Experimental methods involve systematic procedures designed to test hypotheses through controlled observations and measurements. These techniques allow researchers to precisely manipulate variables and analyze outcomes to validate scientific theories or discover new insights. Explore the rest of the article to understand how experimental methods can enhance your research accuracy and reliability.

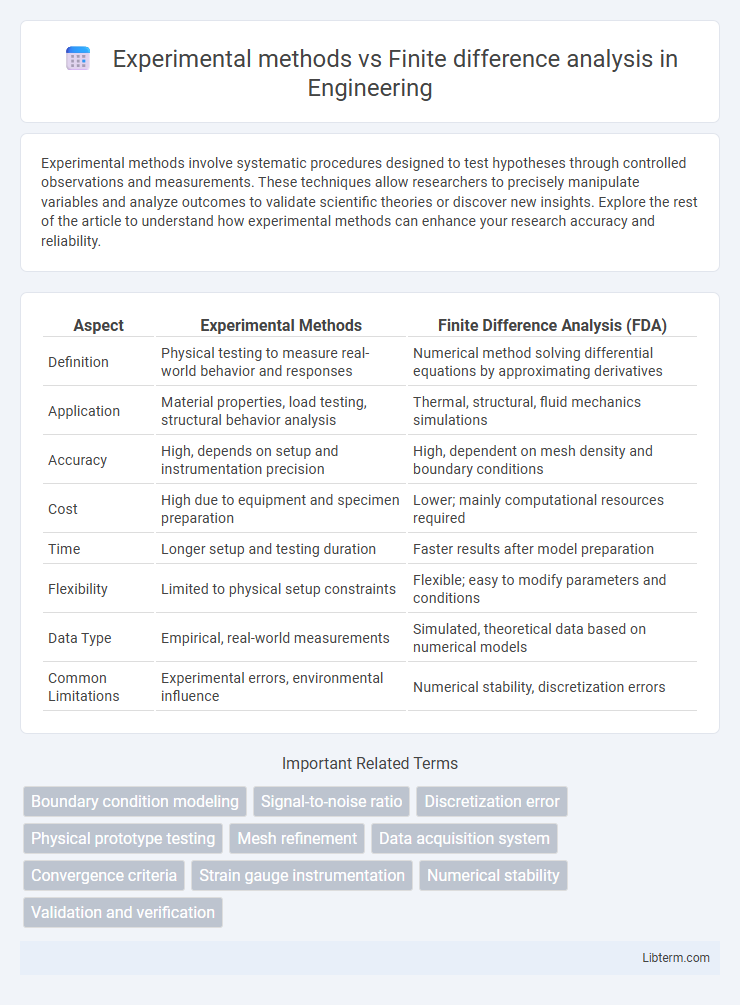

Table of Comparison

| Aspect | Experimental Methods | Finite Difference Analysis (FDA) |

|---|---|---|

| Definition | Physical testing to measure real-world behavior and responses | Numerical method solving differential equations by approximating derivatives |

| Application | Material properties, load testing, structural behavior analysis | Thermal, structural, fluid mechanics simulations |

| Accuracy | High, depends on setup and instrumentation precision | High, dependent on mesh density and boundary conditions |

| Cost | High due to equipment and specimen preparation | Lower; mainly computational resources required |

| Time | Longer setup and testing duration | Faster results after model preparation |

| Flexibility | Limited to physical setup constraints | Flexible; easy to modify parameters and conditions |

| Data Type | Empirical, real-world measurements | Simulated, theoretical data based on numerical models |

| Common Limitations | Experimental errors, environmental influence | Numerical stability, discretization errors |

Introduction to Experimental Methods and Finite Difference Analysis

Experimental methods provide direct measurement and observation of physical phenomena, enabling the validation of theoretical models through controlled testing. Finite difference analysis employs numerical techniques to approximate solutions of differential equations by discretizing continuous variables, offering efficient simulation of complex systems. Both approaches complement each other, with experimental methods ensuring accuracy and finite difference analysis enabling extensive parametric studies.

