Worm gears provide smooth and quiet operation, ideal for applications requiring precise speed reduction and torque multiplication. Their unique design enables high load capacity and self-locking capabilities, preventing back driving in mechanical systems. Discover how worm gears can enhance your machinery by exploring the rest of this article.

Table of Comparison

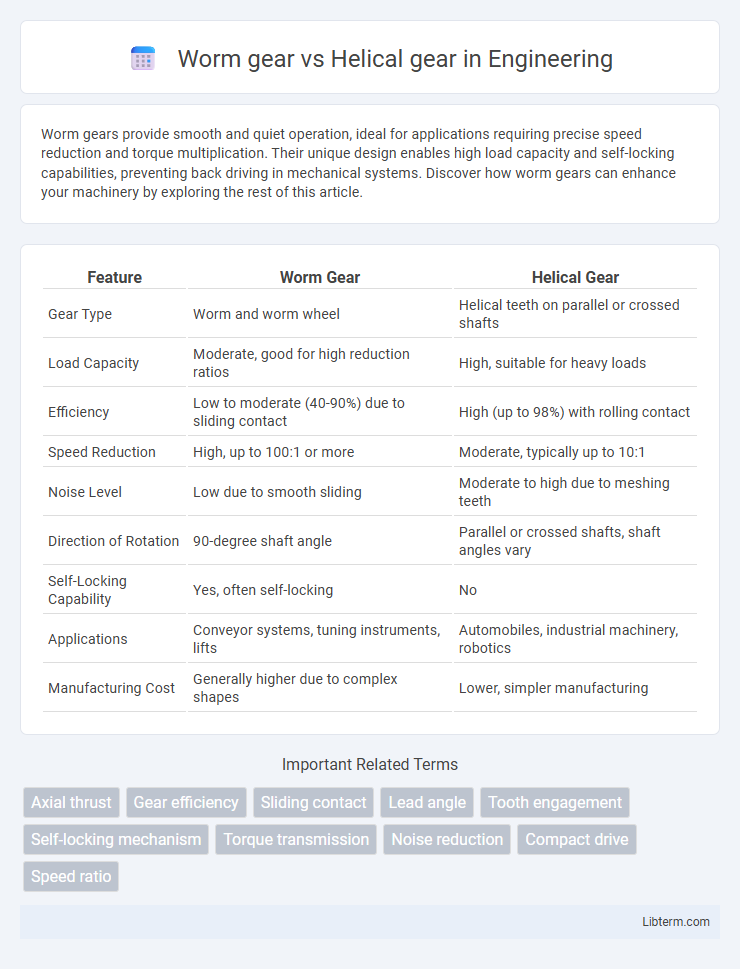

| Feature | Worm Gear | Helical Gear |

|---|---|---|

| Gear Type | Worm and worm wheel | Helical teeth on parallel or crossed shafts |

| Load Capacity | Moderate, good for high reduction ratios | High, suitable for heavy loads |

| Efficiency | Low to moderate (40-90%) due to sliding contact | High (up to 98%) with rolling contact |

| Speed Reduction | High, up to 100:1 or more | Moderate, typically up to 10:1 |

| Noise Level | Low due to smooth sliding | Moderate to high due to meshing teeth |

| Direction of Rotation | 90-degree shaft angle | Parallel or crossed shafts, shaft angles vary |

| Self-Locking Capability | Yes, often self-locking | No |

| Applications | Conveyor systems, tuning instruments, lifts | Automobiles, industrial machinery, robotics |

| Manufacturing Cost | Generally higher due to complex shapes | Lower, simpler manufacturing |

Introduction to Gear Mechanisms

Worm gears consist of a screw-like worm meshing with a worm wheel, providing high torque reduction and smooth, quiet operation ideal for heavy-load applications. Helical gears feature angled teeth that engage more gradually than spur gears, allowing for higher load capacity and efficiency with reduced noise and vibration in various mechanical systems. Both gear types serve distinct roles in power transmission, with worm gears offering compact design and worm locking capability, while helical gears excel in speed and torque conversion.

