not fully eliminate transmission. | Minimizes vibration transfer, effectively isolating source from receiver. |

| Complexity | Often requires tuning and maintenance of suppression devices. | Generally simpler installation, depends on isolator design. |

| Cost | Can be higher due to active components and maintenance needs. | Usually cost-effective with passive components. |

Introduction to Vibration Control

Vibration suppression involves actively reducing the amplitude of vibrations through techniques such as damping, active control systems, or tuned mass dampers, effectively minimizing the energy within the vibrating structure. Vibration isolation, on the other hand, entails preventing the transmission of vibrations from a source to sensitive equipment by using isolators like springs, rubber mounts, or air cushions that absorb and block vibratory energy. Both methods are fundamental in vibration control, aiming to protect machinery, improve precision, and increase the lifespan of mechanical systems by managing undesired oscillatory motion.

Defining Vibration Suppression

Vibration suppression involves actively reducing or eliminating vibrations through the use of control systems, dampers, or absorbers to minimize the amplitude and impact of oscillations in mechanical structures. Unlike vibration isolation, which prevents vibration transmission between sources and sensitive equipment by creating physical barriers or mounts, suppression targets the vibration at its source or along its path. Effective vibration suppression enhances system stability, extends equipment lifespan, and improves performance in industries like automotive engineering and aerospace.

Understanding Vibration Isolation

Vibration isolation involves implementing physical barriers such as pads, mounts, or springs to prevent vibrations from transmitting between a source and sensitive equipment, effectively reducing possible damage or noise. This technique targets the attenuation of vibrational energy at its origin or along transmission paths, unlike vibration suppression which aims to control vibrations after they occur through active or passive damping methods. Understanding vibration isolation requires analyzing the isolation system's natural frequency, transmissibility, and the specific frequency range of the vibrations to ensure optimal separation and protection.

Key Differences Between Suppression and Isolation

Vibration suppression reduces unwanted vibrations by actively controlling or damping the vibrations once they occur, using devices such as tuned mass dampers or active control systems. Vibration isolation prevents the transmission of vibrations from the source to surrounding structures or sensitive equipment through passive means like elastomeric mounts or air springs. The key difference lies in suppression managing vibrations after they arise, while isolation blocks vibration transfer at the onset, making each technique suitable for different engineering applications.

Applications of Vibration Suppression

Vibration suppression techniques are essential in industrial machinery, automotive engineering, and aerospace applications to reduce harmful oscillations and enhance equipment longevity. Vibration suppression systems employ active or semi-active control methods, such as sensors and actuators, to counteract vibrations in real-time, improving precision in manufacturing processes and passenger comfort in vehicles. These applications prevent structural damage, reduce noise pollution, and increase operational accuracy in critical machinery.

Applications of Vibration Isolation

Vibration isolation effectively prevents transmission of unwanted vibrations to sensitive equipment, making it essential in precision manufacturing, aerospace instrumentation, and medical devices. It utilizes materials like elastomers, springs, and pneumatic mounts to absorb and dissipate vibrational energy, ensuring system stability and enhanced performance. Applications include isolating laboratory instruments, protecting electronic components in vehicles, and reducing vibrations in building foundations for seismic resilience.

Advantages of Vibration Suppression

Vibration suppression actively reduces unwanted oscillations by counteracting vibrations through sensors and actuators, offering precise control and adaptability to varying operational conditions. This approach enhances equipment lifespan and performance by minimizing wear and structural fatigue. Unlike passive vibration isolation, suppression systems provide real-time responsiveness, making them ideal for complex machinery and sensitive instruments.

Benefits of Vibration Isolation

Vibration isolation effectively reduces the transmission of vibrations from a source to sensitive equipment or structures, protecting them from potential damage and enhancing operational precision. This technique improves machinery lifespan and performance by minimizing wear and tear caused by continuous vibrations. Superior isolation systems also contribute to noise reduction, creating a safer and more comfortable working environment.

Choosing the Right Strategy: Suppression vs. Isolation

Vibration suppression targets the reduction of vibration sources through damping materials or active control systems, effectively minimizing transmission at the origin. Vibration isolation aims to prevent vibration transfer by inserting barriers like isolators or mounts between the source and sensitive equipment. Choosing the right strategy depends on factors such as vibration frequency, amplitude, system sensitivity, and environmental conditions to optimize performance and longevity.

Future Trends in Vibration Control Technologies

Future trends in vibration control technologies emphasize the integration of smart materials and adaptive systems for both vibration suppression and vibration isolation. Advanced sensors and AI-driven algorithms enable real-time monitoring and dynamic adjustment to varying vibration frequencies, enhancing performance in aerospace, automotive, and civil engineering applications. Innovations in metamaterials and active control devices promise increased efficiency and miniaturization, driving the next generation of vibration management solutions.

Vibration suppression Infographic

libterm.com

libterm.com