Permanent Magnet Synchronous Motors (PMSMs) offer high efficiency and precise control, making them ideal for applications requiring rapid dynamic response and energy savings. Synchronous Reluctance Motors provide robust performance with a simpler construction and improved reliability due to the absence of permanent magnets, reducing maintenance costs. Explore the detailed comparison in the article to understand which motor best suits your specific application needs.

Table of Comparison

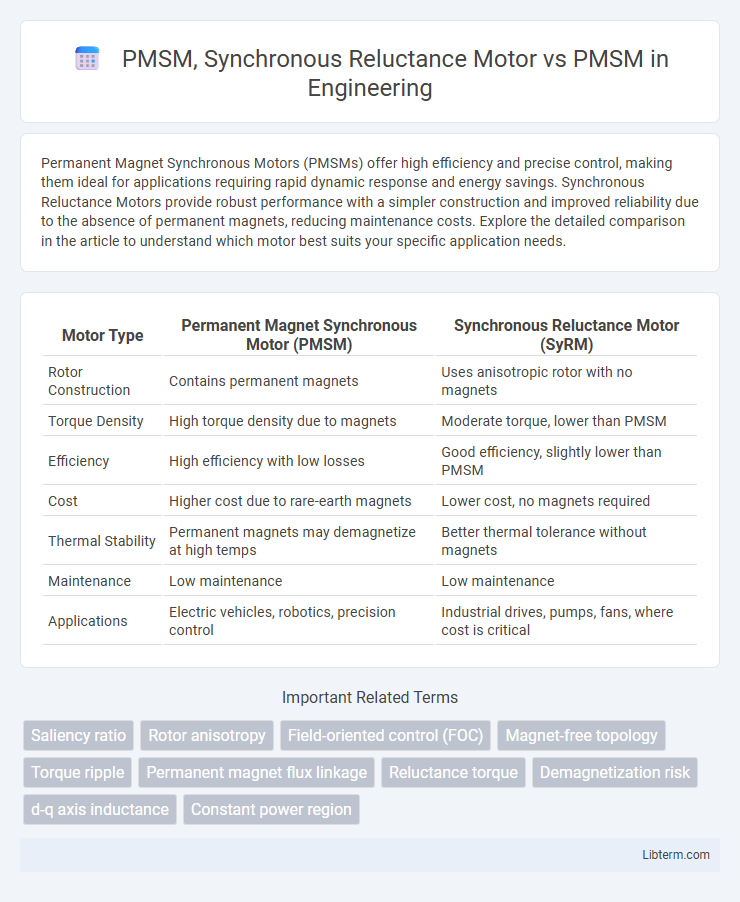

| Motor Type | Permanent Magnet Synchronous Motor (PMSM) | Synchronous Reluctance Motor (SyRM) |

|---|---|---|

| Rotor Construction | Contains permanent magnets | Uses anisotropic rotor with no magnets |

| Torque Density | High torque density due to magnets | Moderate torque, lower than PMSM |

| Efficiency | High efficiency with low losses | Good efficiency, slightly lower than PMSM |

| Cost | Higher cost due to rare-earth magnets | Lower cost, no magnets required |

| Thermal Stability | Permanent magnets may demagnetize at high temps | Better thermal tolerance without magnets |

| Maintenance | Low maintenance | Low maintenance |

| Applications | Electric vehicles, robotics, precision control | Industrial drives, pumps, fans, where cost is critical |

Introduction to PMSM

Permanent Magnet Synchronous Motors (PMSMs) use rare-earth magnets embedded in the rotor, delivering high efficiency, power density, and precise speed control in industrial applications. Synchronous Reluctance Motors (SynRMs) lack permanent magnets and rely on rotor saliency to generate torque, resulting in lower cost but reduced torque density compared to PMSMs. PMSMs outperform SynRMs in efficiency and dynamic response, making them ideal for electric vehicles and robotics where performance and energy savings are critical.

Overview of Synchronous Reluctance Motor

Synchronous Reluctance Motors (SynRM) feature a rotor design that relies on the magnetic reluctance difference between the rotor's d-axis and q-axis, enabling torque generation without permanent magnets. They offer high efficiency and robustness, especially in applications requiring low maintenance and reduced cost compared to Permanent Magnet Synchronous Motors (PMSM). SynRMs provide a competitive alternative in industrial drives by combining reliable synchronous operation with simplified rotor construction.

