Robotic welding enhances precision and efficiency in manufacturing by automating repetitive tasks and reducing human error. This technology improves production speed while maintaining consistent weld quality, making it ideal for industries requiring high-volume output. Explore the rest of the article to discover how robotic welding can transform Your operations and boost productivity.

Table of Comparison

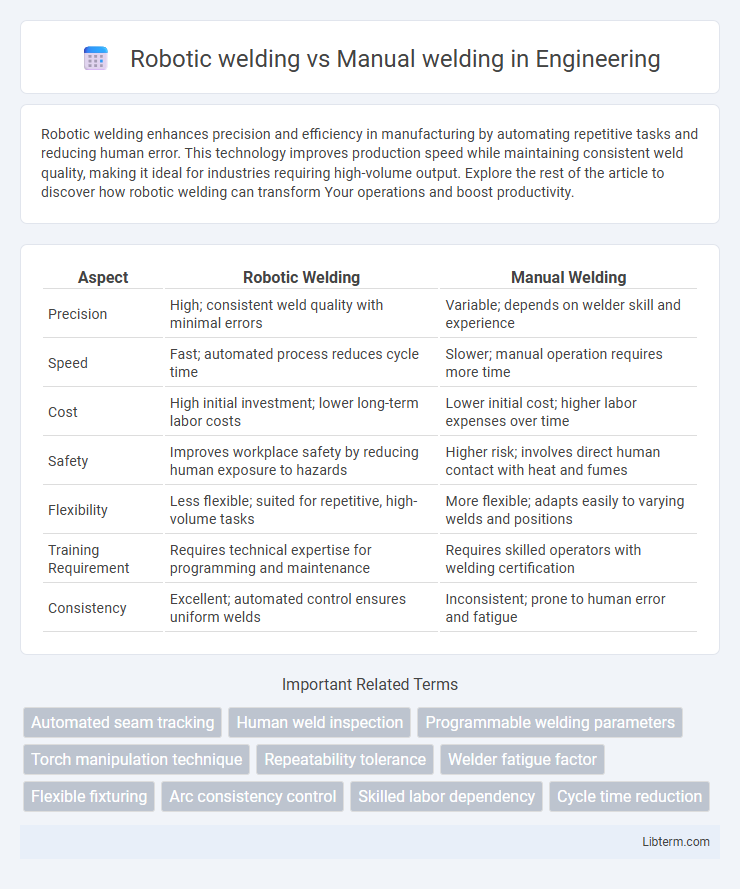

| Aspect | Robotic Welding | Manual Welding |

|---|---|---|

| Precision | High; consistent weld quality with minimal errors | Variable; depends on welder skill and experience |

| Speed | Fast; automated process reduces cycle time | Slower; manual operation requires more time |

| Cost | High initial investment; lower long-term labor costs | Lower initial cost; higher labor expenses over time |

| Safety | Improves workplace safety by reducing human exposure to hazards | Higher risk; involves direct human contact with heat and fumes |

| Flexibility | Less flexible; suited for repetitive, high-volume tasks | More flexible; adapts easily to varying welds and positions |

| Training Requirement | Requires technical expertise for programming and maintenance | Requires skilled operators with welding certification |

| Consistency | Excellent; automated control ensures uniform welds | Inconsistent; prone to human error and fatigue |

Introduction to Robotic and Manual Welding

Robotic welding employs automated machines programmed to perform precise, repetitive welding tasks, significantly enhancing production speed and consistency in manufacturing industries. Manual welding relies on skilled welders using handheld tools, offering greater flexibility and adaptability for complex or custom projects. Both techniques serve essential roles, with robotic welding excelling in high-volume applications and manual welding preferred for intricate or low-volume work.

Overview of Welding Technologies

Robotic welding utilizes automated systems equipped with programmable robots to perform precise and consistent welds, significantly enhancing efficiency and repeatability in industrial applications. Manual welding relies on skilled operators to control welding tools directly, offering flexibility for complex or customized tasks but often resulting in variable quality and slower production rates. Advances in robotic welding technologies, including sensor integration and AI-driven controls, continue to outperform manual methods in terms of speed, accuracy, and safety across various sectors such as automotive and aerospace manufacturing.

How Robotic Welding Works

Robotic welding uses automated machines programmed to perform precise welding tasks by controlling the movement of welding torches and feed materials with high accuracy and consistency. Sensors and vision systems enable real-time adjustments to welding parameters, ensuring optimal weld quality and reducing defects compared to manual welding. This technology increases production speed and repeatability while minimizing human error and exposure to hazardous environments.

Manual Welding Processes Explained

Manual welding involves the operator directly controlling the welding process, utilizing techniques such as Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Gas Tungsten Arc Welding (GTAW). This process requires skilled welders to manage heat input, electrode manipulation, and joint alignment to ensure weld quality. Despite being labor-intensive, manual welding offers flexibility for complex geometries and makes on-the-spot adjustments possible that robotic welding systems may lack.

Efficiency: Robotic vs Manual Welding

Robotic welding delivers significantly higher efficiency compared to manual welding by ensuring consistent weld quality at faster speeds with minimal downtime. Automated systems reduce human error, enabling continuous operation and increasing throughput in high-volume manufacturing environments. Manual welding, while flexible for complex or small-scale tasks, typically involves slower production rates and increased labor costs due to operator fatigue and skill variability.

Cost Comparison: Automation vs Skilled Labor

Robotic welding requires a significant initial investment in automation technology, but it reduces long-term labor costs by increasing production speed and minimizing errors. Manual welding demands skilled labor, which incurs higher wages and potential variability in quality, leading to increased rework expenses. Over time, automation delivers more consistent output and lower operational costs despite higher upfront capital.

Quality and Consistency in Welds

Robotic welding offers superior quality and consistency in welds due to its precise control over parameters such as speed, angle, and heat input, minimizing human error and variability. Manual welding can result in inconsistent weld quality because it depends heavily on the skill, experience, and fatigue level of the welder. Automated robotic systems ensure repeatable welds with uniform penetration and minimal defects, enhancing overall production reliability in high-volume manufacturing environments.

Safety Considerations in Welding Methods

Robotic welding significantly reduces the risk of exposure to hazardous fumes, intense UV radiation, and high temperatures by automating the welding process within enclosed or ventilated environments, enhancing operator safety. Manual welding exposes workers directly to harmful emissions and physical hazards such as burns and electric shock, requiring extensive personal protective equipment (PPE) and strict safety protocols. Implementing robotic welding systems decreases workplace injuries and improves compliance with occupational safety standards set by organizations like OSHA.

Applications and Industry Suitability

Robotic welding offers high precision and consistency, making it ideal for mass production in automotive, aerospace, and heavy machinery industries where repetitive tasks demand uniform weld quality. Manual welding remains preferred in construction, shipbuilding, and repair work due to its flexibility in handling complex geometries and on-site adjustments. Industries requiring scalability and strong quality control favor robotic welding, whereas sectors prioritizing customization and intricate welds rely on skilled manual welders.

Future Trends in Welding Technology

Robotic welding is increasingly dominating the future of welding technology due to its precision, speed, and ability to integrate artificial intelligence for adaptive control and quality assurance. Advanced sensors and machine learning algorithms enable robotic systems to perform complex welds with minimal human intervention, drastically reducing errors and improving productivity. Manual welding remains essential for specialized tasks and small-scale projects but is gradually being supplemented by collaborative robots that enhance human efficiency and safety on welding floors.

Robotic welding Infographic

libterm.com

libterm.com