PLC and PC-based control systems offer distinct advantages in industrial automation, with PLCs known for their reliability and real-time processing capabilities, while PC-based controllers provide greater flexibility and advanced computational power. Understanding how these technologies complement each other can optimize Your control strategies and enhance overall system performance. Explore the rest of the article to learn how to select and integrate the best control solution for Your applications.

Table of Comparison

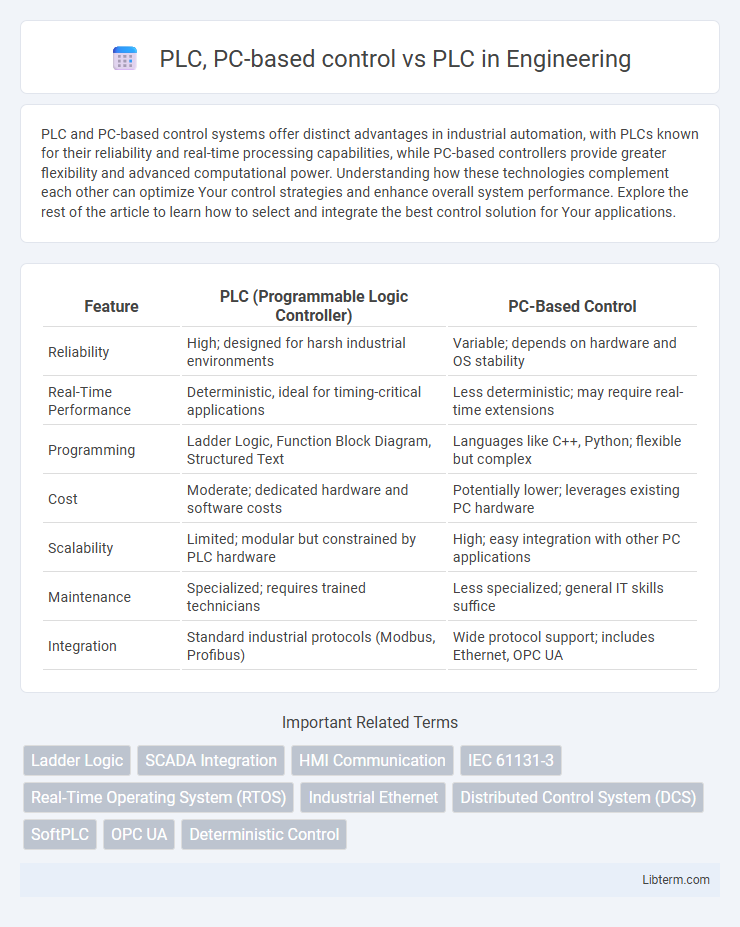

| Feature | PLC (Programmable Logic Controller) | PC-Based Control |

|---|---|---|

| Reliability | High; designed for harsh industrial environments | Variable; depends on hardware and OS stability |

| Real-Time Performance | Deterministic, ideal for timing-critical applications | Less deterministic; may require real-time extensions |

| Programming | Ladder Logic, Function Block Diagram, Structured Text | Languages like C++, Python; flexible but complex |

| Cost | Moderate; dedicated hardware and software costs | Potentially lower; leverages existing PC hardware |

| Scalability | Limited; modular but constrained by PLC hardware | High; easy integration with other PC applications |

| Maintenance | Specialized; requires trained technicians | Less specialized; general IT skills suffice |

| Integration | Standard industrial protocols (Modbus, Profibus) | Wide protocol support; includes Ethernet, OPC UA |

Introduction to PLC and PC-Based Control

Programmable Logic Controllers (PLCs) are industrial digital computers designed for automation of electromechanical processes, offering real-time deterministic control and robustness in harsh environments. PC-based control leverages standard personal computers with software-based controllers, providing flexibility, complex algorithms, and high processing power but potentially lower reliability in industrial settings. Integrating PLCs ensures precise I/O handling and fault tolerance, while PC-based control excels in data analytics and user interface capabilities, making each suitable for different automation needs.

