Preventive maintenance extends the lifespan of your equipment by addressing potential issues before they become costly problems. Regular inspections and timely repairs enhance operational efficiency and minimize unexpected downtime. Discover how implementing a preventive maintenance strategy can safeguard your assets and improve productivity throughout this article.

Table of Comparison

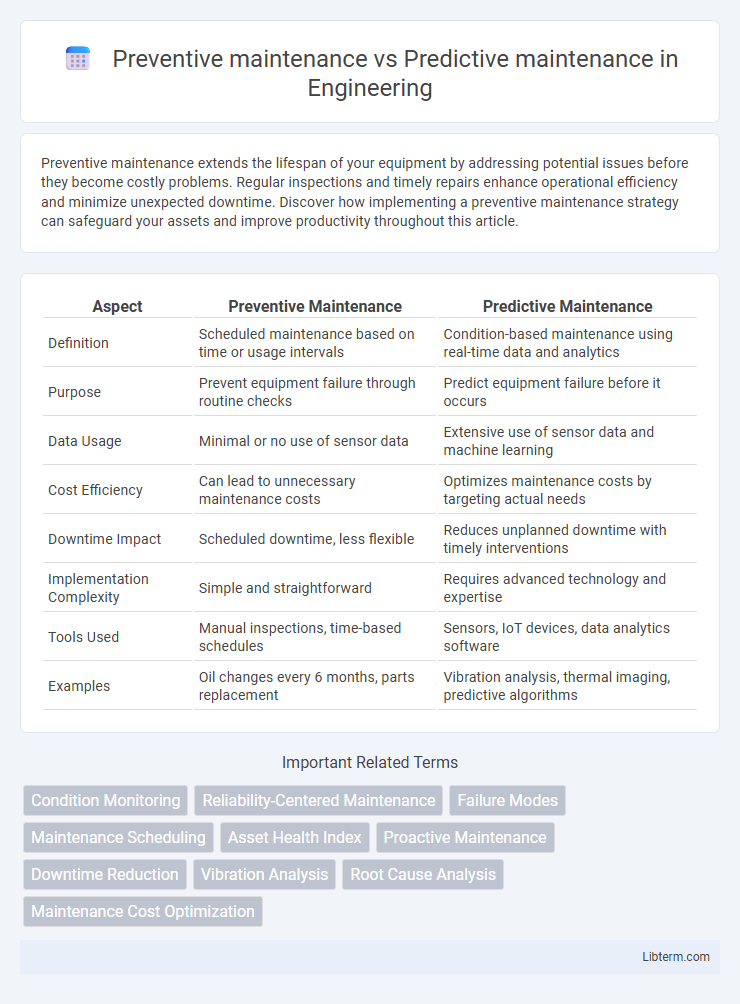

| Aspect | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Definition | Scheduled maintenance based on time or usage intervals | Condition-based maintenance using real-time data and analytics |

| Purpose | Prevent equipment failure through routine checks | Predict equipment failure before it occurs |

| Data Usage | Minimal or no use of sensor data | Extensive use of sensor data and machine learning |

| Cost Efficiency | Can lead to unnecessary maintenance costs | Optimizes maintenance costs by targeting actual needs |

| Downtime Impact | Scheduled downtime, less flexible | Reduces unplanned downtime with timely interventions |

| Implementation Complexity | Simple and straightforward | Requires advanced technology and expertise |

| Tools Used | Manual inspections, time-based schedules | Sensors, IoT devices, data analytics software |

| Examples | Oil changes every 6 months, parts replacement | Vibration analysis, thermal imaging, predictive algorithms |

Introduction to Maintenance Strategies

Preventive maintenance involves scheduled inspections and routine servicing to reduce equipment failure and extend asset lifespan, relying on time-based intervals or usage cycles. Predictive maintenance uses real-time data and condition-monitoring technologies like vibration analysis and thermal imaging to forecast potential failures and perform maintenance only when necessary. These maintenance strategies optimize operational efficiency, minimize downtime, and improve asset reliability in industrial and manufacturing settings.

What is Preventive Maintenance?

