Dovetail joints provide exceptional strength and durability by interlocking wedge-shaped pins and tails, commonly used in woodworking for drawers and cabinets. This technique enhances both the structural integrity and aesthetic value of furniture, making it a preferred choice for fine craftsmanship. Discover how mastering dovetail joints can elevate your woodworking projects by exploring the rest of this article.

Table of Comparison

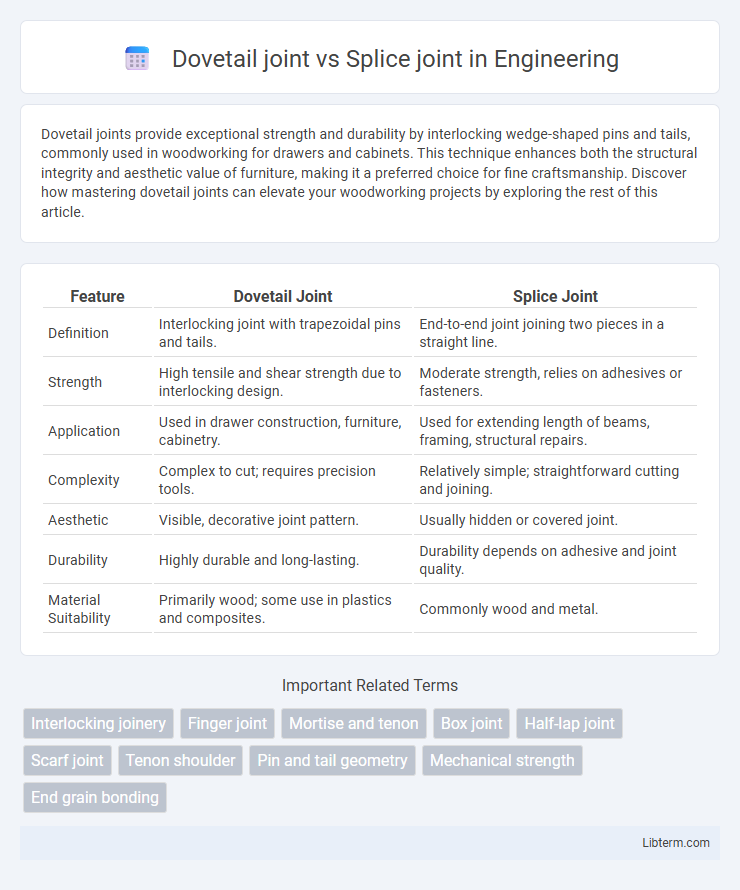

| Feature | Dovetail Joint | Splice Joint |

|---|---|---|

| Definition | Interlocking joint with trapezoidal pins and tails. | End-to-end joint joining two pieces in a straight line. |

| Strength | High tensile and shear strength due to interlocking design. | Moderate strength, relies on adhesives or fasteners. |

| Application | Used in drawer construction, furniture, cabinetry. | Used for extending length of beams, framing, structural repairs. |

| Complexity | Complex to cut; requires precision tools. | Relatively simple; straightforward cutting and joining. |

| Aesthetic | Visible, decorative joint pattern. | Usually hidden or covered joint. |

| Durability | Highly durable and long-lasting. | Durability depends on adhesive and joint quality. |

| Material Suitability | Primarily wood; some use in plastics and composites. | Commonly wood and metal. |

Introduction to Woodworking Joints

Dovetail joints provide superior strength and resistance to pulling forces, making them ideal for drawer construction and fine cabinetry due to their interlocking wedge-shaped design. Splice joints, in contrast, are used to extend the length of wood pieces by joining two boards end-to-end, offering less mechanical strength but allowing for smooth, continuous surfaces in woodworking projects. Understanding these joints is essential in woodworking for selecting the appropriate joint based on load-bearing requirements and aesthetic goals.

What is a Dovetail Joint?

