Coated materials enhance surface properties such as durability, corrosion resistance, and aesthetic appeal through specialized layers applied to substrates. These coatings are essential in industries ranging from automotive to electronics, providing protective and functional benefits that extend product lifespan. Discover how different types of coated materials can transform your projects by reading the full article.

Table of Comparison

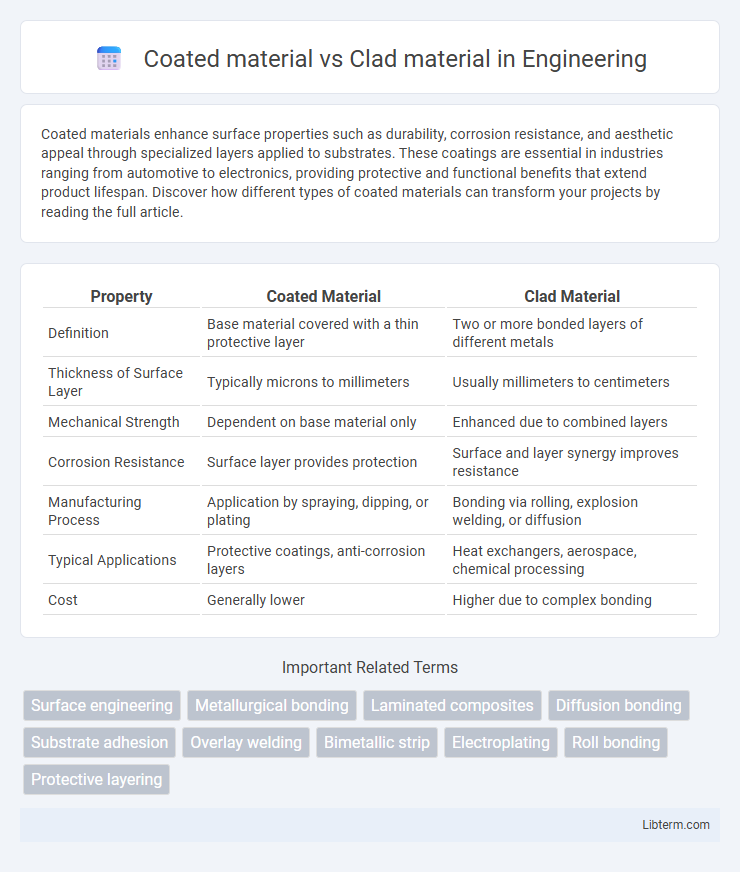

| Property | Coated Material | Clad Material |

|---|---|---|

| Definition | Base material covered with a thin protective layer | Two or more bonded layers of different metals |

| Thickness of Surface Layer | Typically microns to millimeters | Usually millimeters to centimeters |

| Mechanical Strength | Dependent on base material only | Enhanced due to combined layers |

| Corrosion Resistance | Surface layer provides protection | Surface and layer synergy improves resistance |

| Manufacturing Process | Application by spraying, dipping, or plating | Bonding via rolling, explosion welding, or diffusion |

| Typical Applications | Protective coatings, anti-corrosion layers | Heat exchangers, aerospace, chemical processing |

| Cost | Generally lower | Higher due to complex bonding |

Introduction to Coated and Clad Materials

Coated materials consist of a base substrate covered with a thin layer of another material to enhance surface properties such as corrosion resistance, wear resistance, or aesthetic appeal. Clad materials are composites formed by bonding layers of different metals or alloys together to combine their structural and functional benefits, commonly used in applications requiring strength and durability. Both coated and clad materials find extensive applications in industries like aerospace, automotive, and construction due to their tailored performance characteristics.

Definitions: What Are Coated Materials?

Coated materials consist of a base substrate covered with a thin layer of another material applied through processes like electroplating, painting, or chemical vapor deposition to enhance surface properties such as corrosion resistance, wear resistance, or aesthetic appearance. These coatings act as protective barriers that do not alter the underlying material's bulk properties but improve surface functionality. Common examples include powder-coated metals, anodized aluminum, and Teflon-coated cookware.