Fundamental Principles of Experimental Methods

Experimental methods rely on direct measurement and observation to capture real-world physical behaviors, providing empirical data essential for validating theoretical models. These methods are grounded in fundamental principles such as controlled variable manipulation, repeatability, and precise instrumentation to ensure accuracy and reliability. In contrast, finite difference analysis uses numerical approximations of differential equations, emphasizing computational models rather than physical testing.

Core Concepts behind Finite Difference Analysis

Finite Difference Analysis is a numerical technique used to approximate solutions to differential equations by discretizing the continuous domain into a grid and replacing derivatives with finite difference equations. Core concepts involve the use of forward, backward, or central difference schemes to estimate derivatives, stability criteria to ensure convergence, and error analysis to quantify approximation accuracy. Unlike experimental methods that rely on physical testing, finite difference analysis enables simulation of complex systems such as heat transfer or fluid flow through computational models.

Instrumentation and Data Collection in Experiments

Experimental methods rely heavily on precise instrumentation such as strain gauges, accelerometers, and pressure sensors to capture real-time data on physical phenomena, ensuring accuracy and reliability. Data collection in experiments involves direct measurement under controlled conditions, allowing observation of material behavior, stress distribution, and dynamic responses that finite difference analysis approximates numerically. Unlike finite difference analysis, which depends on mathematical discretization and boundary conditions, experimental data provides empirical validation for computational models and enhances the understanding of complex system behaviors.

Numerical Modeling and Computation in Finite Differences

Experimental methods provide empirical data by physically testing prototypes under controlled conditions, essential for validating numerical models. Finite difference analysis leverages numerical modeling to approximate solutions of differential equations by discretizing continuous variables into finite grid points. This computational approach enables efficient simulation of complex systems, offering high-resolution insights into behaviors where experimental testing may be impractical or cost-prohibitive.

Advantages and Limitations of Experimental Methods

Experimental methods offer direct observation and measurement of physical phenomena, providing highly accurate and reliable data for validating theoretical models. These methods, however, can be costly, time-consuming, and sometimes impractical for complex or large-scale systems, limiting their applicability. The necessity for specialized equipment and controlled environments also restricts the scope and repeatability of experimental investigations compared to finite difference analysis.

Pros and Cons of Finite Difference Analysis

Finite difference analysis provides a numerical approach to solving differential equations, enabling precise approximations of complex physical phenomena such as heat transfer or fluid dynamics, which experimental methods might struggle to measure directly. Its pros include cost-effectiveness, rapid simulation of multiple scenarios, and the ability to model systems under varying boundary conditions without physical prototypes. However, finite difference analysis can suffer from numerical instability, discretization errors, and requires careful mesh design to ensure accuracy, whereas experimental methods offer real-world data but at higher expense and longer setup times.

Accuracy and Validation: Comparing Both Approaches

Experimental methods provide direct measurements from physical models, offering high accuracy for complex real-world phenomena but may be limited by measurement errors and environmental variability. Finite difference analysis relies on numerical approximations of differential equations, enabling detailed examination of systems with adjustable resolution; its accuracy depends on grid size, stability criteria, and boundary conditions. Validation of finite difference results often requires experimental data to ensure reliability, making a combined approach essential for robust and precise analysis in engineering and scientific research.

Applications in Engineering and Science

Experimental methods provide direct measurement of physical phenomena, essential for validating theoretical models and capturing complex behaviors in engineering structures and scientific processes. Finite difference analysis offers computational solutions to differential equations, enabling efficient simulation of heat transfer, fluid dynamics, and stress analysis in systems where experimental testing is costly or impractical. Combining experimental data with finite difference models enhances accuracy and predictive capabilities in fields such as aerospace engineering, civil infrastructure, and environmental sciences.

Choosing the Right Approach: Key Considerations

Experimental methods provide direct physical data through controlled testing, offering high accuracy for validating real-world behavior of materials and structures. Finite difference analysis uses numerical approximations to solve complex differential equations, enabling efficient simulation of systems under various conditions without the need for physical prototypes. Key considerations for choosing between these approaches include the complexity of the problem, available resources, required accuracy, and the feasibility of physical testing versus computational modeling.

Experimental methods Infographic

libterm.com

libterm.com