Thermodynamics explores the principles governing energy transfer and the behavior of heat within physical systems. Understanding concepts like entropy, enthalpy, and the laws of thermodynamics is crucial for applications ranging from engines to climate science. Discover how mastering thermodynamics can enhance your grasp of energy processes by reading the full article.

Table of Comparison

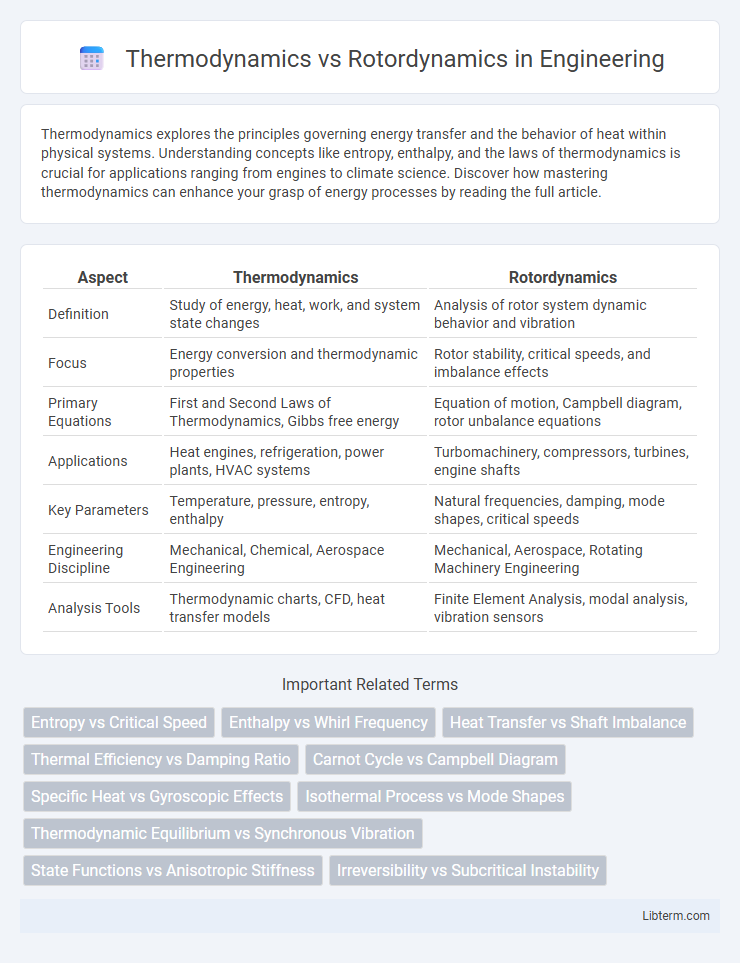

| Aspect | Thermodynamics | Rotordynamics |

|---|---|---|

| Definition | Study of energy, heat, work, and system state changes | Analysis of rotor system dynamic behavior and vibration |

| Focus | Energy conversion and thermodynamic properties | Rotor stability, critical speeds, and imbalance effects |

| Primary Equations | First and Second Laws of Thermodynamics, Gibbs free energy | Equation of motion, Campbell diagram, rotor unbalance equations |

| Applications | Heat engines, refrigeration, power plants, HVAC systems | Turbomachinery, compressors, turbines, engine shafts |

| Key Parameters | Temperature, pressure, entropy, enthalpy | Natural frequencies, damping, mode shapes, critical speeds |

| Engineering Discipline | Mechanical, Chemical, Aerospace Engineering | Mechanical, Aerospace, Rotating Machinery Engineering |

| Analysis Tools | Thermodynamic charts, CFD, heat transfer models | Finite Element Analysis, modal analysis, vibration sensors |

Introduction to Thermodynamics and Rotordynamics

Thermodynamics studies energy, heat transfer, and work in systems, emphasizing laws that govern energy conservation and entropy. Rotordynamics focuses on the behavior, vibration, and stability of rotating machinery components, analyzing forces and dynamic response in rotors. Understanding both fields is crucial for optimizing mechanical system performance and preventing failures in energy and rotating equipment applications.

Fundamental Principles of Thermodynamics

Thermodynamics is governed by the fundamental principles of energy conservation, entropy, and the laws describing heat, work, and energy transformations in physical systems. It focuses on macroscopic properties such as temperature, pressure, volume, and internal energy to analyze thermal processes and predict system behavior. Rotordynamics, in contrast, deals with the dynamic behavior of rotating machinery, emphasizing vibration, stability, and rotor-bearing interactions rather than thermodynamic properties.

