A timing belt is a crucial component in your vehicle's engine that synchronizes the rotation of the crankshaft and camshaft, ensuring valves open and close at the right time during the engine cycle. Failing to replace a worn or damaged timing belt can lead to severe engine damage and costly repairs. Discover everything you need to know about maintaining and replacing your timing belt in the rest of this article.

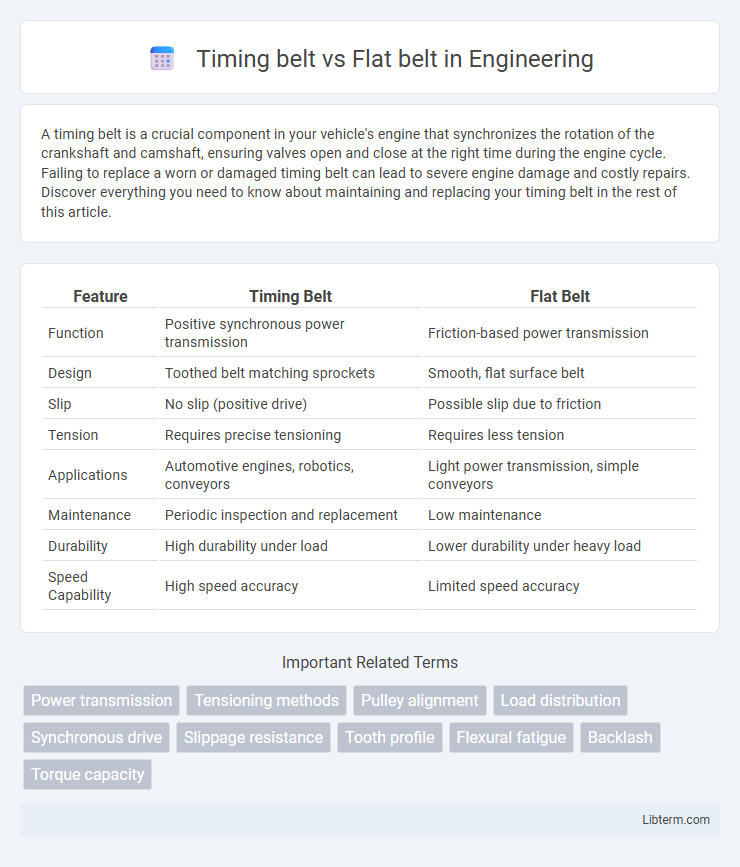

Table of Comparison

| Feature | Timing Belt | Flat Belt |

|---|---|---|

| Function | Positive synchronous power transmission | Friction-based power transmission |

| Design | Toothed belt matching sprockets | Smooth, flat surface belt |

| Slip | No slip (positive drive) | Possible slip due to friction |

| Tension | Requires precise tensioning | Requires less tension |

| Applications | Automotive engines, robotics, conveyors | Light power transmission, simple conveyors |

| Maintenance | Periodic inspection and replacement | Low maintenance |

| Durability | High durability under load | Lower durability under heavy load |

| Speed Capability | High speed accuracy | Limited speed accuracy |

Introduction to Timing Belt and Flat Belt

Timing belts feature toothed profiles that engage precisely with pulley grooves, ensuring synchronous motion and preventing slippage in mechanical systems. Flat belts consist of a smooth, continuous loop that transfers power through friction on flat pulleys, suitable for high-speed, low-torque applications. Timing belts excel in maintaining consistent speed ratios, while flat belts provide quieter operation and simpler installation.

Key Differences Between Timing Belts and Flat Belts

Timing belts feature teeth that mesh with pulley grooves, providing precise synchronization and preventing slippage, ideal for applications requiring accurate timing such as in automotive engines. Flat belts rely on friction between the belt and pulley surfaces, offering smooth, quiet operation and flexibility in power transmission over longer distances but are prone to slippage under high load. Timing belts require less maintenance and have a longer lifespan in high-torque environments, whereas flat belts are simpler, cost-effective, and better suited for light to moderate load conveyor systems.

Applications of Timing Belts

Timing belts are widely used in automotive engines, robotics, and conveyor systems where precise synchronization between rotating components is crucial. Their toothed design prevents slippage, making them ideal for applications requiring accurate timing, such as camshaft drives and 3D printers. High-performance machinery in manufacturing and printing industries frequently relies on timing belts for reliable motion control and durability under varying loads.

Common Uses for Flat Belts

Flat belts are commonly used in applications requiring smooth and quiet operation, such as in textile machinery, paper mills, and conveyor systems for light to moderate loads. Their flexibility and ease of alignment make them ideal for long-distance power transmission and where high speeds and low belt tension are needed. Flat belts are preferred in industries prioritizing energy efficiency and minimal maintenance over high torque transmission.

Performance and Efficiency Comparison

Timing belts provide superior performance in precision-driven applications due to their synchronous operation, which eliminates slippage and ensures consistent power transmission. Flat belts offer higher efficiency in high-speed, low-torque environments by minimizing friction losses and allowing for smoother operation over longer distances. The choice between timing and flat belts depends on the specific requirements for torque transmission, load capacity, and speed consistency in mechanical systems.

Durability and Maintenance Requirements

Timing belts offer superior durability due to their toothed design, which prevents slippage and reduces wear, making them ideal for precise mechanical applications. Flat belts require more frequent maintenance as they are prone to slipping and stretching, leading to faster wear and misalignment. Proper tensioning and periodic inspection are essential for both belt types, but timing belts typically demand less maintenance over time.

Cost Analysis: Timing Belt vs Flat Belt

Timing belts generally have higher initial costs compared to flat belts due to their precise tooth profiles and materials, which enhance durability and reduce slippage. Flat belts are more economical upfront but may incur higher maintenance and replacement expenses over time because of increased wear and the need for frequent tension adjustments. Evaluating long-term cost-effectiveness depends on application-specific factors like load, speed, and required belt longevity.

Factors to Consider When Choosing a Belt

When choosing between a timing belt and a flat belt, consider load capacity, speed, and precision requirements. Timing belts provide positive engagement and synchronization, ideal for high-precision applications and preventing slippage. Flat belts offer smoother, quieter operation and flexibility, suitable for low-tension, high-speed scenarios with less need for exact timing.

Advantages and Disadvantages of Each Type

Timing belts offer precise synchronization and high efficiency, making them ideal for applications requiring accurate timing such as automotive engines and robotics, but they tend to be more expensive and require exact tensioning. Flat belts provide smooth operation with less vibration, are cost-effective, and handle high-speed applications well, though they can slip under heavy load and necessitate larger pulleys to maintain grip. Selecting between timing and flat belts depends on balancing precision, load capacity, speed, and maintenance needs specific to the mechanical system.

Conclusion: Selecting the Right Belt for Your Needs

Choosing the right belt depends on application requirements such as load capacity, speed, and precision. Timing belts offer precise synchronization and minimal slippage, ideal for automotive engines and machinery requiring accurate timing. Flat belts provide smoother, quieter operation and are suited for high-speed, low-torque applications like conveyors and light industrial equipment.

Timing belt Infographic

libterm.com

libterm.com