Core Concepts: PLC vs. PC-Based Control

Programmable Logic Controllers (PLCs) are specialized industrial computers designed for real-time, deterministic control of automation processes with rugged hardware optimized for harsh environments. PC-based control leverages standard personal computer platforms running industrial control software, offering greater flexibility, higher processing power, and easier integration with complex data analytics and visualization tools. Core differences include PLCs' dedicated input/output (I/O) modules and ladder logic programming versus PC-based systems' general-purpose I/O and software-driven control architectures, influencing system reliability, scalability, and maintenance.

Hardware Architecture Comparison

PLC hardware architecture features dedicated processors, specialized input/output modules, and real-time operating systems optimized for industrial automation tasks. PC-based control systems utilize general-purpose processors, standard input/output interfaces, and operating systems that provide greater flexibility but may require additional real-time extensions to achieve deterministic performance. PLCs offer robust, ruggedized designs with high reliability in harsh environments, while PC-based controllers excel in scalability and integration with advanced software tools for complex control strategies.

Software and Programming Differences

PC-based control systems utilize standard operating systems and support high-level programming languages such as C++, Python, and Java, offering greater flexibility and easier integration with complex applications. PLCs rely on specialized ladder logic or structured text languages designed for deterministic real-time control, ensuring reliability and predictable performance in industrial environments. Software development for PC-based control often involves extensive debugging tools and graphical user interfaces, whereas PLC programming emphasizes simplicity, robustness, and compliance with IEC 61131-3 standards for automation tasks.

Scalability and Flexibility

PC-based control systems offer greater scalability and flexibility compared to traditional PLCs by leveraging advanced processing power and modular software architectures, enabling easy integration of complex control algorithms and real-time data analytics. PLCs excel in robust, deterministic operations with predefined I/O configurations, but scaling often requires hardware upgrades that can limit adaptability. The software-centric nature of PC-based controllers supports rapid reconfiguration and expansion, making them ideal for evolving industrial processes that demand dynamic control strategies.

Performance and Real-Time Capabilities

PLC systems are designed for high reliability and deterministic real-time control, offering fixed scan cycles and optimized interrupt handling to ensure predictable performance in industrial automation. PC-based control provides greater computational power and flexibility but may face latency and non-deterministic behavior due to general-purpose operating systems, affecting real-time responsiveness. Performance in PLCs excels in mission-critical, low-latency control tasks, while PC-based systems are suited for complex data processing and integration where real-time constraints are less stringent.

Integration and Connectivity

PC-based control systems offer enhanced integration and connectivity by leveraging standard communication protocols like Ethernet/IP, OPC UA, and MQTT, facilitating seamless data exchange across enterprise networks. Unlike traditional PLCs, PC-based controllers can easily integrate with IoT platforms, cloud services, and advanced analytics tools, enabling real-time monitoring and remote management. This connectivity advantage supports more flexible automation architectures and rapid scalability in Industry 4.0 environments.

Reliability and Maintenance

PC-based control systems offer enhanced flexibility and easier software updates compared to traditional PLCs but may face challenges in reliability due to susceptibility to operating system crashes and hardware failures. PLCs are designed for industrial environments with rugged hardware and real-time deterministic control, providing superior reliability and minimal downtime in critical applications. Maintenance of PLCs typically involves standardized modules and diagnostics, simplifying troubleshooting, while PC-based systems may require specialized IT knowledge for software and hardware maintenance, potentially increasing downtime risk.

Cost Analysis and ROI

PC-based control systems often offer lower initial hardware costs and greater flexibility compared to traditional PLCs, making them attractive for complex or scalable automation tasks. However, PLCs typically provide higher reliability, lower maintenance expenses, and longer operational lifespans, which can result in more favorable ROI for long-term, mission-critical applications. Evaluating total cost of ownership, including software licensing, integration, and downtime risk, is essential for an accurate cost analysis between PC-based control and PLC solutions.

Application Suitability and Industry Trends

PC-based control systems offer high flexibility and advanced data processing capabilities ideal for complex automation tasks and industries requiring real-time analytics, such as smart manufacturing and IoT integration. PLCs remain preferred in heavy industries like automotive and chemical plants due to their robustness, reliability, and real-time deterministic control under harsh environments. Industry trends show a growing hybrid approach, combining PLCs for crucial control functions with PC-based systems for enhanced monitoring and adaptive control, optimizing overall operational efficiency.

PLC, PC-based control Infographic

libterm.com

libterm.com