Reliability Centered Maintenance (RCM) optimizes asset management by prioritizing maintenance tasks based on reliability and criticality, reducing downtime and operational costs. This approach enhances equipment performance through data-driven decision-making and risk assessment. Discover how RCM can transform your maintenance strategy by exploring the key principles and practical applications in this article.

Table of Comparison

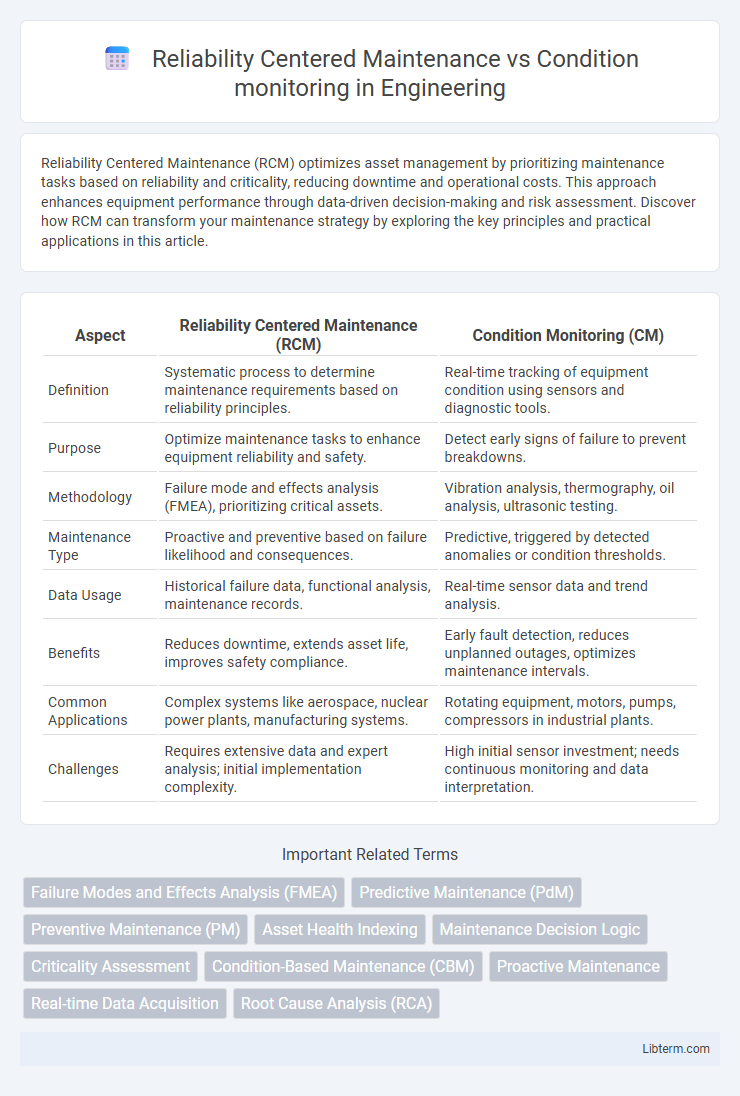

| Aspect | Reliability Centered Maintenance (RCM) | Condition Monitoring (CM) |

|---|---|---|

| Definition | Systematic process to determine maintenance requirements based on reliability principles. | Real-time tracking of equipment condition using sensors and diagnostic tools. |

| Purpose | Optimize maintenance tasks to enhance equipment reliability and safety. | Detect early signs of failure to prevent breakdowns. |

| Methodology | Failure mode and effects analysis (FMEA), prioritizing critical assets. | Vibration analysis, thermography, oil analysis, ultrasonic testing. |

| Maintenance Type | Proactive and preventive based on failure likelihood and consequences. | Predictive, triggered by detected anomalies or condition thresholds. |

| Data Usage | Historical failure data, functional analysis, maintenance records. | Real-time sensor data and trend analysis. |

| Benefits | Reduces downtime, extends asset life, improves safety compliance. | Early fault detection, reduces unplanned outages, optimizes maintenance intervals. |

| Common Applications | Complex systems like aerospace, nuclear power plants, manufacturing systems. | Rotating equipment, motors, pumps, compressors in industrial plants. |

| Challenges | Requires extensive data and expert analysis; initial implementation complexity. | High initial sensor investment; needs continuous monitoring and data interpretation. |

Understanding Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance (RCM) is a systematic approach that prioritizes maintenance tasks based on the reliability and criticality of equipment to improve operational efficiency and reduce failures. It involves identifying functions, potential failures, and appropriate maintenance strategies tailored to ensure asset reliability and safety. Unlike Condition Monitoring, which relies on real-time data to detect equipment deterioration, RCM provides a comprehensive framework integrating various maintenance methods to optimize asset performance and lifecycle costs.

