Structural systems form the backbone of any building, ensuring stability, strength, and durability under various loads and conditions. They include frameworks like beams, columns, trusses, and load-bearing walls designed to distribute weight efficiently and resist forces such as wind, gravity, and seismic activity. Discover how different structural systems impact your construction project and why selecting the right one is crucial by reading the full article.

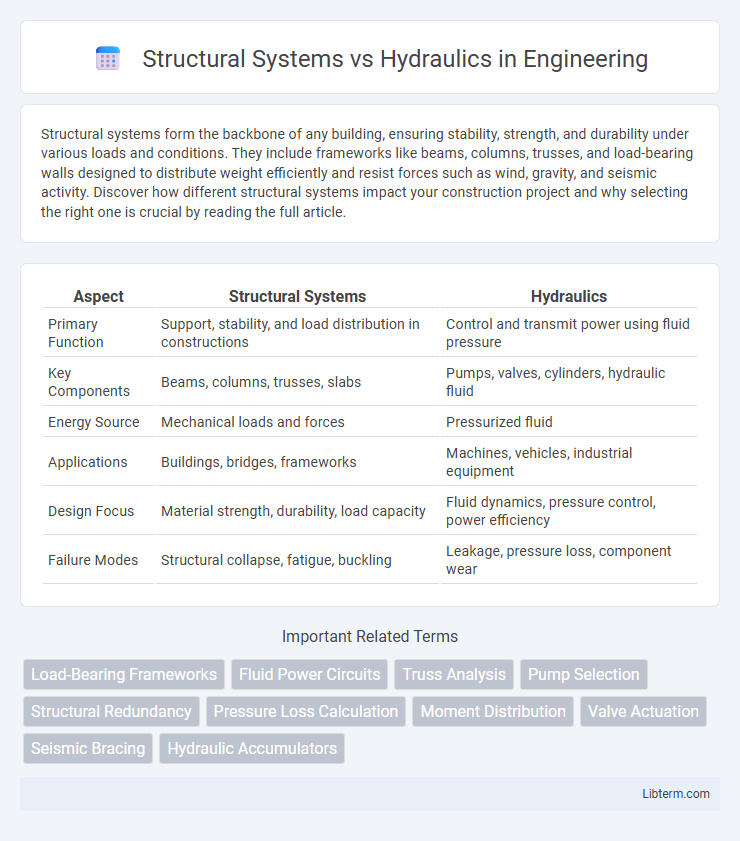

Table of Comparison

| Aspect | Structural Systems | Hydraulics |

|---|---|---|

| Primary Function | Support, stability, and load distribution in constructions | Control and transmit power using fluid pressure |

| Key Components | Beams, columns, trusses, slabs | Pumps, valves, cylinders, hydraulic fluid |

| Energy Source | Mechanical loads and forces | Pressurized fluid |

| Applications | Buildings, bridges, frameworks | Machines, vehicles, industrial equipment |

| Design Focus | Material strength, durability, load capacity | Fluid dynamics, pressure control, power efficiency |

| Failure Modes | Structural collapse, fatigue, buckling | Leakage, pressure loss, component wear |

Introduction to Structural Systems and Hydraulics

Structural systems provide the essential framework supporting buildings, bridges, and other constructions by efficiently managing loads and stresses through components like beams, columns, and trusses. Hydraulics involves the control and transmission of power using pressurized fluids, crucial for machinery, industrial equipment, and fluid transport systems. Understanding the principles of both structural systems and hydraulics enables engineers to design robust infrastructures and efficient fluid power mechanisms.

Core Principles of Structural Systems

Structural systems rely on the core principles of load distribution, material strength, and stability to ensure integrity and safety in buildings and bridges. These systems are designed to manage forces such as tension, compression, shear, and bending by utilizing elements like beams, columns, and trusses made from steel, concrete, or timber. Unlike hydraulics, which depend on fluid pressure and flow dynamics, structural systems focus on static and dynamic loads to resist deformation and collapse.

Fundamentals of Hydraulic Systems

Hydraulic systems operate based on fluid mechanics principles, using incompressible liquids to transmit power through components like pumps, valves, and cylinders. These systems rely on Pascal's Law, which states that pressure applied to a confined fluid is transmitted undiminished, enabling precise control of force and movement. Unlike structural systems that depend on mechanical support and load distribution, hydraulic systems focus on converting fluid pressure into mechanical energy for efficient motion and force application.

Key Differences Between Structural and Hydraulic Systems

Structural systems primarily involve the design and analysis of load-bearing frameworks made from materials like steel, concrete, or timber to ensure stability and strength. Hydraulic systems utilize fluid power through pressurized liquids to generate force and motion, involving components such as pumps, valves, and cylinders. Key differences lie in their functional purpose--structural systems support and transfer static and dynamic loads, while hydraulic systems convert fluid energy into mechanical energy for movement and control.

Applications of Structural Systems in Engineering

Structural systems are integral to civil, aerospace, and mechanical engineering, providing stability and support for buildings, bridges, and aircraft. They enable load distribution and resist forces such as tension, compression, and shear, ensuring safety and durability. Applications include framework design, foundation support, and structural analysis using materials like steel, concrete, and composites to optimize performance under various environmental conditions.

Common Uses of Hydraulics in Industry

Hydraulics are extensively utilized in industries for applications requiring precise control and powerful motion, such as in construction equipment like excavators, forklifts, and cranes. They dominate manufacturing processes involving presses, injection molding machines, and automated assembly lines due to their efficiency in transmitting force. Structural systems primarily provide support and stability, whereas hydraulics enable dynamic movement and force amplification in industrial machinery.

Advantages of Structural Systems

Structural systems provide superior load-bearing capacity and long-term durability compared to hydraulics, making them ideal for heavy and static applications such as bridges and buildings. They require less maintenance and have lower risk of failure due to wear or fluid leaks, enhancing safety and reliability. The energy efficiency of structural components reduces operational costs, while allowing precision in architectural design and engineering.

Benefits and Challenges of Hydraulic Systems

Hydraulic systems offer precise control and high power density, enabling smooth and efficient operation in heavy machinery and industrial applications, making them ideal for tasks requiring significant force and fine adjustments. Their ability to transmit power through incompressible fluids allows for compact and flexible system designs, which enhances performance in restricted spaces. However, hydraulic systems face challenges such as potential fluid leaks, maintenance complexity, and the need for strict cleanliness to prevent contamination and ensure reliability.

Integration of Structural and Hydraulic Systems

Integration of structural and hydraulic systems optimizes the performance and safety of infrastructure by ensuring that load-bearing elements and fluid control components work cohesively. Advanced sensor technology and real-time data analysis enable dynamic adjustments in both systems, enhancing resilience against environmental forces such as earthquakes and floods. This synergy reduces maintenance costs and improves the durability of bridges, dams, and water management facilities.

Future Trends in Structural and Hydraulic Technologies

Emerging trends in structural systems emphasize the integration of smart materials and adaptive design to enhance resilience and sustainability in construction. Hydraulic technologies are rapidly advancing with the adoption of IoT-enabled monitoring and automated control systems to optimize fluid flow and energy efficiency. The convergence of these fields leverages digital twins and AI-driven simulations to enable predictive maintenance and innovative infrastructure solutions.

Structural Systems Infographic

libterm.com

libterm.com