Electrostatic discharge (ESD) is the sudden flow of electricity between two electrically charged objects caused by contact or an electrical short. ESD can damage sensitive electronic components, leading to malfunctions or permanent failure. Discover how you can protect your devices and prevent costly damage by reading the rest of the article.

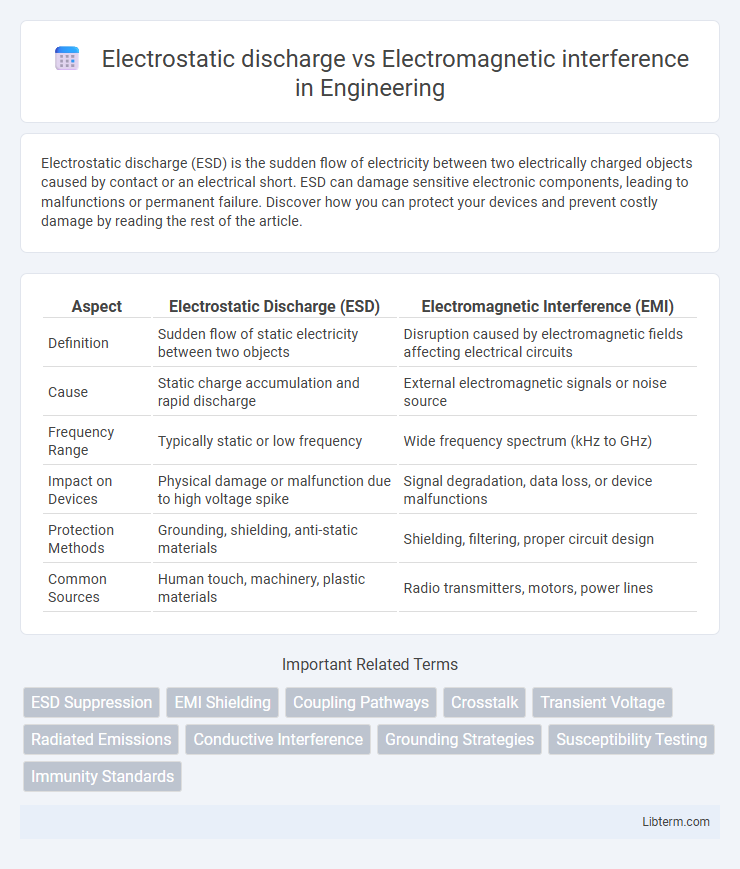

Table of Comparison

| Aspect | Electrostatic Discharge (ESD) | Electromagnetic Interference (EMI) |

|---|---|---|

| Definition | Sudden flow of static electricity between two objects | Disruption caused by electromagnetic fields affecting electrical circuits |

| Cause | Static charge accumulation and rapid discharge | External electromagnetic signals or noise source |

| Frequency Range | Typically static or low frequency | Wide frequency spectrum (kHz to GHz) |

| Impact on Devices | Physical damage or malfunction due to high voltage spike | Signal degradation, data loss, or device malfunctions |

| Protection Methods | Grounding, shielding, anti-static materials | Shielding, filtering, proper circuit design |

| Common Sources | Human touch, machinery, plastic materials | Radio transmitters, motors, power lines |

Introduction to Electrostatic Discharge (ESD) and Electromagnetic Interference (EMI)

Electrostatic Discharge (ESD) refers to the sudden flow of electricity between two electrically charged objects, often caused by contact or an electrical short, which can damage sensitive electronic components. Electromagnetic Interference (EMI) is the disturbance generated by external electromagnetic fields that disrupt electronic device operation and signal integrity. Understanding the mechanisms, sources, and effects of ESD and EMI is critical for designing robust electronic systems and ensuring compliance with industry standards such as IEC 61000 for EMI and ANSI/ESDA for ESD control.

Defining Electrostatic Discharge: Causes and Effects

Electrostatic discharge (ESD) occurs when a sudden flow of electricity transfers between two electrically charged objects due to contact or proximity, often caused by friction or material separation generating static charges. Common sources include human touch, electronic device handling, or environmental factors like low humidity, which can lead to damaging voltage spikes in sensitive circuits. ESD's effects range from minor glitches to severe component failure in electronics, necessitating proper grounding, antistatic materials, and protection protocols to mitigate damage.