What Is a Worm Gear?

A worm gear consists of a screw-like worm meshing with a worm wheel to achieve high torque and significant speed reduction in compact spaces. This gear type is commonly used in applications requiring precise motion control and self-locking capabilities, such as conveyor systems and elevators. Unlike helical gears, worm gears operate with sliding contact, resulting in quieter operation but higher friction and heat generation.

What Is a Helical Gear?

A helical gear features angled teeth cut at a helix angle to the gear axis, allowing for smoother and quieter operation compared to straight-cut gears. Its design enables gradual tooth engagement and higher load capacity, making it ideal for high-speed applications and transmitting power between parallel or slightly crossed shafts. Unlike worm gears, helical gears offer greater efficiency and are commonly used in automotive transmissions and industrial machinery.

Key Differences Between Worm and Helical Gears

Worm gears feature a screw-like worm that meshes with a worm wheel, providing high torque and significant speed reduction in compact spaces, while helical gears have angled teeth that engage gradually, enabling smoother operation and higher load capacity. Worm gears typically offer non-reversible motion and lower efficiency, often around 40-50%, compared to helical gears which reach efficiencies up to 98% due to better tooth contact and reduced friction. The primary differences include their drive mechanisms, efficiency levels, load capacities, noise generation, and suitability for different applications such as worm gears in conveyors and tuning instruments, and helical gears in automotive transmissions and industrial machinery.

Efficiency Comparison: Worm vs Helical Gears

Helical gears typically exhibit higher efficiency, ranging from 94% to 99%, due to their rolling contact and lower friction compared to worm gears. Worm gears often have lower efficiency, between 40% and 90%, primarily because of the sliding action between the worm and the worm wheel that generates significant heat and energy loss. The efficiency gap makes helical gears preferable in applications requiring energy conservation and high-speed transmission, while worm gears are chosen for their compactness and high reduction ratios despite lower efficiency.

Torque and Load Capabilities

Worm gears provide high torque multiplication and can handle heavy loads at low speeds due to their unique sliding contact, making them ideal for applications requiring significant reduction ratios and self-locking capabilities. Helical gears offer smoother operation and higher load capacities at moderate to high speeds because their angled teeth engage gradually, distributing load more evenly and reducing noise. While worm gears excel in torque and axial load resistance, helical gears outperform in efficiency and load distribution under dynamic conditions.

Applications of Worm Gears

Worm gears are widely used in conveyor systems, elevators, and packaging machinery due to their high torque transmission and ability to provide significant speed reduction in compact spaces. Their self-locking characteristic makes them ideal for applications requiring reliable holding capabilities without backlash, such as in hoisting and lifting equipment. Unlike helical gears, worm gears offer smooth, quiet operation and precise control, making them suitable for specialized drives and automated positioning systems.

Applications of Helical Gears

Helical gears are widely used in automotive transmissions, conveyors, and industrial machinery due to their ability to handle high loads and operate smoothly at high speeds with minimal noise and vibration. Their angled teeth provide gradual engagement that enhances efficiency and reduces wear, making them ideal for applications requiring precise motion and durability. Compared to worm gears, helical gears offer higher torque transmission and better performance in parallel or crossed shaft configurations.

Maintenance and Durability Considerations

Worm gears demand frequent lubrication and careful alignment to prevent excessive wear due to their sliding contact, affecting maintenance schedules and overall durability. Helical gears offer greater durability with rolling contact that reduces friction and wear, resulting in less frequent maintenance and longer service life. Proper maintenance practices, including regular inspection for wear and timely lubrication, are essential for maximizing the lifespan of both worm and helical gears in industrial applications.

Choosing the Right Gear for Your Application

Worm gears provide high torque and smooth, quiet operation ideal for applications requiring substantial speed reduction and compact design. Helical gears offer greater load capacity and efficiency with quieter performance than spur gears, making them suitable for high-speed, heavy-load operations. Selecting the right gear depends on factors like torque demands, space constraints, noise tolerance, and efficiency requirements specific to your machinery.

Worm gear Infographic

libterm.com

libterm.com