Traditional manufacturing relies on established methods like assembly lines and manual labor to produce goods with consistent quality. This approach often emphasizes durability, precision, and controlled processes to meet industry standards and customer expectations. Explore the rest of the article to understand how these time-tested techniques continue to shape modern production and impact your business.

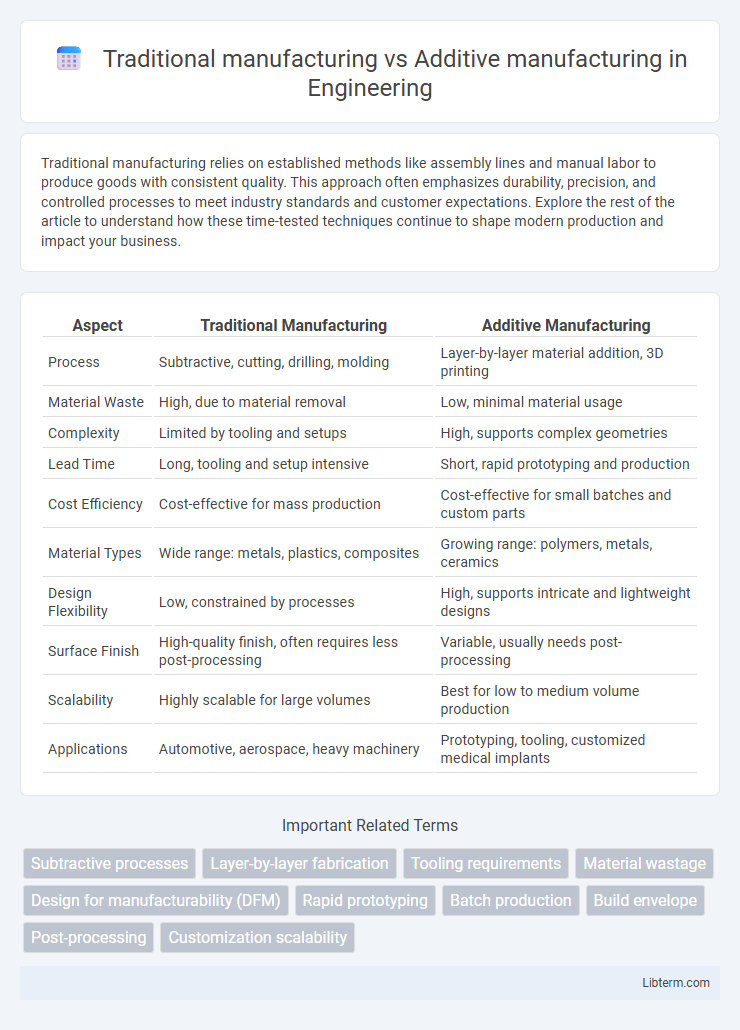

Table of Comparison

| Aspect | Traditional Manufacturing | Additive Manufacturing |

|---|---|---|

| Process | Subtractive, cutting, drilling, molding | Layer-by-layer material addition, 3D printing |

| Material Waste | High, due to material removal | Low, minimal material usage |

| Complexity | Limited by tooling and setups | High, supports complex geometries |

| Lead Time | Long, tooling and setup intensive | Short, rapid prototyping and production |

| Cost Efficiency | Cost-effective for mass production | Cost-effective for small batches and custom parts |

| Material Types | Wide range: metals, plastics, composites | Growing range: polymers, metals, ceramics |

| Design Flexibility | Low, constrained by processes | High, supports intricate and lightweight designs |

| Surface Finish | High-quality finish, often requires less post-processing | Variable, usually needs post-processing |

| Scalability | Highly scalable for large volumes | Best for low to medium volume production |

| Applications | Automotive, aerospace, heavy machinery | Prototyping, tooling, customized medical implants |

Understanding Traditional Manufacturing

Traditional manufacturing relies on subtractive processes such as milling, turning, and casting to shape raw materials into final products, often requiring extensive tooling and setup time. It excels in producing high volumes of consistent parts with established supply chains and lower per-unit costs for mass production. Understanding traditional manufacturing helps highlight its limitations in design flexibility and material waste compared to additive manufacturing techniques.