Defining Condition Monitoring in Maintenance

Condition monitoring in maintenance involves the continuous or periodic measurement of equipment parameters such as vibration, temperature, and oil quality to detect early signs of wear or failure. This predictive approach enables maintenance teams to address issues before they escalate into costly breakdowns, enhancing equipment reliability and extending asset life. Unlike Reliability Centered Maintenance, which develops a maintenance strategy based on failure modes and consequences, condition monitoring focuses specifically on real-time data to inform timely interventions.

Key Principles of RCM and Condition Monitoring

Reliability Centered Maintenance (RCM) prioritizes maintaining system functions by identifying critical failures and applying appropriate maintenance strategies based on failure modes, effects analysis, and risk assessment. Condition Monitoring relies on real-time data collection through techniques like vibration analysis, thermography, and oil analysis to detect early signs of equipment degradation for predictive maintenance. Both approaches emphasize proactive asset management, yet RCM focuses on systematic process-driven decision-making while Condition Monitoring centers on continuous performance data evaluation.

Goals and Objectives: RCM vs Condition Monitoring

Reliability Centered Maintenance (RCM) aims to identify and prioritize maintenance activities based on the criticality of equipment and its failure modes to ensure operational reliability and safety. Condition Monitoring focuses on real-time data acquisition and analysis of equipment health indicators such as vibration, temperature, and oil quality to detect and prevent failures before they occur. While RCM establishes a strategic framework for optimized maintenance planning, Condition Monitoring provides tactical, data-driven insights to support proactive maintenance decisions.

Methodologies: Proactive vs Reactive Approaches

Reliability Centered Maintenance (RCM) employs a proactive approach by systematically analyzing equipment functions and potential failure modes to develop tailored maintenance strategies that prevent breakdowns. In contrast, Condition Monitoring is generally reactive, relying on real-time data from sensors and diagnostic tools to detect abnormalities and trigger maintenance actions when performance deviates from established thresholds. While RCM focuses on preemptive planning to optimize reliability and minimize downtime, Condition Monitoring emphasizes continuous observation to react promptly to emerging equipment issues.

Data Requirements in RCM and Condition Monitoring

Reliability Centered Maintenance (RCM) requires comprehensive historical failure data, functional failure modes, and maintenance task effectiveness to develop an optimal maintenance strategy. Condition Monitoring depends heavily on real-time data acquisition from sensors measuring vibration, temperature, and other equipment condition parameters to predict asset health. Both approaches utilize data, but RCM relies on detailed failure and maintenance records while Condition Monitoring emphasizes continuous sensor data for immediate analysis.

Implementation Challenges and Considerations

Reliability Centered Maintenance (RCM) requires extensive data analysis and cross-departmental coordination, posing challenges in resource allocation and organizational change management. Condition monitoring depends heavily on sensor accuracy and real-time data integration, demanding substantial investment in technology and skilled personnel for effective implementation. Both methodologies necessitate rigorous training programs and continuous review processes to adapt maintenance strategies based on evolving asset conditions and operational priorities.

Cost Implications and Resource Allocation

Reliability Centered Maintenance (RCM) involves a thorough analysis to optimize maintenance strategies based on asset criticality, resulting in higher upfront costs but long-term savings through targeted interventions and reduced downtime. Condition Monitoring (CM) focuses on real-time data collection and analysis to predict equipment failures, requiring investment in specialized sensors and data analytics but enabling more efficient resource allocation by scheduling maintenance only when needed. RCM demands multidisciplinary expertise for implementation and planning, while CM relies on skilled technicians and advanced software, influencing labor costs and training requirements.

Impact on Equipment Reliability and Performance

Reliability Centered Maintenance (RCM) enhances equipment reliability by systematically identifying failure modes and prioritizing maintenance tasks based on risk, thereby maximizing operational performance and minimizing downtime. Condition Monitoring (CM) directly improves equipment performance through real-time data analysis, enabling early detection of anomalies and predictive maintenance interventions. Combining RCM with CM creates a synergistic approach that optimizes asset management, reduces unexpected failures, and extends equipment lifecycle.

Choosing the Right Approach for Your Operations

Reliability Centered Maintenance (RCM) emphasizes a structured analysis of asset criticality and failure modes to develop tailored maintenance strategies that maximize system reliability and safety. Condition Monitoring (CM) relies on real-time data from sensors and diagnostic tools to detect early signs of equipment degradation, enabling predictive maintenance interventions. Selecting the right approach depends on operational priorities, asset criticality, available resources, and desired balance between preventive actions and real-time condition insights for cost-effective maintenance management.

Reliability Centered Maintenance Infographic

libterm.com

libterm.com