Chain drive systems efficiently transmit mechanical power between rotating shafts using linked metal chains and sprockets. They provide reliable performance in various applications, from bicycles to industrial machinery, due to their durability and ability to handle high torque loads. Discover how understanding chain drive components and maintenance can enhance your equipment's performance by reading the full article.

Table of Comparison

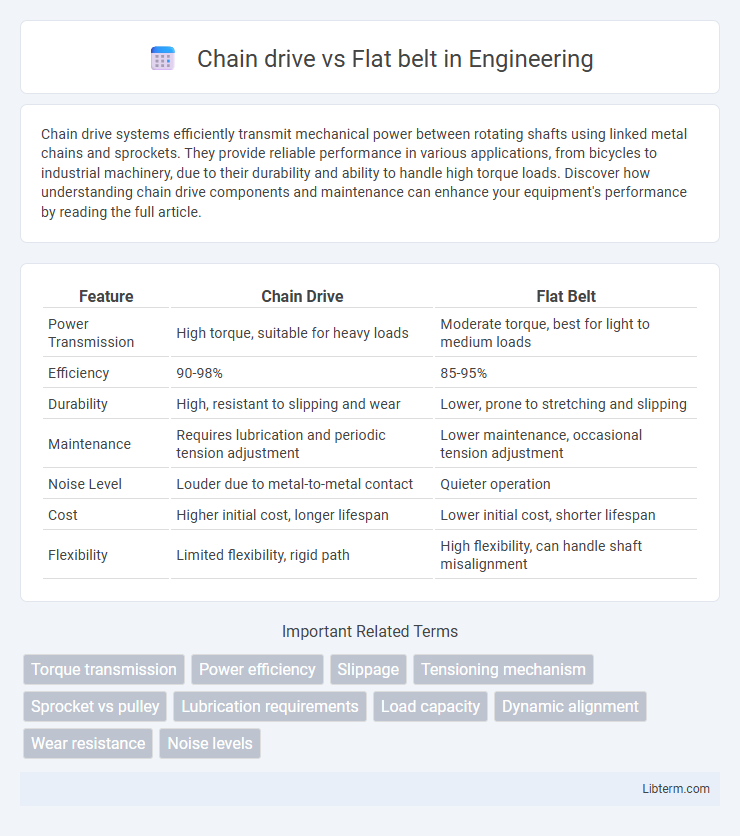

| Feature | Chain Drive | Flat Belt |

|---|---|---|

| Power Transmission | High torque, suitable for heavy loads | Moderate torque, best for light to medium loads |

| Efficiency | 90-98% | 85-95% |

| Durability | High, resistant to slipping and wear | Lower, prone to stretching and slipping |

| Maintenance | Requires lubrication and periodic tension adjustment | Lower maintenance, occasional tension adjustment |

| Noise Level | Louder due to metal-to-metal contact | Quieter operation |

| Cost | Higher initial cost, longer lifespan | Lower initial cost, shorter lifespan |

| Flexibility | Limited flexibility, rigid path | High flexibility, can handle shaft misalignment |

Introduction to Chain Drives and Flat Belts

Chain drives use interlocking metal links to transmit power between sprockets, offering high strength and efficient torque transfer in machinery. Flat belts consist of flexible, flat materials like leather or fabric running over pulleys, providing smooth, quiet operation and adjustable speed control. Both systems serve distinct industrial purposes, with chain drives favored for heavy loads and flat belts for lighter, variable-speed applications.

Key Components and Design Overview

Chain drives consist of interconnected metal links forming a robust loop that engages with sprockets, providing high torque transmission and durability in heavy-duty applications. Flat belts are made from flexible materials like rubber or leather, running over smooth pulleys to deliver quieter, smoother motion suitable for moderate power transfer and long-distance drives. Chain drives require precision sprocket alignment and tensioners for optimal performance, while flat belt systems depend on pulley surface friction and tensioning mechanisms to prevent slippage and maintain efficient power transfer.

Power Transmission Efficiency

Chain drives typically offer higher power transmission efficiency, ranging between 95% to 98%, due to their direct mechanical engagement and minimal slip. Flat belts generally have lower efficiency, around 90% to 95%, because of belt slip and stretching over time. The choice between chain drive and flat belt systems depends on factors like load capacity, maintenance requirements, and operating speed.

Maintenance Requirements

Chain drives require regular lubrication and tension adjustments to prevent wear and elongation, with periodic inspections for rust and damaged links crucial for maintaining efficiency. Flat belts demand frequent alignment checks and tension adjustments to avoid slipping and uneven wear, along with monitoring for cracks or fraying on the belt surface. Both systems benefit from consistent cleaning to remove debris, but chain drives typically involve more intensive maintenance due to their mechanical complexity and exposure to dirt and moisture.

Durability and Lifespan

Chain drives typically offer superior durability and lifespan compared to flat belts due to their robust metal construction, which resists stretching and slipping under heavy loads. Flat belts, often made from rubber or synthetic materials, tend to wear out faster and require frequent adjustments or replacements in high-tension or abrasive environments. Maintenance requirements for chain drives include lubrication and occasional tensioning, but their longevity under continuous operation generally surpasses that of flat belts, making them ideal for demanding industrial applications.

Operational Speed Capabilities

Chain drives excel in high operational speed capabilities due to their rigid interlocking links, enabling efficient power transmission at speeds often exceeding 10,000 RPM in industrial applications. Flat belts, while quieter and less expensive, typically perform best at moderate speeds ranging from 500 to 4,000 RPM, as higher speeds increase the risk of slippage and belt wear. The choice between chain drives and flat belts hinges on the required speed, with chains favored for high-speed, high-torque scenarios and flat belts suited for lower-speed, lighter-load operations.

Noise and Vibration Considerations

Chain drives typically generate higher noise levels and vibration due to the metal-on-metal contact and the engagement of chain links with sprockets, which can lead to increased wear and mechanical stress. Flat belts, made of flexible materials like rubber or leather, offer quieter operation and reduced vibration because they absorb shock and provide smoother power transmission. Choosing between chain drives and flat belts depends on the application's noise sensitivity and vibration tolerance requirements.

Cost Comparison

Chain drives typically entail higher initial costs due to the use of durable materials and precise manufacturing, but offer longer service life with minimal maintenance. Flat belts present lower upfront expenses and simpler installation but may require frequent adjustments and replacements, increasing long-term operational costs. Overall, chain drives prove cost-effective for high-load applications, while flat belts suit lighter-duty systems with budget constraints.

Applications and Industry Usage

Chain drives are widely used in heavy machinery, automotive engines, and industrial conveyors due to their high torque transmission and durability under harsh conditions. Flat belts find application in light to medium power transmission, such as in textile machines, agricultural equipment, and small-scale manufacturing, offering smooth and quiet operation. Industries like automotive manufacturing, agriculture, and material handling predominantly favor chain drives for robustness, while flat belts are preferred in textile and packaging sectors for flexibility and cost-effectiveness.

Choosing the Right System for Your Needs

Chain drives offer high torque transmission and durability, making them ideal for heavy-duty applications requiring precise speed ratios and minimal slippage. Flat belts provide quieter operation and easier maintenance, suitable for lighter loads and flexible speed adjustments in low to medium power settings. Assess factors like load capacity, environmental conditions, and maintenance demands to determine the best drive system for your operational requirements.

Chain drive Infographic

libterm.com

libterm.com