Core Concepts of Rotordynamics

Rotordynamics centers on the dynamic behavior of rotating shafts and components, emphasizing vibration analysis, stability, and critical speeds to prevent mechanical failure. It involves studying gyroscopic effects, unbalance forces, and bearing dynamics to ensure system reliability under operational conditions. Thermodynamics, in contrast, deals with energy transfer and conversion processes, focusing on heat, work, and state properties rather than rotational mechanics.

Key Differences Between Thermodynamics and Rotordynamics

Thermodynamics studies energy transformations and heat transfer in systems, emphasizing laws governing temperature, pressure, and entropy changes, while rotordynamics analyzes the behavior of rotating machinery components, focusing on vibration, stability, and rotor dynamics. Key differences include thermodynamics addressing macroscopic energy equilibrium in fluids and solids, whereas rotordynamics concentrates on dynamic mechanical forces and rotor shaft behavior under rotational speeds. Thermodynamics applies broadly to engines, refrigerators, and power plants, whereas rotordynamics is critical in turbines, compressors, and rotating shaft design for predictive maintenance and failure prevention.

Applications of Thermodynamics in Engineering

Thermodynamics in engineering focuses on energy conversion processes critical for designing engines, power plants, and HVAC systems, ensuring efficient thermal management and performance optimization. Applications include analyzing heat transfer, fluid flow, and work interactions to improve system efficiency and sustainability. These principles support advancements in renewable energy technologies, environmental control, and mechanical system reliability.

Practical Uses of Rotordynamics in Industry

Rotordynamics plays a crucial role in industry by ensuring the stability and reliability of rotating machinery such as turbines, compressors, and pumps, preventing costly failures through vibration analysis and fault detection. Unlike thermodynamics, which focuses on energy conversion and heat transfer, rotordynamics specializes in the dynamic behavior of rotating shafts and components under operational conditions. Industries like power generation, aerospace, and manufacturing rely on rotordynamic principles to optimize machine performance, enhance safety, and extend equipment lifespan.

Mathematical Modeling in Thermodynamics vs Rotordynamics

Mathematical modeling in thermodynamics primarily involves the formulation of equations based on the laws of energy conservation, heat transfer, and state properties to predict system behavior under varying thermal conditions. Rotordynamics focuses on modeling the dynamic behavior of rotating machinery using differential equations that describe vibration, stability, and rotor-bearing interactions. Thermodynamic models emphasize scalar properties and energy balance, whereas rotordynamic models demand vectorial analysis of forces and motions, reflecting their distinct physical phenomena and mathematical complexities.

Challenges in Thermodynamic and Rotordynamic Analysis

Thermodynamic analysis faces challenges in accurately modeling complex heat transfer, phase changes, and fluid properties under varying temperature and pressure conditions, which require precise computational techniques and experimental validation. Rotordynamic analysis struggles with predicting rotor stability, vibration modes, and the effects of bearing dynamics and shaft misalignment, often necessitating advanced numerical simulations and real-time monitoring. Both fields demand high-fidelity modeling to address nonlinear interactions, material behavior, and system responses for reliable performance and safety assessments.

Interdisciplinary Connections and Overlaps

Thermodynamics and rotordynamics intersect significantly in the analysis of energy transfer and mechanical behavior in rotating machinery, where thermodynamic principles govern heat exchange and fluid flow impacting rotor performance. Concepts such as entropy, temperature gradients, and fluid viscosity from thermodynamics directly influence rotor stability, vibration, and critical speed in rotordynamics. Understanding this interdisciplinary overlap enhances predictive maintenance, efficiency optimization, and failure prevention in turbines, compressors, and pumps.

Future Trends in Thermodynamics and Rotordynamics

Future trends in thermodynamics emphasize the development of advanced materials and energy-efficient systems, including high-temperature superconductors and renewable energy integration to optimize thermal management. Rotordynamics is evolving through enhanced diagnostic techniques like real-time vibration analysis and AI-driven predictive maintenance, improving reliability and performance in rotating machinery. Both fields increasingly leverage computational modeling and machine learning to accelerate design innovation and operational efficiency in energy and mechanical systems.

Thermodynamics Infographic

libterm.com

libterm.com