Strength is the foundation of physical and mental resilience, enabling you to overcome challenges and achieve your goals. Building strength involves consistent training, proper nutrition, and adequate recovery to maximize performance and prevent injury. Discover effective strategies to enhance your strength and unlock your full potential by reading the rest of this article.

Table of Comparison

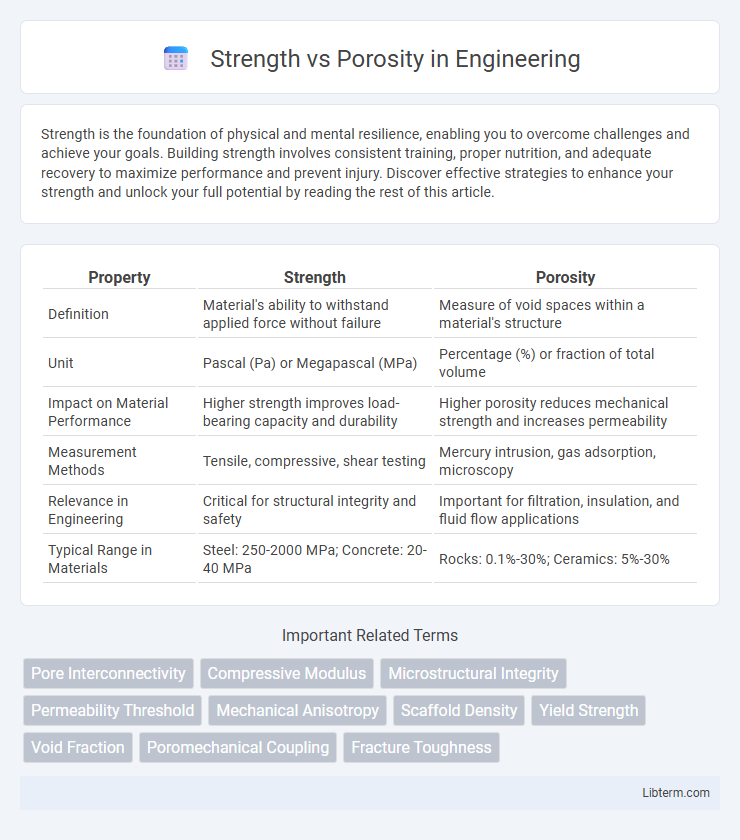

| Property | Strength | Porosity |

|---|---|---|

| Definition | Material's ability to withstand applied force without failure | Measure of void spaces within a material's structure |

| Unit | Pascal (Pa) or Megapascal (MPa) | Percentage (%) or fraction of total volume |

| Impact on Material Performance | Higher strength improves load-bearing capacity and durability | Higher porosity reduces mechanical strength and increases permeability |

| Measurement Methods | Tensile, compressive, shear testing | Mercury intrusion, gas adsorption, microscopy |

| Relevance in Engineering | Critical for structural integrity and safety | Important for filtration, insulation, and fluid flow applications |

| Typical Range in Materials | Steel: 250-2000 MPa; Concrete: 20-40 MPa | Rocks: 0.1%-30%; Ceramics: 5%-30% |

Understanding the Relationship Between Strength and Porosity

Porosity directly influences the mechanical strength of materials by dictating the volume of voids within a solid matrix, where higher porosity generally leads to lower strength due to reduced load-bearing cross-section. The relationship between strength and porosity is often characterized by models such as the Gibson-Ashby equation, which predicts strength degradation as a function of porosity percentage. Precise control and measurement of porosity in materials like ceramics, metals, and polymers enable optimization of their mechanical properties for applications demanding specific strength thresholds.

Defining Material Strength: Key Concepts

Material strength is the ability of a substance to withstand applied forces without failure, characterized by parameters such as tensile strength, compressive strength, and shear strength. Porosity directly influences strength by creating voids that reduce load-bearing capacity and initiate crack propagation under stress. Optimizing material strength involves controlling porosity levels through manufacturing processes to enhance durability and mechanical performance.

What Is Porosity and Why Does It Matter?

Porosity refers to the measure of void spaces within a material, typically expressed as a percentage of the total volume. It significantly impacts a material's strength by determining how much empty space exists, which can weaken structural integrity and reduce durability. Understanding porosity is crucial in industries like construction, geology, and material science, where controlling porosity ensures optimal strength and performance of materials.

How Porosity Affects Mechanical Strength

Porosity significantly reduces mechanical strength by creating voids and discontinuities within a material's microstructure, which act as stress concentration points and crack initiation sites. Higher porosity leads to decreased load-bearing capacity, lower fracture toughness, and increased susceptibility to fatigue failure. Materials with minimal porosity exhibit enhanced durability and resistance to mechanical deformation.

Factors Influencing Porosity in Materials

Porosity in materials is primarily influenced by particle size distribution, compaction pressure, and the presence of voids or defects during processing, which directly affect the mechanical strength and durability. Higher porosity typically reduces strength due to increased void spaces disrupting stress distribution, while optimized grain bonding and minimized pore volume enhance load-bearing capacity. Controlling sintering temperature and cooling rates also plays a critical role in tailoring porosity and, consequently, the structural performance of ceramics and metals.

Measuring Strength in Porous Materials

Measuring strength in porous materials requires specialized techniques due to the complex internal structure affecting load distribution and fracture behavior. Methods such as micro-indentation, uniaxial compression, and nanoindentation provide quantitative data on mechanical properties while accounting for porosity levels. Accurate strength assessment integrates porosity parameters like pore size, distribution, and volume fraction to predict material performance and durability effectively.

Strategies to Balance Strength and Porosity

Optimizing the balance between strength and porosity involves tailoring material composition and microstructure, such as controlling pore size distribution and volume fraction to enhance mechanical performance without compromising permeability. Advanced manufacturing techniques like additive manufacturing and sintering allow precise manipulation of porosity while maintaining structural integrity. Incorporating nano-reinforcements or hierarchical porosity designs further improves strength-to-weight ratios, enabling materials to meet specific functional requirements.

Applications Requiring High Strength and Low Porosity

Materials with high strength and low porosity are critical in aerospace and automotive industries where structural integrity and durability under stress are paramount. Advanced composites and dense metals exhibit optimal performance by minimizing voids that can act as crack initiation sites, ensuring longevity and safety in components such as aircraft frames and vehicle chassis. High-strength, low-porosity materials also enhance wear resistance and reduce corrosion risk, proving essential in demanding engineering applications.

Innovations in Controlling Porosity for Enhanced Strength

Innovations in controlling porosity focus on optimizing pore size distribution and reducing void volume to significantly enhance material strength. Advanced techniques like additive manufacturing and nanostructured coatings allow precise manipulation of porosity, resulting in materials with superior mechanical properties and durability. Research integrating pore architecture engineering and real-time monitoring has enabled breakthroughs in producing high-strength composites with controlled porosity levels tailored for specific applications.

Future Trends: Optimizing Strength vs Porosity in Advanced Materials

Future trends in optimizing strength versus porosity in advanced materials emphasize the development of nano-engineered composites and biomimetic structures to achieve superior mechanical properties without sacrificing material permeability. Additive manufacturing techniques like selective laser sintering enable precise control over pore size and distribution, enhancing toughness and functionality in aerospace and biomedical applications. Machine learning algorithms increasingly predict ideal microstructures, accelerating the discovery of materials with balanced strength-to-porosity ratios tailored for specific high-performance uses.

Strength Infographic

libterm.com

libterm.com