O-rings provide a reliable seal in various mechanical systems, preventing leaks and ensuring optimal performance under pressure. Crafted from durable materials like silicone, nitrile, or fluorocarbon, they maintain flexibility and resilience in diverse environments. Explore the article to understand how choosing the right O-ring can enhance your equipment's efficiency and longevity.

Table of Comparison

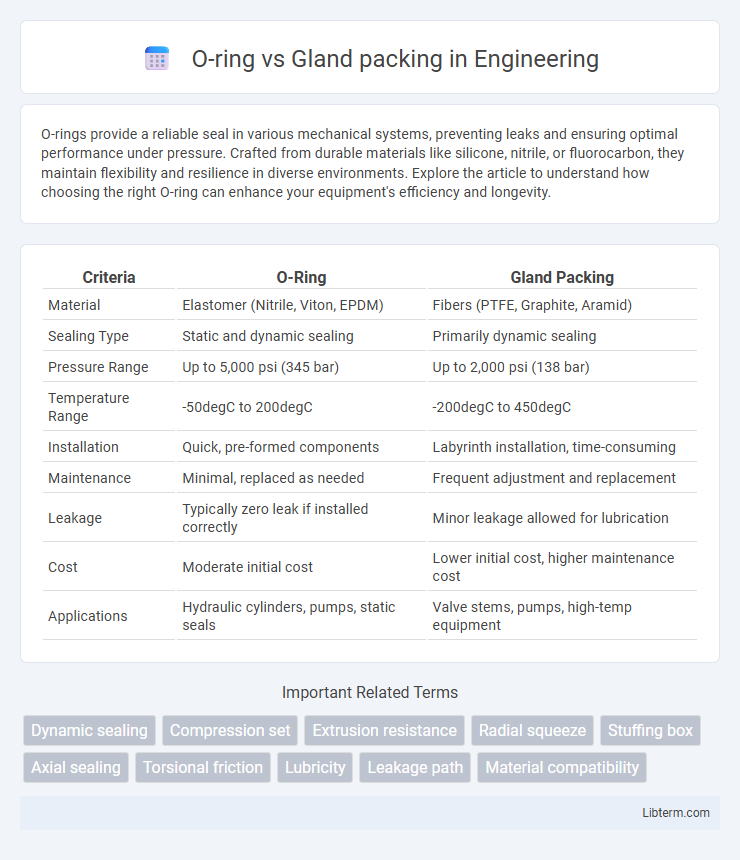

| Criteria | O-Ring | Gland Packing |

|---|---|---|

| Material | Elastomer (Nitrile, Viton, EPDM) | Fibers (PTFE, Graphite, Aramid) |

| Sealing Type | Static and dynamic sealing | Primarily dynamic sealing |

| Pressure Range | Up to 5,000 psi (345 bar) | Up to 2,000 psi (138 bar) |

| Temperature Range | -50degC to 200degC | -200degC to 450degC |

| Installation | Quick, pre-formed components | Labyrinth installation, time-consuming |

| Maintenance | Minimal, replaced as needed | Frequent adjustment and replacement |

| Leakage | Typically zero leak if installed correctly | Minor leakage allowed for lubrication |

| Cost | Moderate initial cost | Lower initial cost, higher maintenance cost |

| Applications | Hydraulic cylinders, pumps, static seals | Valve stems, pumps, high-temp equipment |

Introduction to Sealing Technologies

O-ring and gland packing are essential sealing technologies used to prevent fluid leakage in mechanical systems. O-rings provide reliable sealing through elastic deformation, ideal for dynamic and static applications under various pressure and temperature conditions. Gland packing, made from braided fibers or synthetic materials, offers versatile sealing solutions for rotating or reciprocating shafts, especially in high-pressure environments where lubrication is required.

