Strength is the essential quality that empowers you to overcome challenges and achieve your goals with resilience. Building both physical and mental strength enhances performance, confidence, and overall well-being. Discover practical ways to cultivate your strength throughout the rest of this article.

Table of Comparison

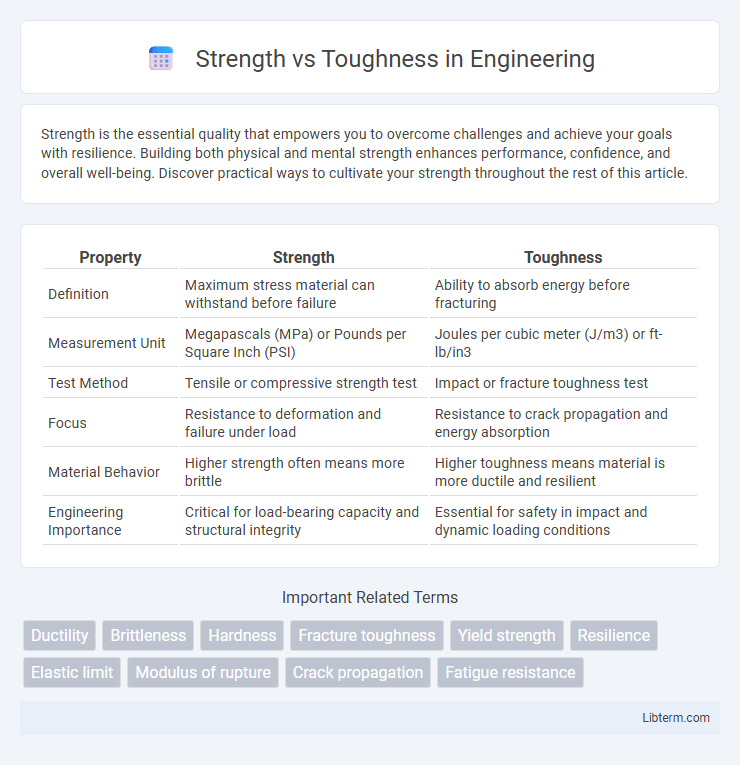

| Property | Strength | Toughness |

|---|---|---|

| Definition | Maximum stress material can withstand before failure | Ability to absorb energy before fracturing |

| Measurement Unit | Megapascals (MPa) or Pounds per Square Inch (PSI) | Joules per cubic meter (J/m3) or ft-lb/in3 |

| Test Method | Tensile or compressive strength test | Impact or fracture toughness test |

| Focus | Resistance to deformation and failure under load | Resistance to crack propagation and energy absorption |

| Material Behavior | Higher strength often means more brittle | Higher toughness means material is more ductile and resilient |

| Engineering Importance | Critical for load-bearing capacity and structural integrity | Essential for safety in impact and dynamic loading conditions |

Introduction to Strength and Toughness

Strength measures a material's ability to withstand applied loads without failure, typically quantified by metrics such as tensile strength and yield strength. Toughness reflects a material's capacity to absorb energy and deform plastically before fracturing, often assessed through impact resistance tests. Understanding both properties is essential for selecting materials that balance load-bearing capability with resistance to crack propagation in engineering applications.

Defining Strength: What Does It Mean?

Strength refers to a material's ability to withstand an applied load without failure or plastic deformation, commonly measured by parameters such as tensile strength, yield strength, and compressive strength. It defines how much stress a material can endure before it permanently changes shape or breaks. Understanding strength is crucial for selecting materials in engineering applications where resistance to force and structural integrity are paramount.

Understanding Toughness: Beyond Just Strength

Toughness measures a material's ability to absorb energy and deform plastically before fracturing, combining strength and ductility into one crucial property for impact resistance. Unlike strength, which focuses solely on the maximum stress a material can withstand without failure, toughness emphasizes durability under dynamic or sudden loads. Materials like tempered steel demonstrate high toughness by balancing strong atomic bonds with the capacity to bend without breaking, making toughness a vital consideration in safety-critical applications.

Key Differences Between Strength and Toughness

Strength refers to the maximum stress a material can withstand before failure, typically measured by tensile or compressive tests. Toughness indicates a material's ability to absorb energy and deform plastically without fracturing, often quantified by impact tests like the Charpy or Izod test. While strength emphasizes resistance to breaking under load, toughness highlights resistance to crack propagation and damage under dynamic or sudden forces.

Measuring Strength: Common Methods and Standards

Measuring strength involves standardized tests such as tensile, compressive, and shear strength assessments, which determine a material's capacity to withstand applied forces without failure. Common methods include the use of universal testing machines that apply controlled stress until the specimen breaks or deforms, providing quantifiable data like ultimate tensile strength (UTS) and yield strength. International standards such as ASTM E8 for tension testing and ISO 6892 ensure consistent, accurate evaluation of material strength across industries.

Evaluating Toughness: Tests and Parameters

Toughness is evaluated through impact and fracture toughness tests such as Charpy, Izod, and J-integral methods, which measure a material's ability to absorb energy before fracturing. Parameters including energy absorption, crack resistance, and fracture propagation rates provide quantitative data to assess toughness accurately. Unlike strength, toughness reflects both strength and ductility, making comprehensive testing essential for material selection in applications demanding high damage tolerance.

The Role of Microstructure in Strength and Toughness

Microstructure plays a crucial role in determining both strength and toughness in materials by influencing dislocation movement and crack propagation. Fine-grained microstructures typically enhance strength through grain boundary strengthening, while certain phase distributions and precipitates can improve toughness by absorbing impact energy and impeding crack growth. Optimizing microstructural characteristics such as grain size, phase composition, and precipitate morphology balances strength and toughness for superior material performance.

Applications Where Strength Matters Most

High strength materials excel in applications demanding resistance to deformation under heavy loads, such as aerospace components and structural beams in construction. These materials ensure safety and reliability in critical infrastructure by maintaining shape and integrity under extreme forces. Strength is paramount in scenarios where material failure could lead to catastrophic consequences, making it indispensable in automotive crash structures and pressure vessels.

Industries Prioritizing Toughness

Industries such as aerospace, automotive, and construction prioritize toughness over strength to ensure materials can absorb energy and resist fracture under impact or cyclic loading conditions. Toughness, measured by the material's ability to withstand stress and strain without failure, is critical for components exposed to dynamic forces and harsh environments. This focus enhances safety, durability, and longevity in applications where brittle failure could lead to catastrophic consequences.

Balancing Strength and Toughness in Material Design

Balancing strength and toughness in material design requires optimizing microstructure to enhance load-bearing capacity without sacrificing resistance to crack propagation. Advanced composite materials and alloy treatments enable tailored mechanical properties, achieving a synergy between high tensile strength and impact toughness. Engineers leverage computational modeling and experimental data to predict and fine-tune this balance, ensuring durability and performance in critical applications.

Strength Infographic

libterm.com

libterm.com