Understanding Clad Materials: Key Concepts

Clad materials consist of two or more layers of metals bonded together, combining the properties of each metal to enhance strength, corrosion resistance, and conductivity. Unlike coated materials, which have a thin surface layer applied for protection or aesthetics, clad materials offer integrated structural benefits through metallurgical bonding. The key advantage of clad materials lies in their ability to maintain a durable core with enhanced surface characteristics, making them ideal for applications in aerospace, electronics, and industrial equipment.

Manufacturing Processes: Coating vs. Cladding

Coated materials undergo a manufacturing process where a thin layer of protective or decorative material is applied onto the surface, typically through methods such as spraying, dipping, or chemical vapor deposition. Clad materials involve bonding two or more different metals or alloys together by applying heat and pressure, often using techniques like roll bonding, explosion welding, or vacuum cladding, to combine their properties. Coating primarily enhances surface characteristics, while cladding improves structural performance by integrating multiple material layers.

Material Performance: Durability and Corrosion Resistance

Coated materials exhibit enhanced corrosion resistance by applying a protective layer that shields the base substrate from environmental factors, significantly extending the material's lifespan. Clad materials, formed by metallurgically bonding layers of different metals, offer superior durability through a combination of properties such as corrosion resistance from the outer clad and mechanical strength from the inner core. While coated materials may degrade if the surface layer is compromised, clad materials maintain integrity and performance owing to their composite structure.

Cost Comparison: Coated vs. Clad Solutions

Coated materials typically offer a lower initial cost compared to clad materials due to simpler manufacturing processes and less expensive base materials. Clad materials, while generally more expensive upfront, provide superior durability and corrosion resistance, leading to lower maintenance and replacement costs over time. Evaluating total cost of ownership highlights that while coated solutions may be budget-friendly short term, clad materials often deliver better long-term value in demanding environments.

Applications in Industry: Where Each Excels

Coated materials excel in corrosion resistance and wear protection, making them ideal for automotive, aerospace, and machinery components where surface durability is critical. Clad materials, combining dissimilar metals through bonding, offer superior strength and thermal conductivity, widely used in electronics, chemical processing, and structural applications requiring both performance and cost-efficiency. Each material's unique properties enable tailored solutions for industries prioritizing surface protection or composite functionality.

Environmental Impact and Sustainability

Coated materials often involve the application of synthetic polymers or chemical layers that can introduce volatile organic compounds (VOCs) and hinder recyclability, increasing environmental burden compared to clad materials. Clad materials, formed by mechanically bonding layers of metals, typically exhibit enhanced recyclability and longer lifespans, reducing resource depletion and waste generation. Sustainable manufacturing favors clad materials due to their reduced chemical use, improved durability, and better potential for material recovery and circular economy integration.

Selection Criteria: Choosing the Right Material

Coated materials are selected for applications requiring enhanced surface properties like corrosion resistance and wear protection without altering the core material's mechanical characteristics. Clad materials are preferred when combining different metals to achieve a balance of strength, ductility, and corrosion resistance by bonding dissimilar metals at the core level. Selection criteria depend on factors such as environmental exposure, mechanical stress, cost-effectiveness, and the required lifespan of the component.

Future Trends in Surface Engineering Technology

Future trends in surface engineering technology emphasize advanced coated materials with enhanced wear resistance, corrosion protection, and multifunctional properties, driven by developments in nanotechnology and quantum materials. Clad materials continue to evolve through innovative metallurgical bonding techniques, enabling superior mechanical strength and thermal stability for aerospace and energy sectors. Integration of AI-driven design and additive manufacturing is set to optimize both coated and clad material applications, promoting sustainability and cost-efficiency.

Coated material Infographic

libterm.com

libterm.com