Understanding O-Rings: Structure and Function

O-rings are circular elastomeric seals with a round cross-section designed to fit into a gland groove, creating a secure seal between two or more parts by compressing under pressure, preventing fluid or gas leakage. Their simple structure allows for efficient sealing in static and dynamic applications across various industries, including automotive, aerospace, and hydraulics. Unlike gland packing, O-rings provide a more compact, reliable seal with superior resistance to wear and pressure fluctuations, reducing maintenance needs and increasing equipment longevity.

Overview of Gland Packing: Composition and Applications

Gland packing consists of braided or woven fibers such as graphite, PTFE, aramid, or cotton, often impregnated with lubricants or resins to enhance sealing performance and durability. It is widely used in dynamic sealing applications like pumps, valves, and mixers where rotational or reciprocating motion occurs. The material's flexibility and resilience make gland packing suitable for high-pressure, high-temperature environments, providing a reliable seal against fluid leakage.

Key Differences Between O-Ring and Gland Packing

O-rings provide a reliable, uniform seal with easy installation and low maintenance, commonly made from elastomeric materials suitable for static or dynamic applications. Gland packing, composed of braided fibers or PTFE, is designed for sealing reciprocating or rotating shafts under high pressure but requires periodic tightening and maintenance. Key differences include sealing efficiency, maintenance requirements, and suitability for specific operating conditions, with O-rings offering superior leak prevention and gland packing excelling in heavy-duty, high-temperature environments.

Performance Comparison: Sealing Integrity

O-rings provide superior sealing integrity due to their elastomeric properties, enabling consistent compression and resistance to fluid leakage under varied pressure and temperature conditions. Gland packing, composed of braided fibers, offers less reliable sealing performance, often requiring frequent adjustments and maintenance to prevent leakage in dynamic applications. The elastomeric deformation of O-rings creates a tighter, more durable seal compared to the mechanical compression and potential wear of gland packing materials.

Installation Procedures: O-Ring vs Gland Packing

O-ring installation requires precise groove dimensioning and careful lubrication to ensure a proper seal and avoid damage during assembly. Gland packing installation involves layering braided or woven packing material into the stuffing box, compressing it with a gland follower to adjust the seal tightness and prevent leakage. Both methods demand attention to compatibility with operating pressures and temperatures to maintain seal effectiveness.

Maintenance and Longevity Considerations

O-rings require less frequent maintenance due to their simple installation and minimal wear if properly lubricated and installed, offering extended longevity in static sealing applications. Gland packing demands regular inspection and adjustment to prevent leaks and wear, as improper packing compression can lead to faster degradation and equipment damage. Selecting the correct material and ensuring appropriate maintenance schedules are critical for maximizing the lifespan of both sealing methods.

Suitability for Different Industrial Applications

O-rings provide superior sealing in static and dynamic applications involving liquids and gases, making them ideal for automotive engines, hydraulic systems, and aerospace components due to their durability and resistance to pressure variations. Gland packing excels in heavy-duty industrial environments such as pumps and valves where frequent maintenance and high-temperature tolerance are required, particularly in chemical plants and refineries. Selection depends on factors like pressure, temperature, fluid compatibility, and maintenance frequency specific to industries like oil and gas, manufacturing, and power generation.

Cost Analysis: O-Ring vs Gland Packing

O-rings generally offer a lower initial cost and simpler installation compared to gland packing, which often requires regular maintenance and replacement, increasing long-term expenses. Gland packing may incur higher operational costs due to potential leakage and the need for frequent adjustments to maintain sealing efficiency. Considering lifecycle costs, O-rings tend to provide better cost-effectiveness in applications demanding reliable, low-maintenance sealing solutions.

Choosing the Right Sealing Solution

Selecting the right sealing solution between O-ring and gland packing depends on application requirements such as pressure, temperature, and fluid type. O-rings provide reliable, low-maintenance sealing for static or dynamic interfaces with high resistance to chemicals and wear. Gland packing suits heavy-duty, rotating or reciprocating shafts in environments with higher temperature and pressure, offering easier onsite maintenance despite increased friction and wear.

O-ring Infographic

libterm.com

libterm.com