Preventive maintenance involves regularly scheduled inspections and servicing of equipment to prevent unexpected failures and extend asset lifespan. It relies on time-based intervals or usage cycles to perform tasks such as lubrication, adjustments, and part replacements. This proactive approach minimizes downtime and improves reliability by addressing potential issues before they cause breakdowns.

What is Predictive Maintenance?

Predictive maintenance uses real-time data and advanced analytics to monitor equipment condition and predict failures before they occur, minimizing unplanned downtime. It relies on IoT sensors, machine learning algorithms, and condition-based monitoring to track parameters such as vibration, temperature, and wear. This proactive approach enables efficient scheduling of maintenance activities, reducing costs and extending asset lifespan compared to traditional preventive maintenance.

Key Differences Between Preventive and Predictive Maintenance

Preventive maintenance schedules regular equipment inspections and part replacements based on time or usage intervals, aiming to reduce the likelihood of unexpected failures. Predictive maintenance employs real-time data analytics and condition monitoring technologies, such as vibration analysis or thermal imaging, to forecast failures and perform maintenance only when necessary. Key differences include preventive maintenance's reliance on fixed schedules versus predictive maintenance's data-driven approach, which optimizes maintenance timing and minimizes downtime and costs.

Advantages of Preventive Maintenance

Preventive maintenance extends equipment lifespan by scheduling regular inspections and repairs before failures occur, reducing unexpected downtime and costly emergency repairs. It ensures consistent performance and safety compliance through routine upkeep, which lowers overall maintenance expenses compared to reactive approaches. This proactive strategy simplifies maintenance planning and resource allocation by standardizing tasks at fixed intervals.

Benefits of Predictive Maintenance

Predictive maintenance leverages real-time data and advanced analytics to accurately forecast equipment failures, minimizing unplanned downtime and reducing maintenance costs. It enhances asset lifespan by enabling timely interventions based on actual condition rather than preset schedules. This approach improves operational efficiency and reliability, leading to higher productivity and reduced resource waste.

Cost Comparison: Preventive vs Predictive Maintenance

Preventive maintenance typically incurs higher labor and downtime costs due to scheduled servicing regardless of equipment condition, leading to potential unnecessary part replacements. Predictive maintenance leverages real-time data analytics and condition monitoring to perform repairs only when needed, significantly reducing unexpected failures and optimizing maintenance expenses. Over time, predictive maintenance demonstrates lower total cost of ownership by minimizing downtime and extending asset lifespan compared to preventive maintenance.

Choosing the Right Maintenance Approach

Choosing the right maintenance approach depends on factors such as equipment criticality, operational costs, and failure patterns. Preventive maintenance involves scheduled tasks based on time or usage intervals, reducing unexpected breakdowns but potentially leading to unnecessary servicing. Predictive maintenance leverages real-time data and condition-monitoring technologies to forecast failures, optimizing resource allocation and minimizing downtime by addressing issues only when needed.

Industry Applications and Use Cases

Preventive maintenance involves scheduled inspections and part replacements in industries such as manufacturing and aviation to reduce unexpected equipment failures, while predictive maintenance uses real-time sensor data and machine learning algorithms to forecast equipment issues in sectors like energy, automotive, and oil & gas. In manufacturing, predictive maintenance optimizes production uptime by analyzing vibration, temperature, and acoustic data, whereas preventive maintenance ensures routine calibration and lubrication tasks. Oil refineries leverage predictive analytics for early fault detection, minimizing downtime, whereas preventive strategies enforce strict maintenance intervals to comply with safety regulations.

Future Trends in Maintenance Technology

Future trends in maintenance technology emphasize the integration of AI-driven predictive maintenance systems that analyze real-time sensor data to forecast equipment failures more accurately than traditional preventive maintenance schedules. Advances in IoT connectivity and machine learning algorithms enable continuous condition monitoring, reducing downtime and maintenance costs while optimizing asset lifespan. The evolution toward autonomous maintenance platforms harnesses big data analytics and edge computing to facilitate proactive interventions based on precise operational patterns.

Preventive maintenance Infographic

libterm.com

libterm.com