Brushless systems offer superior efficiency and reduced maintenance compared to traditional brushed motors by eliminating physical brushes and commutators. Their enhanced durability and quieter operation make them ideal for high-performance applications in industries like robotics, electric vehicles, and aerospace. Explore the rest of the article to understand how integrating brushless systems can optimize your projects and drive innovation.

Table of Comparison

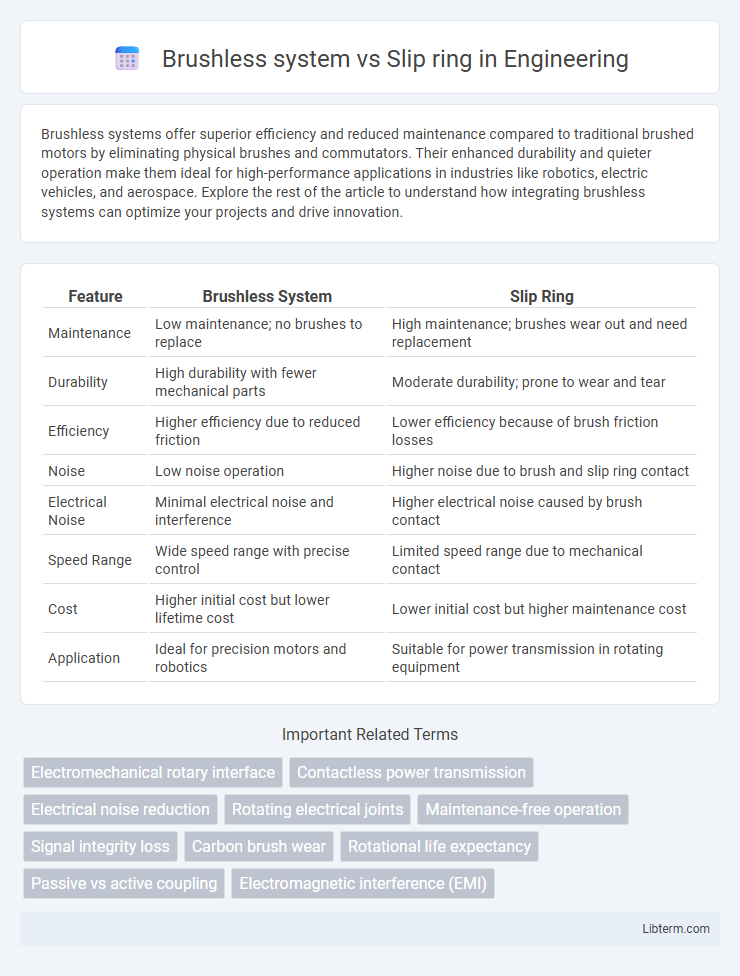

| Feature | Brushless System | Slip Ring |

|---|---|---|

| Maintenance | Low maintenance; no brushes to replace | High maintenance; brushes wear out and need replacement |

| Durability | High durability with fewer mechanical parts | Moderate durability; prone to wear and tear |

| Efficiency | Higher efficiency due to reduced friction | Lower efficiency because of brush friction losses |

| Noise | Low noise operation | Higher noise due to brush and slip ring contact |

| Electrical Noise | Minimal electrical noise and interference | Higher electrical noise caused by brush contact |

| Speed Range | Wide speed range with precise control | Limited speed range due to mechanical contact |

| Cost | Higher initial cost but lower lifetime cost | Lower initial cost but higher maintenance cost |

| Application | Ideal for precision motors and robotics | Suitable for power transmission in rotating equipment |

Introduction to Brushless and Slip Ring Systems

Brushless systems utilize electronically controlled motors that eliminate the need for physical brushes, resulting in higher efficiency, reduced maintenance, and enhanced reliability in industrial applications. Slip ring systems, on the other hand, employ rotating electrical contacts to transfer power and signals between stationary and rotating components, enabling continuous rotation without tangling wires. Understanding the fundamental differences between brushless and slip ring technologies is essential for selecting the appropriate solution based on torque requirements, speed, and operational environment.