Understanding Electromagnetic Interference: Sources and Impact

Electromagnetic interference (EMI) originates from sources such as electrical circuits, wireless devices, and power lines, disrupting signal integrity in electronic equipment. Unlike electrostatic discharge (ESD), which causes sudden voltage spikes, EMI results in continuous or sporadic noise affecting communication systems and sensitive components. Understanding EMI's impact is critical for designing effective shielding, grounding, and filtering solutions to maintain optimal device performance.

Key Differences Between ESD and EMI

Electrostatic discharge (ESD) involves the sudden transfer of static electricity between two objects with different electric potentials, causing sparks or damage primarily to sensitive electronic components. Electromagnetic interference (EMI) consists of unwanted electromagnetic waves that disrupt the normal operation of electronic devices by inducing noise or signals in circuits. Key differences include ESD's direct physical contact or close proximity causing immediate electrical discharge versus EMI's radiated or conducted disturbances affecting signal integrity over a broader frequency range.

Common Sources of ESD and EMI in Electronics

Common sources of Electrostatic Discharge (ESD) in electronics include human contact, friction between materials, and improper grounding, which generate sudden voltage spikes damaging sensitive components. Electromagnetic Interference (EMI) commonly originates from switching power supplies, radio frequency transmitters, and nearby electronic devices emitting fluctuating magnetic fields that disrupt signal integrity. Understanding these sources is crucial for implementing protective measures such as shielding, grounding, and filtering to enhance electronic device reliability.

Effects of ESD and EMI on Electronic Devices

Electrostatic discharge (ESD) causes sudden high-voltage surges that can damage sensitive electronic components by breaking down semiconductor junctions and causing permanent device failure. Electromagnetic interference (EMI) induces unwanted noise and signals in electronic circuits, leading to data corruption, signal degradation, and malfunction of communication systems. Both ESD and EMI compromise device reliability, with ESD typically causing immediate physical damage and EMI resulting in transient or persistent operational disruptions.

ESD and EMI Standards and Regulatory Compliance

Electrostatic discharge (ESD) and electromagnetic interference (EMI) are governed by distinct standards to ensure device reliability and safety in electronic systems. ESD standards such as IEC 61000-4-2 define testing and immunity requirements to protect sensitive components from sudden electrostatic discharges, while EMI compliance is regulated by standards like FCC Part 15 and CISPR that address radiated and conducted emissions limits. Regulatory compliance for both ESD and EMI is critical in industries including automotive, telecommunications, and medical devices to meet certification requirements and minimize operational disruptions caused by electrical disturbances.

Prevention and Mitigation Techniques for ESD

Prevention and mitigation techniques for Electrostatic Discharge (ESD) focus on controlling static electricity buildup through grounding, using anti-static wrist straps, and implementing conductive flooring in sensitive environments. Employing ESD-safe materials, such as static dissipative foams and bags, protects electronic components during handling and transport. Strict adherence to humidity control and personnel training minimizes the risk of ESD events, ensuring the reliability of electronic devices.

Control and Shielding Solutions for EMI

Effective control and shielding solutions for electromagnetic interference (EMI) involve the use of conductive enclosures, grounding techniques, and EMI filters to reduce unwanted electromagnetic radiation. Electrostatic discharge (ESD) control emphasizes static elimination methods such as ionizers, conductive mats, and proper grounding of personnel and equipment to prevent sudden discharge events. Combining ESD protection with EMI shielding materials like copper or aluminum foils ensures comprehensive defense against both static discharges and electromagnetic noise in sensitive electronic environments.

Best Practices for Managing ESD and EMI in Electronic Systems

Effective management of Electrostatic Discharge (ESD) and Electromagnetic Interference (EMI) in electronic systems requires implementing comprehensive grounding and shielding techniques to prevent voltage surges and signal distortion. Utilizing ESD-safe workstations, wrist straps, and ionizers mitigates static charge buildup, while EMI can be minimized through proper cable management, the use of ferrite beads, and EMI filtering components. Regular testing and adherence to industry standards such as IEC 61000 for EMI and ANSI/ESD S20.20 for ESD ensure robust protection and system reliability.

Electrostatic discharge Infographic

libterm.com

libterm.com