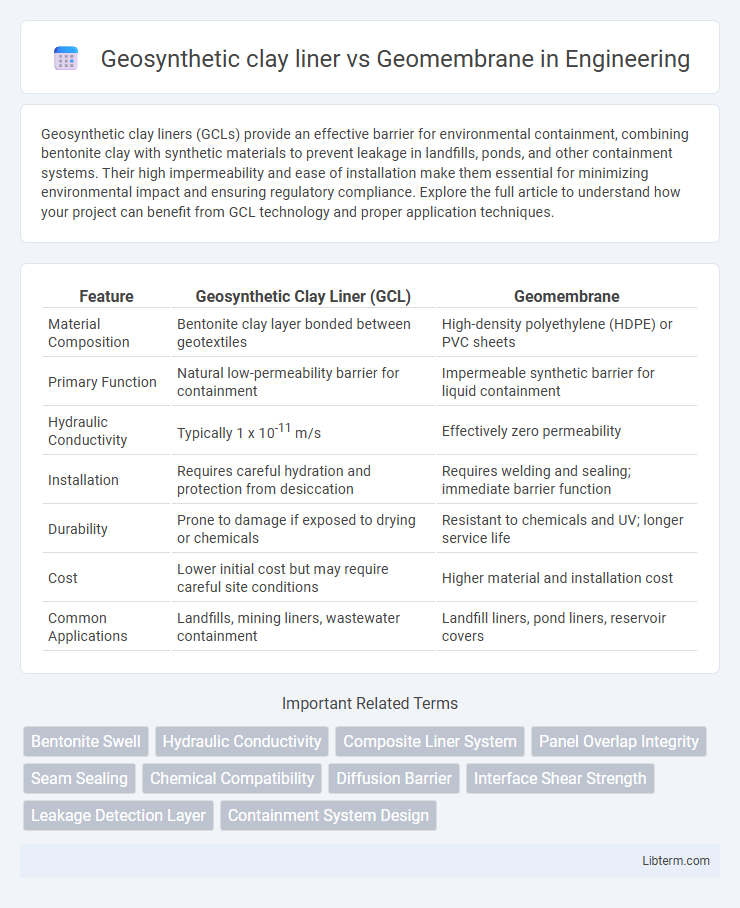

Geosynthetic clay liners (GCLs) provide an effective barrier for environmental containment, combining bentonite clay with synthetic materials to prevent leakage in landfills, ponds, and other containment systems. Their high impermeability and ease of installation make them essential for minimizing environmental impact and ensuring regulatory compliance. Explore the full article to understand how your project can benefit from GCL technology and proper application techniques.

Table of Comparison

| Feature | Geosynthetic Clay Liner (GCL) | Geomembrane |

|---|---|---|

| Material Composition | Bentonite clay layer bonded between geotextiles | High-density polyethylene (HDPE) or PVC sheets |

| Primary Function | Natural low-permeability barrier for containment | Impermeable synthetic barrier for liquid containment |

| Hydraulic Conductivity | Typically 1 x 10-11 m/s | Effectively zero permeability |

| Installation | Requires careful hydration and protection from desiccation | Requires welding and sealing; immediate barrier function |

| Durability | Prone to damage if exposed to drying or chemicals | Resistant to chemicals and UV; longer service life |

| Cost | Lower initial cost but may require careful site conditions | Higher material and installation cost |

| Common Applications | Landfills, mining liners, wastewater containment | Landfill liners, pond liners, reservoir covers |

Introduction to Geosynthetic Clay Liners and Geomembranes

Geosynthetic clay liners (GCLs) consist of a layer of bentonite clay sandwiched between geotextiles, providing low permeability and excellent hydraulic barrier properties for containment applications. Geomembranes, typically made from synthetic polymers like HDPE, offer robust impermeability and chemical resistance, making them ideal for preventing fluid migration in landfill liners, ponds, and reservoirs. Both materials serve as critical components in environmental protection and geotechnical engineering, with GCLs often used as a complement or alternative to geomembranes depending on project requirements and soil conditions.

Composition and Material Differences

Geosynthetic clay liners (GCLs) consist of a layer of natural sodium bentonite clay sandwiched between geotextiles or bonded to geomembranes, offering self-sealing properties due to the clay's swelling behavior upon hydration. In contrast, geomembranes are impermeable synthetic sheets made primarily from high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC), designed to provide a robust barrier against fluid migration. The key material difference lies in the GCL's reliance on natural clay minerals for hydraulic performance versus geomembranes' use of polymeric materials emphasizing mechanical strength and chemical resistance.

