Traditional manufacturing relies on established processes such as casting, forging, machining, and assembly to produce goods with consistent quality and reliability. This method emphasizes precision, durability, and material efficiency, often using manual labor and mechanical tools. Explore the rest of the article to understand how traditional manufacturing shapes industries and what it means for your manufacturing needs.

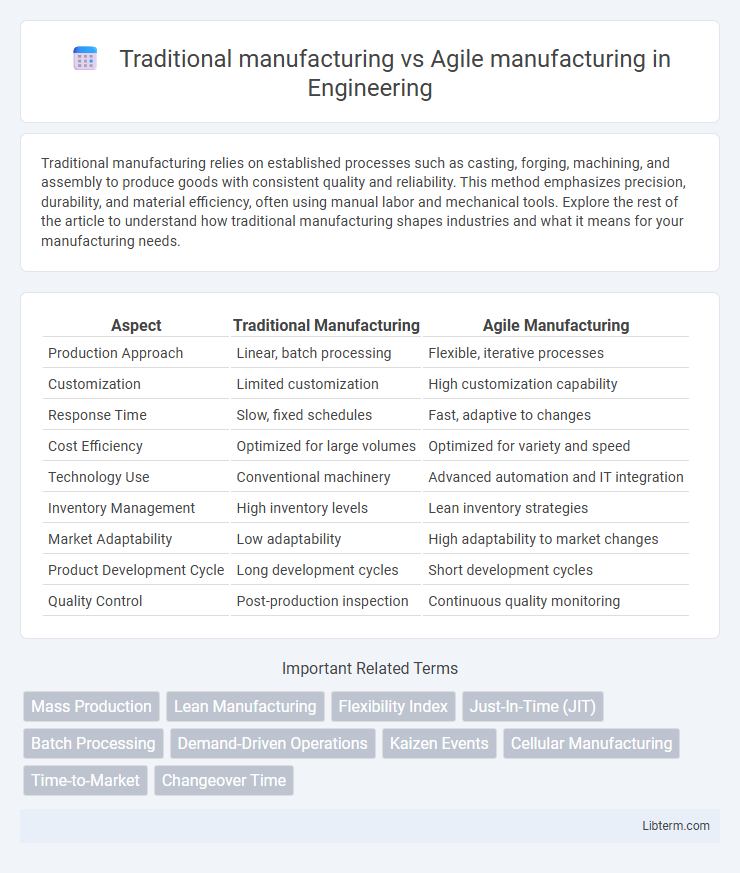

Table of Comparison

| Aspect | Traditional Manufacturing | Agile Manufacturing |

|---|---|---|

| Production Approach | Linear, batch processing | Flexible, iterative processes |

| Customization | Limited customization | High customization capability |

| Response Time | Slow, fixed schedules | Fast, adaptive to changes |

| Cost Efficiency | Optimized for large volumes | Optimized for variety and speed |

| Technology Use | Conventional machinery | Advanced automation and IT integration |

| Inventory Management | High inventory levels | Lean inventory strategies |

| Market Adaptability | Low adaptability | High adaptability to market changes |

| Product Development Cycle | Long development cycles | Short development cycles |

| Quality Control | Post-production inspection | Continuous quality monitoring |

Introduction to Manufacturing Paradigms

Traditional manufacturing relies on linear, rigid processes emphasizing mass production and standardized outputs, while Agile manufacturing prioritizes flexibility, rapid response to market changes, and customer customization. The shift from fixed production lines to adaptive systems integrates cross-functional teams and advanced technologies like IoT and AI, enhancing real-time decision-making. Understanding these paradigms is crucial for businesses aiming to balance efficiency with innovation in competitive markets.

Defining Traditional Manufacturing

Traditional manufacturing relies on well-established, linear production processes, emphasizing mass production with fixed schedules and long product development cycles. It prioritizes economies of scale, consistency, and cost minimization through standardized workflows and minimal customization. This approach often struggles with responsiveness to market changes, making it less flexible than Agile manufacturing models.

Understanding Agile Manufacturing

Agile manufacturing emphasizes flexibility and rapid response to market changes through modular processes and cross-functional teams, contrasting with traditional manufacturing's rigid, linear production lines designed for high volume and efficiency. It leverages real-time data, advanced technologies like IoT and AI, and iterative development cycles to minimize lead times and customize products. This approach enhances competitiveness by enabling manufacturers to adapt quickly to customer demands and supply chain disruptions.

Key Differences Between Traditional and Agile Approaches

Traditional manufacturing relies on rigid, sequential processes with long production cycles and fixed product designs, emphasizing efficiency and cost control through economies of scale. Agile manufacturing prioritizes flexibility, rapid iteration, and responsiveness to market changes by utilizing cross-functional teams and adaptive technologies to customize products quickly. The key difference lies in traditional methods' focus on standardization and stability versus agile's emphasis on collaboration, innovation, and speed to meet dynamic customer demands.

Flexibility and Responsiveness in Manufacturing

Traditional manufacturing relies on rigid, linear processes that prioritize efficiency and consistency but often lack flexibility to adapt quickly to market changes. Agile manufacturing emphasizes adaptable production systems and cross-functional teams, enabling rapid response to shifting customer demands and supply chain disruptions. This responsiveness allows agile manufacturers to customize products and scale operations swiftly, enhancing competitive advantage in dynamic markets.

Impact on Production Efficiency

Traditional manufacturing relies on rigid, linear processes with fixed schedules, often resulting in longer lead times and less flexibility, which can hinder production efficiency. Agile manufacturing emphasizes adaptability, rapid response to market changes, and iterative workflows, leading to reduced waste and faster turnaround times. Implementing agile methodologies typically improves overall production efficiency by enabling real-time adjustments and continuous process optimization.

Cost Implications: Traditional vs Agile

Traditional manufacturing often incurs higher upfront costs due to extensive planning, large batch production, and inflexible supply chains, resulting in increased inventory holding and waste expenses. Agile manufacturing reduces costs by emphasizing flexibility, smaller production runs, and rapid response to market changes, which minimizes inventory and accelerates cash flow. Cost efficiency in agile systems is driven by just-in-time inventory management and continuous process improvements, contrasting with the fixed overhead and slower adaptation costs in traditional setups.

Quality Control and Product Customization

Traditional manufacturing emphasizes rigorous quality control through standardized processes and fixed specifications, ensuring consistent product quality but limited flexibility for customization. Agile manufacturing integrates real-time quality control with adaptive processes, enabling rapid adjustments to meet specific customer requirements while maintaining high standards. This approach enhances product personalization without compromising quality, leveraging advanced technologies like IoT and AI-driven analytics for continuous monitoring.

Technological Integration and Innovation

Traditional manufacturing relies heavily on legacy systems with limited technological integration, resulting in slower innovation cycles and less flexibility. Agile manufacturing emphasizes advanced digital technologies, such as IoT, AI, and real-time data analytics, to enhance responsiveness and streamline production processes. This robust technological integration fuels continuous innovation, enabling rapid adaptation to market demands and customization.

Choosing the Right Approach for Your Business

Traditional manufacturing emphasizes standardized processes and long production cycles, ideal for high-volume, low-variation products seeking cost efficiency. Agile manufacturing prioritizes flexibility and rapid response to market changes, suitable for businesses requiring customization and quick product iterations. Selecting the right approach depends on factors like product complexity, customer demand variability, and the need for speed versus cost control.

Traditional manufacturing Infographic

libterm.com

libterm.com