Derivative control enhances system stability by predicting future errors based on the rate of change, allowing for quicker and more precise adjustments in feedback loops. It helps to reduce overshoot and oscillations in control systems by responding to the velocity of the error, improving overall performance. Explore the rest of this article to understand how derivative control can optimize your system's responsiveness and accuracy.

Table of Comparison

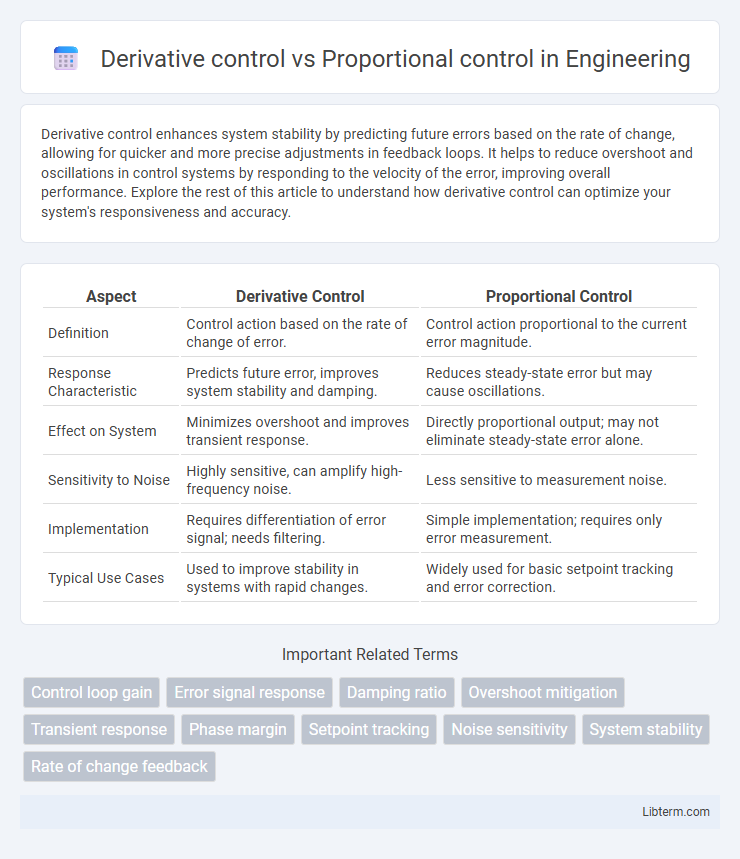

| Aspect | Derivative Control | Proportional Control |

|---|---|---|

| Definition | Control action based on the rate of change of error. | Control action proportional to the current error magnitude. |

| Response Characteristic | Predicts future error, improves system stability and damping. | Reduces steady-state error but may cause oscillations. |

| Effect on System | Minimizes overshoot and improves transient response. | Directly proportional output; may not eliminate steady-state error alone. |

| Sensitivity to Noise | Highly sensitive, can amplify high-frequency noise. | Less sensitive to measurement noise. |

| Implementation | Requires differentiation of error signal; needs filtering. | Simple implementation; requires only error measurement. |

| Typical Use Cases | Used to improve stability in systems with rapid changes. | Widely used for basic setpoint tracking and error correction. |

Introduction to Control Systems

Derivative control measures the rate of change of the error signal, providing predictive action that improves system stability and reduces overshoot in control systems. Proportional control adjusts the output proportionally to the current error, offering straightforward correction but may result in steady-state error. Combining derivative and proportional controls enhances system response by balancing immediate error correction with anticipation of future trends.

Understanding Proportional Control

Proportional control adjusts the output proportionally to the current error value, providing a direct response to system deviations. This method improves system stability by reducing steady-state error without causing excessive oscillations, making it effective for processes requiring precise control. Compared to derivative control that reacts to the rate of error change, proportional control emphasizes correcting the magnitude of the error for immediate system correction.

Exploring Derivative Control

Derivative control predicts system behavior by calculating the rate of change of the error, providing faster response and improved stability compared to proportional control alone. It effectively reduces overshoot and oscillations by dampening the system response, making it essential in applications requiring precise control such as motion systems and temperature regulation. Unlike proportional control, which adjusts output based on current error magnitude, derivative control anticipates future error trends, enhancing control accuracy and system robustness.

Key Differences Between Proportional and Derivative Control

Proportional control adjusts the output proportionally to the current error value, providing immediate corrective action that reduces steady-state error but may cause oscillations. Derivative control responds to the rate of change of the error, predicting future errors and enhancing system stability by dampening oscillations and improving transient response. The key difference lies in proportional control addressing present error magnitude, while derivative control focuses on error trend, making them complementary in PID control systems.

Mathematical Representation of Proportional and Derivative Control

Proportional control is mathematically represented as \( u(t) = K_p e(t) \), where \( u(t) \) is the control output, \( K_p \) is the proportional gain, and \( e(t) \) is the error signal. Derivative control is characterized by \( u(t) = K_d \frac{d}{dt} e(t) \), where \( K_d \) denotes the derivative gain and the derivative term predicts future error behavior based on its rate of change. The combined effect in a PD controller is \( u(t) = K_p e(t) + K_d \frac{d}{dt} e(t) \), enhancing system stability by responding to both the present error and its rate of change.

Advantages of Proportional Control

Proportional control offers the advantage of simplicity and ease of implementation, making it effective for systems requiring straightforward error correction. It provides a stable and continuous response by adjusting the control output proportionally to the error magnitude, minimizing steady-state error in many applications. Compared to derivative control, proportional control is less sensitive to noise and disturbances, enhancing system robustness in various industrial control processes.

Benefits of Derivative Control

Derivative control enhances system stability by predicting future errors based on the rate of change, thus reducing overshoot and oscillations commonly seen in proportional control. It improves response time and dampens system fluctuations, leading to smoother and more precise control outputs. This predictive capability is especially beneficial in processes with rapid dynamics or where minimizing transient deviations is critical.

Applications of Proportional and Derivative Control

Proportional control is widely used in temperature regulation systems, motor speed control, and robotic actuators for its ability to reduce steady-state error by applying corrective action proportional to the error magnitude. Derivative control finds applications in systems requiring predictive adjustment, such as vibration damping in mechanical systems, flight control systems in aerospace, and position control in servo mechanisms, by responding to the rate of error change to improve stability and prevent overshoot. Combining proportional and derivative control enhances system responsiveness and accuracy in industrial process control, automotive cruise control, and robotic arm positioning.

Limitations and Challenges in Both Methods

Derivative control faces challenges such as sensitivity to noise, which can cause excessive system oscillations and instability, complicating precise tuning in dynamic environments. Proportional control struggles with steady-state errors and cannot eliminate offset without integration, limiting accuracy in maintaining target setpoints. Both methods encounter difficulties in handling nonlinear processes and abrupt disturbances, requiring careful parameter adjustment to balance responsiveness and stability.

Choosing the Right Control Strategy

Choosing the right control strategy depends on the system dynamics and desired response characteristics. Proportional control provides a straightforward approach with a control output proportional to the error, ideal for systems requiring steady-state accuracy but may result in steady-state error. Derivative control predicts system behavior by responding to the rate of change of the error, improving stability and reducing overshoot in systems with rapid disturbances or noise sensitivity.

Derivative control Infographic

libterm.com

libterm.com