Core Differences Between Brushless and Slip Ring Technologies

Brushless systems utilize permanent magnets and electronic commutation to eliminate physical contact, resulting in reduced maintenance and higher efficiency compared to slip ring technologies. Slip ring systems rely on conductive rings and brushes to transfer electrical signals or power, which introduces wear and potential signal noise over time. The core difference lies in the contactless operation of brushless systems versus the mechanical contact inherent in slip ring designs, impacting durability and reliability.

Key Applications of Brushless Systems

Brushless systems are widely used in electric vehicles, robotics, and aerospace due to their high efficiency, low maintenance, and precise control capabilities. Unlike slip ring systems, brushless motors eliminate wear and electrical noise, making them ideal for applications requiring long service life and reliability, such as drones, medical devices, and industrial automation. The absence of brushes and slip rings enhances performance in harsh environments, contributing to the growing adoption of brushless technology in advanced manufacturing and renewable energy sectors.

Common Uses for Slip Ring Systems

Slip ring systems are commonly used in applications requiring continuous rotation with electrical power and signal transmission, such as wind turbines, radar antennas, and industrial machinery. They enable seamless transfer of power and data across rotating interfaces, supporting high-speed rotation and complex signals. Their versatility in handling multiple circuits simultaneously makes them ideal for sectors like aerospace, robotics, and medical imaging equipment.

Efficiency Comparison: Brushless vs Slip Ring

Brushless systems offer higher efficiency than slip ring systems due to reduced friction and electrical losses, as they eliminate the physical contact between moving parts. Brushless motors achieve efficiency levels up to 90-95%, whereas slip ring motors typically range between 80-85% efficiency, influenced by brush wear and contact resistance. This efficiency advantage in brushless systems results in lower maintenance costs and improved energy savings in industrial applications.

Maintenance Requirements: Brushless vs Slip Ring

Brushless systems require significantly less maintenance compared to slip ring systems due to the absence of physical contact components that wear over time. Slip ring systems demand regular inspection, cleaning, and replacement of brushes and rings to prevent electrical noise and mechanical failure. The reduced maintenance needs of brushless systems enhance reliability and operational efficiency in industrial applications.

Reliability and Lifespan Analysis

Brushless systems offer superior reliability and extended lifespan compared to slip ring systems due to the absence of physical contact and reduced wear components. Slip ring systems experience mechanical wear from continuous friction between brushes and rings, leading to frequent maintenance and shorter operational life. Advanced brushless technology minimizes failure points and ensures consistent performance in demanding industrial applications.

Cost Implications: Initial Investment and Long-Term Savings

Brushless systems typically require a higher initial investment due to advanced materials and technology, but offer significant long-term savings by reducing maintenance costs and extending equipment lifespan. Slip ring systems involve lower upfront costs but incur ongoing expenses from wear and frequent replacements of brushes and rings. Choosing brushless technology maximizes efficiency and minimizes downtime, providing superior cost-effectiveness over the system's lifetime.

Suitability for Industrial and Commercial Applications

Brushless systems offer superior reliability and reduced maintenance due to the absence of physical contact components, making them highly suitable for continuous industrial operations and commercial machinery where uptime is critical. Slip ring systems, while effective in transmitting electrical signals and power through rotating interfaces, are better suited for applications with lower maintenance tolerance and where occasional servicing is feasible. Industrial environments demanding high durability and minimal downtime typically favor brushless systems for their long lifespan and enhanced efficiency.

Choosing the Right System: Factors to Consider

Choosing the right system between brushless and slip ring depends on factors such as maintenance requirements, operational speed, and environmental conditions. Brushless systems offer lower maintenance and longer lifespan due to the absence of physical contact, making them ideal for high-speed and clean environments. Slip ring systems, while requiring more upkeep, provide reliable electrical connection in applications needing continuous rotation with multiple signal types.

Brushless system Infographic

libterm.com

libterm.com