A pilot drill is a small-diameter hole drilled initially to guide the larger drill bit accurately and prevent it from wandering during the drilling process. This technique enhances precision and reduces the risk of damaging the workpiece, especially in metalworking or woodworking projects. Discover more about how using a pilot drill can improve your drilling accuracy in the rest of this article.

Table of Comparison

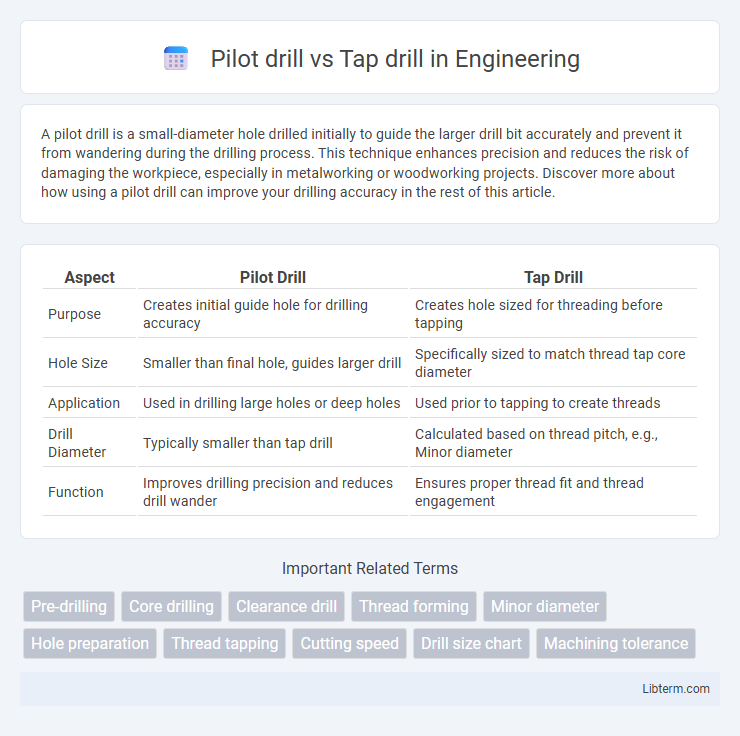

| Aspect | Pilot Drill | Tap Drill |

|---|---|---|

| Purpose | Creates initial guide hole for drilling accuracy | Creates hole sized for threading before tapping |

| Hole Size | Smaller than final hole, guides larger drill | Specifically sized to match thread tap core diameter |

| Application | Used in drilling large holes or deep holes | Used prior to tapping to create threads |

| Drill Diameter | Typically smaller than tap drill | Calculated based on thread pitch, e.g., Minor diameter |

| Function | Improves drilling precision and reduces drill wander | Ensures proper thread fit and thread engagement |

Introduction to Pilot Drill and Tap Drill

Pilot drill is the initial drill bit used to create a small, precise hole that guides the larger drill or tap, ensuring accuracy and preventing bit wandering. Tap drill refers to the drill size used to create the correct hole diameter that matches the tap's thread pitch, allowing proper thread formation without damaging the material. Selecting the appropriate pilot and tap drills is crucial for efficient threading and maintaining the strength and integrity of the threaded hole.

What is a Pilot Drill?

A pilot drill is a smaller diameter drill bit used to create an initial hole that guides a larger tap drill in metalworking or woodworking. It ensures accurate hole positioning and reduces the risk of material damage during threading operations. Compared to a tap drill, the pilot drill provides precise entry points, improving overall thread quality and alignment.

What is a Tap Drill?

A tap drill is the specific hole size drilled before tapping threads into a material, ensuring the correct thread engagement and strength. It is typically smaller than the final screw size to allow for proper thread formation during tapping. Selecting the accurate tap drill diameter is critical for precision threading and maintaining structural integrity in metalworking and manufacturing processes.

Key Differences Between Pilot Drill and Tap Drill

Pilot drill creates a small guide hole to position the larger drill bit accurately, while tap drill determines the hole size for threading. The pilot drill is usually smaller and ensures proper alignment, whereas the tap drill size is calculated based on the thread pitch to achieve the correct internal thread fit. Selecting the appropriate pilot and tap drill affects machining precision and thread quality in metalworking.

Applications of Pilot Drill vs Tap Drill

Pilot drills are primarily used to create precise starter holes in materials, ensuring accurate guidance for larger drill bits or taps. Tap drills, on the other hand, are specifically sized to create holes that accommodate threading tools, allowing for the creation of internal screw threads with the correct depth and diameter. In manufacturing and metalworking, using a pilot drill improves alignment and reduces material stress before tapping, while selecting the appropriate tap drill size is crucial for achieving strong, properly threaded holes for fasteners.

Drill Size Selection for Tapping

Selecting the correct drill size for tapping involves choosing a tap drill that matches the desired thread engagement, typically calculated by subtracting the pitch from the major diameter of the screw thread. A pilot drill, generally smaller than the tap drill, is used to create an initial guidance hole ensuring precise alignment but does not account for the thread depth required. Proper drill size selection based on tap drill standards ensures optimal thread strength and avoids excessive material removal or thread stripping.

Importance of Accuracy in Pilot and Tap Drilling

Accuracy in pilot and tap drilling is crucial for ensuring precise hole placement and proper thread engagement, directly impacting the quality and integrity of the final assembly. Pilot drills establish the initial hole size and alignment, serving as a guide for subsequent drilling processes, while tap drills determine the thread size and pitch, affecting the strength of threaded connections. Precise control during both pilot and tap drilling minimizes material wastage, reduces tool wear, and ensures consistent performance in manufacturing and mechanical applications.

Common Mistakes and How to Avoid Them

Using an incorrect pilot drill size often leads to misaligned holes and poor thread quality, while selecting the wrong tap drill diameter can result in weak threads or tap breakage. Overlooking the proper clearance and drill type causes excessive wear on the tap and uneven thread profiles. To avoid these mistakes, always consult precise drill charts and verify material specifications to ensure optimal drill-tap compatibility and thread integrity.

Tools and Materials Required

Pilot drills require a smaller diameter drill bit to create an initial guide hole, typically used before tapping to ensure precision and reduce tool wear. Tap drills demand specific drill bits matched to the tap size and thread pitch, often made from high-speed steel or cobalt for durability in threading applications. Both tools require stable materials, such as hardened steel or aluminum, suitable for accurate hole preparation and thread cutting in manufacturing and metalworking processes.

Tips for Efficient Drilling and Tapping

Selecting the correct pilot drill size ensures accurate hole alignment and reduces material stress before using the tap drill to create threads. Using a pilot drill with a sharp, pointed tip enhances stability and prevents drill wandering, while choosing the appropriate tap drill diameter maximizes thread strength and minimizes tap breakage. Proper lubrication and controlled feed rates during tapping improve tool life and produce clean, precise threads, optimizing overall drilling and tapping efficiency.

Pilot drill Infographic

libterm.com

libterm.com