Natural frequency refers to the specific rate at which an object or system vibrates when it is disturbed from its resting position without external forces acting on it. Understanding natural frequency is crucial in engineering and design to prevent resonant vibrations that could lead to structural failure or reduced performance. Discover how natural frequency affects various applications and how you can apply this knowledge by reading the rest of the article.

Table of Comparison

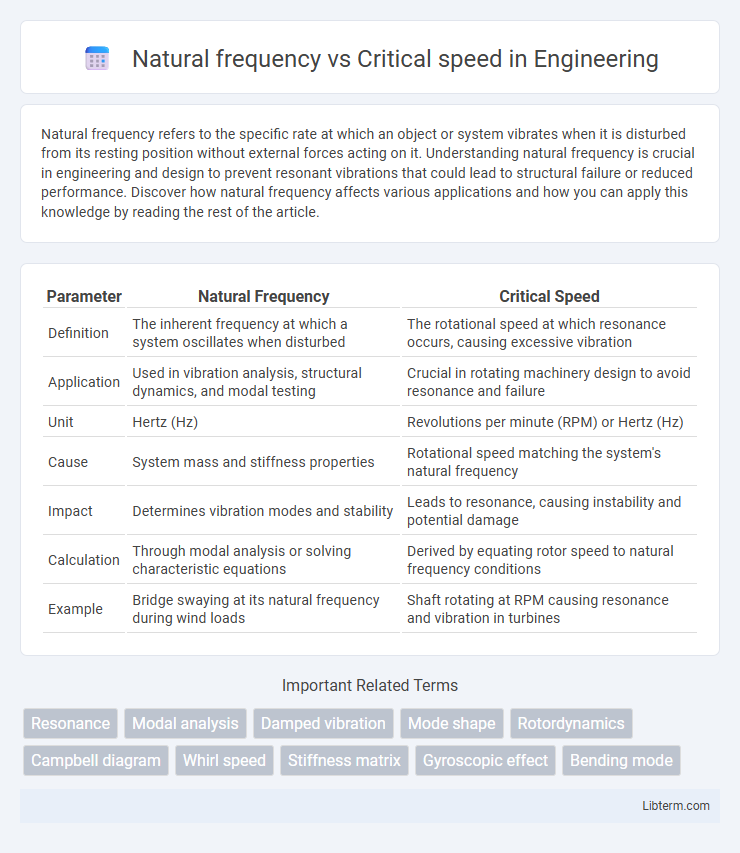

| Parameter | Natural Frequency | Critical Speed |

|---|---|---|

| Definition | The inherent frequency at which a system oscillates when disturbed | The rotational speed at which resonance occurs, causing excessive vibration |

| Application | Used in vibration analysis, structural dynamics, and modal testing | Crucial in rotating machinery design to avoid resonance and failure |

| Unit | Hertz (Hz) | Revolutions per minute (RPM) or Hertz (Hz) |

| Cause | System mass and stiffness properties | Rotational speed matching the system's natural frequency |

| Impact | Determines vibration modes and stability | Leads to resonance, causing instability and potential damage |

| Calculation | Through modal analysis or solving characteristic equations | Derived by equating rotor speed to natural frequency conditions |

| Example | Bridge swaying at its natural frequency during wind loads | Shaft rotating at RPM causing resonance and vibration in turbines |

Understanding Natural Frequency

Natural frequency refers to the rate at which a system oscillates when disturbed from its equilibrium position without external forces. It depends on the system's stiffness and mass, crucial for predicting resonant behavior in mechanical and structural components. Understanding natural frequency enables engineers to design systems that avoid resonance, preventing excessive vibrations and potential failure.

Defining Critical Speed

Critical speed is the rotational speed at which a rotating shaft or system experiences resonance due to its natural frequency, causing maximum vibration amplitude and potential structural failure. It occurs when the rotational speed matches the system's natural frequency, amplifying oscillations and leading to instability. Understanding critical speed is essential for safe machinery design to avoid resonance-induced damage and ensure reliable operation.

Key Differences Between Natural Frequency and Critical Speed

Natural frequency refers to the inherent vibration rate of a system when disturbed without external forces, while critical speed is the rotational speed at which excessive vibration occurs due to resonance in rotating machinery. Natural frequency is a property dependent on system mass and stiffness, whereas critical speed depends on the system's geometry, rotational inertia, and support conditions. Understanding the distinction is crucial for avoiding resonance-induced failures in mechanical design and operation.

Importance in Mechanical Systems

Natural frequency determines the specific vibration rate at which a mechanical system tends to oscillate when disturbed, crucial for avoiding resonance that can lead to excessive vibrations and structural failure. Critical speed is the rotational speed at which the system's natural frequency coincides with the excitation frequency, causing severe resonance and potential damage in rotating machinery like shafts, turbines, and engines. Understanding and controlling these parameters is essential for designing reliable mechanical systems, ensuring operational stability, and extending equipment lifespan.

Factors Influencing Natural Frequency

Natural frequency is primarily influenced by the system's stiffness and mass, with increased stiffness raising frequency and increased mass lowering it. Material properties, geometry, and boundary conditions further affect natural frequency by altering the system's dynamic response. In rotating machinery, variations in rotational speed and shaft flexibility can shift natural frequencies and approach critical speed, where resonance and potential failure may occur.

Factors Affecting Critical Speed

Critical speed is influenced by factors such as shaft stiffness, mass distribution, bearing support conditions, and rotational speed, which together determine the point at which resonance occurs. Natural frequency depends on the system's physical properties, including material elasticity, geometry, and boundary conditions, and represents the inherent oscillation rate without external forces. Understanding these factors is essential for preventing excessive vibrations and ensuring mechanical stability in rotating machinery.

Real-World Examples and Case Studies

Natural frequency refers to the inherent vibration rate of a system when disturbed, while critical speed is the rotational speed at which resonance causes excessive vibrations. Real-world examples include turbine blades in power plants, where operating near the natural frequency leads to critical speed issues causing structural fatigue and potential failure. Case studies in railroad engineering highlight how wheel-axle assemblies experience critical speeds that must be avoided to prevent derailments and maintain safety standards.

Vibration Problems Due to Resonance

Natural frequency is the inherent rate at which a system oscillates when disturbed, while critical speed is the specific rotational speed at which resonance occurs, causing excessive vibration. Resonance arises when the operational speed matches the natural frequency, amplifying vibration amplitudes and leading to potential structural damage or failure. Understanding and controlling natural frequency and critical speed are essential in machinery design to prevent vibration problems and ensure operational stability.

Methods to Measure and Analyze

Natural frequency is measured using modal analysis techniques such as impact hammer tests or shaker excitation, capturing vibration response data via accelerometers to identify resonance peaks. Critical speed, particularly in rotating machinery, is determined through spin tests or computational methods like finite element analysis (FEA) that predict the speed at which resonance occurs, leading to excessive vibration. Advanced tools such as laser vibrometry and spectrum analyzers enhance the precision in detecting both natural frequency and critical speed, enabling effective diagnostic and preventive maintenance strategies.

Engineering Solutions for Safe Operation

Natural frequency refers to the inherent vibration rate of a system when disturbed, while critical speed is the rotational speed at which resonance occurs, causing excessive vibration and potential failure. Engineering solutions for safe operation include designing shafts and rotors to operate below critical speeds, using damping materials, and performing dynamic balancing to mitigate resonance effects. Implementing finite element analysis and vibration monitoring systems ensures structural integrity and prolongs equipment lifespan under varying operational conditions.

Natural frequency Infographic

libterm.com

libterm.com