Overview of Additive Manufacturing

Additive manufacturing, also known as 3D printing, builds objects layer by layer using digital models, enabling complex geometries and customized designs unattainable with traditional subtractive methods. This technology reduces material waste by using only necessary materials, improves prototyping speed, and allows on-demand production, cutting inventory costs. Industries such as aerospace, healthcare, and automotive increasingly adopt additive manufacturing for its precision, flexibility, and ability to integrate lightweight structures and intricate internal features.

Process Differences: Subtractive vs Additive

Traditional manufacturing relies on subtractive processes, where material is removed from a solid block through cutting, drilling, or milling to create the final product. Additive manufacturing builds objects layer by layer by depositing material, typically using 3D printing technologies, enabling complex geometries and reduced waste. The subtractive approach is limited by tool access and material waste, whereas additive manufacturing offers design flexibility and material efficiency.

Material Utilization and Waste Reduction

Traditional manufacturing often involves subtractive processes that remove material from a larger block, resulting in significant waste and lower material utilization efficiency. Additive manufacturing builds components layer by layer, optimizing material usage and minimizing excess by only depositing necessary amounts. This precision in additive processes leads to substantial waste reduction and promotes sustainable production practices.

Production Speed and Flexibility

Traditional manufacturing relies on established processes like machining and molding, offering high production speed for large volumes but limited flexibility in design changes. Additive manufacturing, or 3D printing, provides unparalleled flexibility to create complex geometries and customize products quickly, though its production speed is generally slower for mass production compared to conventional methods. Industries balancing production speed and customization often integrate both techniques to optimize efficiency and adaptability.

Cost Comparison: Initial Investment and Scalability

Traditional manufacturing requires a high initial investment due to expensive tooling, molds, and setup costs, making it cost-effective primarily at large production volumes. Additive manufacturing features lower upfront costs with no need for specialized tooling, enabling affordable prototyping and small-batch production, but unit costs can increase with scale. Scalability favors traditional methods for mass production while additive manufacturing excels in flexible, low-volume, or customized manufacturing scenarios.

Design Complexity and Customization

Traditional manufacturing relies on subtractive processes and fixed tooling, limiting design complexity and customization due to high setup costs and longer lead times. Additive manufacturing enables the production of intricate geometries and highly customized parts by building layer-by-layer without the constraints of molds or dies. This flexibility supports rapid prototyping and personalized production, reducing material waste and enhancing design innovation.

Quality Control and Consistency

Traditional manufacturing relies on established quality control protocols involving statistical process control and consistent material properties to ensure uniformity across large production runs. Additive manufacturing introduces challenges in quality control due to layer-by-layer fabrication, which can cause variability in surface finish and mechanical properties, requiring advanced in-situ monitoring and real-time process adjustments. Consistency in additive manufacturing is improving with the integration of sensor technologies and AI-driven defect detection, but still lags behind the repeatability achieved in traditional manufacturing processes.

Environmental Impact and Sustainability

Traditional manufacturing generates significant waste and consumes high energy due to subtractive processes and material inefficiencies, leading to increased carbon emissions and environmental degradation. Additive manufacturing reduces material waste by building parts layer-by-layer, enabling lightweight designs that improve fuel efficiency and minimize resource consumption. The sustainability advantages of additive methods support circular economy principles through material recycling and on-demand production, reducing transportation emissions and inventory excess.

Future Trends in Manufacturing Technologies

Future trends in manufacturing technologies emphasize the integration of additive manufacturing (3D printing) with traditional manufacturing techniques to enhance customization, reduce material waste, and shorten production cycles. Advanced materials like metal alloys and composites in additive manufacturing are expanding capabilities, enabling complex geometries unattainable by conventional methods. Smart factories leveraging AI, IoT, and digital twins will increasingly unify additive and traditional manufacturing to optimize efficiency and responsiveness in production processes.

Traditional manufacturing Infographic

libterm.com

libterm.com