Construction Differences: PMSM vs Synchronous Reluctance Motor

Permanent Magnet Synchronous Motors (PMSM) feature permanent magnets embedded in or surface-mounted on the rotor, generating a constant magnetic field that enables high torque density and efficiency. In contrast, Synchronous Reluctance Motors (SynRM) rely on rotor saliency without magnets, utilizing anisotropic rotor structures to create reluctance torque through differences in magnetic reluctance. The absence of rare-earth magnets in SynRMs results in simpler rotor construction and lower material costs compared to the magnet-dependent PMSM rotors.

Operating Principles of PMSM

Permanent Magnet Synchronous Motors (PMSMs) operate based on the interaction between the rotating magnetic field generated by the stator windings and the constant magnetic field of the rotor's permanent magnets. This synchronous operation ensures high efficiency, precise speed control, and strong torque output. Unlike Synchronous Reluctance Motors that rely on rotor saliency to generate torque, PMSMs achieve torque production predominantly through the excitation of the rotor's embedded permanent magnets, resulting in superior performance and power density.

Operating Principles of Synchronous Reluctance Motor

The operating principle of the Synchronous Reluctance Motor (SynRM) is based on the rotor's magnetic saliency, where torque is produced by the tendency of the rotor to align with the stator's rotating magnetic field, exploiting the rotor's varying reluctance. Unlike the Permanent Magnet Synchronous Motor (PMSM) that utilizes embedded permanent magnets to generate a constant rotor magnetic field, the SynRM generates torque solely through the anisotropy of its rotor structure without magnets. This distinction makes the SynRM highly efficient in applications requiring robustness against high temperatures and cost-sensitive environments due to the absence of expensive rare-earth magnets.

Efficiency and Performance Comparison

Permanent Magnet Synchronous Motors (PMSM) typically offer higher efficiency and superior performance due to their use of rare-earth magnets, which provide consistent magnetic flux and reduce energy losses compared to Synchronous Reluctance Motors (SynRM). Synchronous Reluctance Motors achieve efficiency through rotor design that minimizes magnetic losses but generally exhibit lower torque density and overall performance than PMSMs, especially under variable load conditions. PMSMs excel in applications demanding high precision and dynamic response, while SynRMs present a cost-effective, lower-maintenance alternative with moderate efficiency.

Torque and Speed Characteristics

Permanent Magnet Synchronous Motors (PMSM) deliver high torque density and precise speed control due to their rotor-mounted permanent magnets, enabling efficient performance across a wide speed range. Synchronous Reluctance Motors (SynRM) exhibit lower torque density and less dynamic response because their torque generation relies on rotor saliency without magnets. PMSMs generally achieve higher peak torque and better speed stability, making them preferred for applications demanding high power density and rapid acceleration.

Cost and Material Considerations

Permanent Magnet Synchronous Motors (PMSMs) typically involve higher material costs due to rare-earth magnets like neodymium, which contribute to increased manufacturing expenses compared to Synchronous Reluctance Motors (SynRMs) that rely on laminated steel and rotor saliency without magnets. Synchronous Reluctance Motors offer cost advantages by avoiding the use of expensive permanent magnets and minimizing dependence on critical raw materials, making them more suitable for applications sensitive to price volatility and supply chain risks. While PMSMs deliver superior torque density and efficiency owing to high-energy magnets, SynRMs provide a more economical alternative by leveraging rotor geometry and magnetic anisotropy to achieve synchronous operation without costly magnetic materials.

Application Areas: PMSM vs Synchronous Reluctance Motor

Permanent Magnet Synchronous Motors (PMSM) excel in high-precision applications such as electric vehicles, robotics, and aerospace due to their superior torque density and efficiency. Synchronous Reluctance Motors (SynRM) find widespread use in HVAC systems, pumps, and industrial drives where cost-effectiveness and reliability are prioritized over peak performance. The choice between PMSM and SynRM largely depends on application-specific demands for efficiency, torque ripple, and operational cost.

Summary: Choosing Between PMSM and Synchronous Reluctance Motor

PMSM (Permanent Magnet Synchronous Motor) offers high efficiency, excellent torque density, and precise control, making it ideal for applications requiring superior performance and compact size. Synchronous Reluctance Motors provide a cost-effective solution with robust structure and less dependency on rare-earth materials, suitable for industries prioritizing sustainability and lower maintenance. Choosing between PMSM and Synchronous Reluctance Motor depends on balancing performance demands, material costs, and application-specific operational requirements.

PMSM, Synchronous Reluctance Motor Infographic

libterm.com

libterm.com