Key Functions and Applications

Geosynthetic clay liners (GCLs) provide effective low-permeability barriers through bentonite clay, offering self-sealing properties ideal for landfill liners, mining containment, and environmental protection projects. Geomembranes, composed of high-density polyethylene (HDPE) or other polymers, ensure exceptional chemical resistance and tensile strength, making them suitable for water reservoirs, wastewater treatment, and hazardous waste containment. Both materials play critical roles in geotechnical engineering by controlling fluid migration and enhancing containment system durability.

Installation Methods and Requirements

Geosynthetic clay liners (GCLs) require careful placement on a smooth, prepared subgrade to prevent punctures, followed by overlapping seams that are hydrated to activate the bentonite clay for a watertight barrier. Geomembranes demand precise seam welding using thermal or extrusion methods, with rigorous quality control measures such as vacuum testing to ensure leak-proof joints. Proper installation of both materials involves stringent site preparation, specialist equipment, and skilled labor to maintain the integrity and performance of containment systems.

Performance in Different Environmental Conditions

Geosynthetic clay liners (GCLs) provide excellent sealing performance in moderate temperature ranges and remain effective when exposed to freeze-thaw cycles due to their bentonite clay core, which swells upon hydration to create a low-permeability barrier. Geomembranes, typically made from high-density polyethylene (HDPE) or similar polymers, offer superior chemical resistance and durability in extreme temperatures, UV exposure, and aggressive chemical environments, maintaining structural integrity where GCLs may degrade. Performance in acidic leachates or highly saline conditions favors geomembranes, while GCLs perform optimally in environments with consistent moisture levels ensuring clay hydration.

Durability and Lifespan Comparison

Geosynthetic clay liners (GCLs) offer enhanced chemical resistance and self-sealing properties, making them highly durable in applications involving leachate containment and landfill liners, typically lasting 20 to 30 years under optimal conditions. Geomembranes, often made of HDPE or PVC, exhibit superior tensile strength and puncture resistance with expected lifespans ranging from 30 to 50 years depending on environmental exposure and installation quality. While GCLs provide cost-effective flexibility and ease of installation, geomembranes deliver longer-term structural integrity crucial for high-stress or exposed environments.

Cost Analysis and Economic Considerations

Geosynthetic clay liners (GCLs) typically offer lower initial installation costs compared to geomembranes due to reduced labor intensity and faster deployment. Geomembranes, while often more expensive upfront, provide superior chemical resistance and longevity, potentially reducing long-term maintenance and replacement expenses. Cost analysis must consider project-specific factors like site conditions, exposure risks, and life-cycle expenses to determine the most economically viable option.

Environmental Impact and Sustainability

Geosynthetic clay liners (GCLs) offer superior environmental protection by providing a natural, self-healing barrier that minimizes leakage and reduces contamination risk in landfills and containment systems, enhancing sustainability through lower carbon footprints. In contrast, geomembranes, made from synthetic polymers like HDPE, provide robust impermeability but involve higher environmental costs due to production processes and limited recyclability. Selecting GCLs over geomembranes can lead to more sustainable waste containment solutions by combining effective containment with reduced ecological impact and improved resource efficiency.

Typical Use Cases: Industry Examples

Geosynthetic clay liners (GCLs) are commonly used in landfill capping and base liners due to their excellent low permeability and self-sealing properties, making them ideal for hazardous waste containment and mining applications. Geomembranes, typically made from high-density polyethylene (HDPE), are favored in water reservoirs, wastewater treatment plants, and canal linings for their superior chemical resistance and durability. Both materials are essential in environmental engineering, with GCLs often combined with geomembranes in composite liners to enhance containment effectiveness.

Selecting the Best Barrier Solution

Geosynthetic clay liners (GCLs) provide a natural, flexible barrier with excellent self-sealing properties ideal for landfill liners and containment systems, while geomembranes offer superior impermeability and chemical resistance suited for harsh environments. Selecting the best barrier solution depends on site-specific factors such as permeability requirements, chemical exposure, and installation conditions. Combining GCLs with geomembranes often achieves enhanced protection by leveraging the strengths of both materials in engineered containment systems.

Geosynthetic clay liner Infographic

libterm.com

libterm.com