A dovetail joint is a woodworking technique characterized by interlocking wedge-shaped projections called "tails" and corresponding "pins" that fit together tightly without the need for mechanical fasteners. This joint is renowned for its exceptional tensile strength and resistance to being pulled apart, making it ideal for drawer construction and box making. The precise angled cuts create a strong, durable connection that enhances both the structural integrity and aesthetic appeal of furniture pieces.

What is a Splice Joint?

A splice joint is a woodworking technique used to join two pieces of wood end-to-end for increased length or repair, often employing methods like scarf, finger, or butt joints to maximize structural integrity. Unlike the interlocking tails and pins of a dovetail joint, splice joints rely on surface contact and adhesives or fasteners to maintain strength. This joint is essential in creating longer beams or components in furniture and construction where seamless extension is required.

Structural Strength: Dovetail vs Splice

Dovetail joints exhibit superior structural strength due to their interlocking design, which provides excellent resistance to tensile and shear forces, making them ideal for drawer construction and high-stress applications. Splice joints, while effective for extending the length of wood pieces, rely heavily on adhesive and fasteners, resulting in lower mechanical strength compared to dovetails. The mechanical interlock in dovetail joints distributes load evenly, whereas splice joints depend more on bonding agents and reinforcement for adequate durability.

Aesthetic Appeal and Craftsmanship

Dovetail joints showcase superior aesthetic appeal due to their distinctive interlocking pattern, often admired for its intricate craftsmanship and visual elegance in fine woodworking. Splice joints, while functional and sometimes subtle in appearance, lack the decorative complexity that dovetail joints provide, making them less favored for projects emphasizing visual detail. The precision required to execute dovetail joints reflects a higher level of skill and dedication to traditional joinery techniques, enhancing the overall craftsmanship of the finished piece.

Common Applications of Dovetail Joints

Dovetail joints are commonly used in woodworking applications requiring high tensile strength and durability, such as in drawer construction, cabinet making, and fine furniture. Their interlocking design provides excellent resistance to being pulled apart, making them ideal for load-bearing corners. Unlike splice joints, which are often used to extend the length of wood pieces in framing or structural repairs, dovetail joints prioritize aesthetic appeal and mechanical strength in visible joinery.

Typical Uses of Splice Joints

Splice joints are typically used in woodworking and construction to extend the length of timber or metal components, often found in framing, beams, and poles where longer material spans are required. These joints provide strength and alignment in structural applications, making them ideal for repairing or joining sections that must bear significant loads. Unlike dovetail joints, which excel in drawer and box corners for their interlocking design, splice joints prioritize linear extension and load distribution in elongated assemblies.

Ease of Construction: Tools and Techniques

Dovetail joints require precise cutting tools such as dovetail saws, chisels, and marking gauges, demanding advanced woodworking skills and specialized techniques to achieve tight interlocking patterns. Splice joints, on the other hand, are simpler to construct using basic saws and clamps, relying mainly on straight cuts and glue, making them more accessible for beginners or quick repairs. While dovetail joints offer superior strength and aesthetics, splice joints provide easier and faster assembly with minimal tool investment.

Durability and Longevity Comparison

Dovetail joints offer superior durability and longevity due to their interlocking design, providing strong resistance against tensile and shear forces, making them ideal for load-bearing applications. In contrast, splice joints, often used for extending the length of timber or metal, rely more on adhesive or mechanical fasteners, which may degrade over time and are generally less robust under dynamic stress. The mechanical interlock of dovetail joints ensures a longer-lasting connection with minimal maintenance compared to the potentially weaker bond in splice joints.

Choosing the Right Joint for Your Project

Selecting between dovetail joints and splice joints depends on the project's structural and aesthetic requirements. Dovetail joints offer superior tensile strength and are ideal for drawer construction or visible corners due to their interlocking design and resistance to pulling apart. Splice joints are preferable for extending the length of wood pieces in applications where seamless connection and alignment are critical, but they generally require reinforcement for heavy loads.

Dovetail joint Infographic

libterm.com

libterm.com