A hole is an opening or hollow space in a solid object or surface, often created by drilling, digging, or natural processes. It can serve various purposes, such as ventilation, drainage, or passage. Explore the rest of the article to discover different types of holes and their practical uses.

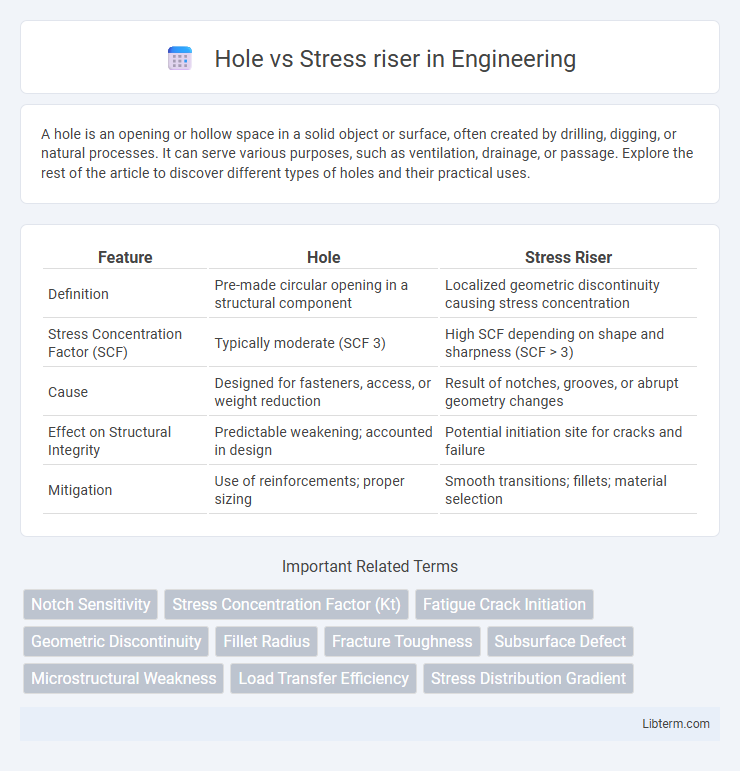

Table of Comparison

| Feature | Hole | Stress Riser |

|---|---|---|

| Definition | Pre-made circular opening in a structural component | Localized geometric discontinuity causing stress concentration |

| Stress Concentration Factor (SCF) | Typically moderate (SCF 3) | High SCF depending on shape and sharpness (SCF > 3) |

| Cause | Designed for fasteners, access, or weight reduction | Result of notches, grooves, or abrupt geometry changes |

| Effect on Structural Integrity | Predictable weakening; accounted in design | Potential initiation site for cracks and failure |

| Mitigation | Use of reinforcements; proper sizing | Smooth transitions; fillets; material selection |

Understanding Holes and Stress Risers: Key Differences

Holes act as intentional geometric discontinuities often designed for assembly or weight reduction, while stress risers are unintentional flaws or abrupt changes in geometry causing localized stress concentration. Stress risers significantly reduce structural integrity by amplifying stress around features like notches, cracks, or holes, leading to potential failure under load. Understanding the distinction between designed holes and unintended stress risers is critical for optimizing mechanical component durability and preventing fatigue-related breakdowns.

The Science Behind Stress Concentration

Stress concentration occurs when stress significantly increases around discontinuities such as holes and notches in a material, leading to localized stress risers. The presence of a hole disrupts the uniform distribution of stress, causing stress to amplify near the edges according to principles described by stress concentration factors (SCFs). Understanding the science behind stress concentration involves analyzing how geometric features influence the mechanical behavior of materials under load, which is critical for predicting failure points in structural components.

How Holes Act as Stress Risers

Holes act as stress risers by creating points of concentrated stress where the material cross-section is reduced, leading to localized increases in stress around the hole's edges. The geometry of the hole disrupts the uniform distribution of applied loads, causing stress to intensify significantly at the hole's periphery, which can initiate crack formation and propagation. Analytical methods such as linear elastic fracture mechanics quantify this effect using stress concentration factors, highlighting the critical role holes play in reducing structural integrity under mechanical loads.

Common Applications: Holes in Engineering Design

Holes in engineering design often serve as stress risers by concentrating stress in their vicinity, which is critical in components like shafts, beams, and pressure vessels where load distribution must be carefully managed. Common applications include bolt holes, keyways, and drain holes, where precise sizing and placement minimize the risk of crack initiation and fatigue failure. Advanced finite element analysis aids in optimizing hole geometry to balance functional requirements with structural integrity.

Stress Riser Mechanisms and Material Failure

Stress risers, also known as stress concentrators, are local discontinuities in a material where stress is amplified, commonly occurring around holes, notches, or sharp corners. These stress riser mechanisms cause localized increases in stress that exceed the nominal stress, often initiating cracks and accelerating material failure through fatigue or fracture. Understanding the interaction between stress risers and material properties is crucial for predicting failure modes and designing components with enhanced durability and reliability.

Factors Influencing Stress Around Holes

Stress concentration around holes is primarily influenced by hole geometry, including size, shape, and edge finish, which determine the local stress distribution and intensity. Material properties such as elasticity and ductility affect how stress is transferred and dissipated near the hole boundary. Loading conditions, including the type, magnitude, and direction of applied forces, significantly impact the stress riser effect and potential for crack initiation.

Mitigating the Impact of Stress Risers

Mitigating the impact of stress risers involves design strategies such as smoothing sharp corners, adding fillets, and using gradual transitions to distribute stress more evenly around holes or geometric discontinuities. Employing materials with high fracture toughness and incorporating surface treatments like shot peening can further enhance resistance to crack initiation and propagation at these critical points. Finite element analysis (FEA) helps identify stress concentration areas, allowing engineers to optimize structural integrity and extend the lifespan of components.

Hole Geometry: Shape, Size, and Placement Effects

Hole geometry significantly influences stress concentration, with variations in shape, size, and placement altering how stress is distributed around the hole. Circular holes generally create uniform stress risers, while elliptical or irregular shapes intensify localized stress, increasing the risk of crack initiation. Larger holes or those positioned near load-bearing edges amplify stress concentration factors, adversely affecting structural integrity and fatigue life.

Case Studies: Failures Due to Improper Hole Design

Case studies of failures due to improper hole design reveal that stress risers around holes can significantly weaken structural components, leading to catastrophic fractures. Analysis of aircraft wing failures highlights how poorly designed holes with sharp edges or insufficient edge distance became focal points for crack initiation under cyclic loading. Engineering investigations emphasize the necessity of optimized hole geometry and adequate fillet radii to minimize stress concentration factors and enhance overall material durability.

Best Practices for Managing Holes and Stress Risers in Structures

Effective management of holes and stress risers in structures involves precise design and material selection to minimize localized stress concentrations. Implementing smooth transitions, adequate hole spacing, and using reinforcement techniques such as fillets or inserts reduce the risk of crack initiation and propagation. Regular inspection and employing finite element analysis help identify potential stress risers, ensuring structural integrity and durability.

Hole Infographic

libterm.com

libterm.com