Brittleness refers to a material's tendency to fracture or break without significant deformation when subjected to stress. Understanding brittleness is crucial for selecting materials that ensure safety and durability in construction, manufacturing, and product design. Explore the rest of the article to learn how brittleness impacts your material choices and performance outcomes.

Table of Comparison

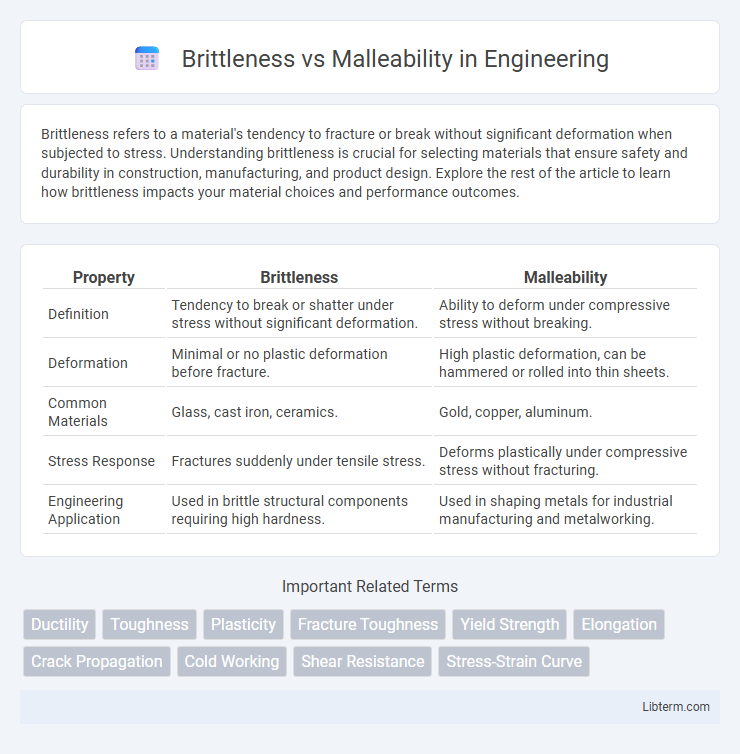

| Property | Brittleness | Malleability |

|---|---|---|

| Definition | Tendency to break or shatter under stress without significant deformation. | Ability to deform under compressive stress without breaking. |

| Deformation | Minimal or no plastic deformation before fracture. | High plastic deformation, can be hammered or rolled into thin sheets. |

| Common Materials | Glass, cast iron, ceramics. | Gold, copper, aluminum. |

| Stress Response | Fractures suddenly under tensile stress. | Deforms plastically under compressive stress without fracturing. |

| Engineering Application | Used in brittle structural components requiring high hardness. | Used in shaping metals for industrial manufacturing and metalworking. |

Introduction to Brittleness and Malleability

Brittleness refers to a material's tendency to fracture or break without significant deformation when subjected to stress, commonly observed in ceramics and glass. Malleability is the ability of a material, such as gold or aluminum, to deform under compressive stress without cracking, allowing it to be shaped into thin sheets. Understanding the distinction between brittleness and malleability is crucial for selecting appropriate materials in engineering and manufacturing applications.

Defining Brittleness: Meaning and Characteristics

Brittleness is a material property characterized by the tendency to fracture or break without significant deformation when subjected to stress. Materials like glass and ceramics exhibit brittleness due to their atomic structure, which limits dislocation movement and energy absorption. This property contrasts sharply with malleability, where materials deform plastically under stress instead of fracturing.

Understanding Malleability: Key Features

Malleability refers to a material's ability to deform under compressive stress, allowing it to be hammered or rolled into thin sheets without breaking. Metals like gold, silver, and copper exhibit high malleability due to their atomic structure, where atoms can slide past each other without fracturing. This property is crucial in manufacturing processes such as forging, embossing, and sheet metal fabrication.

Atomic Structure and Bonding Differences

Brittleness arises in materials with ionic or covalent bonding where atoms are tightly bonded in a fixed lattice, restricting atomic movement and causing fracture under stress. Malleability is characteristic of metallic bonds, where positively charged ions are surrounded by a sea of delocalized electrons allowing atoms to slide past one another without breaking. The atomic structure in brittle materials features directional bonds limiting dislocation motion, whereas malleable materials possess non-directional metallic bonds enabling plastic deformation.

Common Materials: Brittle vs Malleable Examples

Glass and ceramics are common examples of brittle materials, characterized by their inability to deform plastically and tendency to fracture under stress. Metals like gold, copper, and aluminum demonstrate malleability, allowing them to be hammered or rolled into thin sheets without breaking. Understanding the brittleness of concrete compared to the malleability of steel highlights the practical implications of these material properties in construction and manufacturing.

Mechanical Properties Comparison

Brittleness describes a material's tendency to fracture without significant deformation under stress, characterized by low toughness and minimal plastic strain before failure. Malleability refers to a material's ability to undergo extensive plastic deformation without cracking, allowing it to be shaped or hammered into thin sheets. Comparing mechanical properties, brittle materials exhibit high strength but low ductility, while malleable materials show lower strength with high ductility and energy absorption capacity.

Factors Affecting Brittleness and Malleability

Brittleness and malleability in materials are primarily influenced by their atomic structure, bonding type, and temperature conditions. Metals with metallic bonding and closely packed crystal structures exhibit high malleability due to mobile dislocations, while ionic or covalent bonds increase brittleness by restricting atomic movement. Temperature changes affect atomic vibrations; increased heat generally enhances malleability by allowing atoms to slide past each other more easily, whereas low temperatures tend to increase brittleness by limiting atomic displacement.

Applications in Industry and Everyday Life

Brittleness in materials like glass and ceramics limits their use in applications requiring impact resistance, such as automotive windshields and electronic device screens. Malleability, exhibited by metals like copper and aluminum, enables shaping and forming in industries including construction, aerospace, and packaging. Everyday items such as kitchen foil and electrical wiring rely on malleable metals for durability and flexibility.

Testing Methods for Brittleness and Malleability

Testing methods for brittleness include fracture toughness tests and impact tests such as the Charpy and Izod tests, which evaluate a material's resistance to crack propagation and sudden failure under stress. Malleability is commonly assessed through tensile tests and ductility measurements, focusing on a material's ability to undergo plastic deformation without breaking. These testing methods provide critical insights into material properties essential for selecting appropriate metals in manufacturing and engineering applications.

Conclusion: Choosing Materials Based on Properties

Selecting materials hinges on understanding their brittleness and malleability, as brittle materials fracture under stress while malleable materials deform without breaking. Applications requiring shock resistance benefit from malleable metals like copper and aluminum, whereas brittle materials such as glass are suitable for rigid, load-bearing components. Engineers optimize product performance by matching material properties to functional requirements, balancing strength, ductility, and durability.

Brittleness Infographic

libterm.com

libterm.com