Fluid bearings use a thin layer of liquid or gas to support rotating shafts, significantly reducing friction and wear compared to traditional bearings. These bearings provide smoother operation, higher load capacity, and longer lifespan in machinery ranging from turbines to precision instruments. Explore the article to understand how fluid bearings can enhance your equipment's performance and maintenance.

Table of Comparison

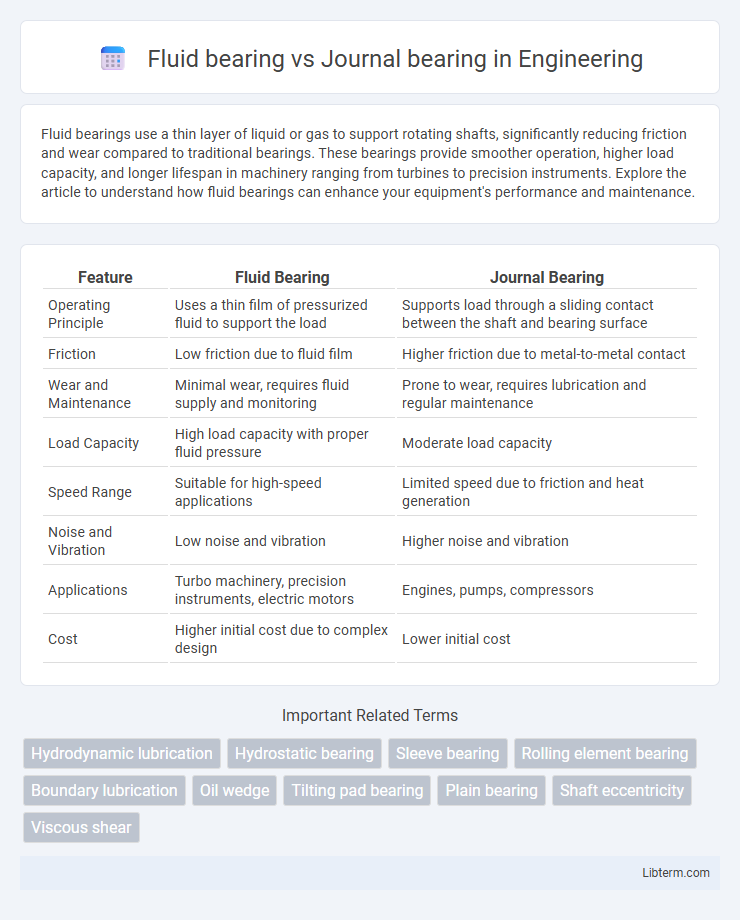

| Feature | Fluid Bearing | Journal Bearing |

|---|---|---|

| Operating Principle | Uses a thin film of pressurized fluid to support the load | Supports load through a sliding contact between the shaft and bearing surface |

| Friction | Low friction due to fluid film | Higher friction due to metal-to-metal contact |

| Wear and Maintenance | Minimal wear, requires fluid supply and monitoring | Prone to wear, requires lubrication and regular maintenance |

| Load Capacity | High load capacity with proper fluid pressure | Moderate load capacity |

| Speed Range | Suitable for high-speed applications | Limited speed due to friction and heat generation |

| Noise and Vibration | Low noise and vibration | Higher noise and vibration |

| Applications | Turbo machinery, precision instruments, electric motors | Engines, pumps, compressors |

| Cost | Higher initial cost due to complex design | Lower initial cost |

Introduction to Fluid Bearings and Journal Bearings

Fluid bearings use a thin layer of liquid or gas to support the load, minimizing direct contact and reducing friction and wear in rotating machinery. Journal bearings, a subset of fluid bearings, rely on a hydrodynamic film created by the relative motion between the shaft and bearing surface to support radial loads. Fluid bearings offer superior performance in terms of load capacity and longevity, especially in high-speed and precision applications compared to conventional journal bearings.

Basic Principles of Bearing Operation

Fluid bearings operate by maintaining a thin film of lubricant, usually oil or gas, that supports the load and minimizes direct contact between moving surfaces. Journal bearings rely on a similar hydrodynamic principle where the rotating shaft is suspended by a continuous layer of lubricant, preventing metal-to-metal contact and reducing friction. Both bearings convert relative motion into a fluid film, but fluid bearings often use externally pressurized lubrication, while journal bearings depend on the self-generated pressure from shaft rotation.

Types and Classifications of Fluid Bearings

Fluid bearings primarily include hydrostatic and hydrodynamic types, distinguished by their lubrication methods; hydrostatic bearings use an external pump to supply pressurized fluid, while hydrodynamic bearings rely on the relative motion between surfaces to generate a lubricating film. Journal bearings, a subcategory of hydrodynamic fluid bearings, support radial loads by allowing a shaft to rotate within a lubricated sleeve, classified further into full, partial, and tilting-pad journal bearings based on design and load distribution. Other classifications of fluid bearings consider factors such as load capacity, operating speed, and fluid type, including gas bearings that use compressed air or other gases for lubrication and support.

Design and Construction of Journal Bearings

Journal bearings feature a cylindrical sleeve, commonly made from materials like babbitt, bronze, or polymer composites, designed to support rotating shafts by creating a thin fluid film between the shaft and bearing surface. The design incorporates precise clearances to maintain hydrodynamic lubrication, minimizing metal-to-metal contact and reducing friction and wear. Fluid bearings, by contrast, rely solely on a pressurized liquid film without metal contact, but journal bearings balance robustness and self-aligning capabilities through their engineered construction and material selection.

Performance Comparison: Fluid vs. Journal Bearings

Fluid bearings deliver superior performance with lower friction and wear rates compared to journal bearings, ensuring smoother operation and longer service life in high-speed applications. They maintain a consistent lubricating film that minimizes metal-to-metal contact, reducing heat generation and energy losses. Journal bearings, while more robust and cost-effective, exhibit higher friction and wear due to their reliance on hydrodynamic lubrication that falters under variable loads and speeds.

Lubrication Mechanisms and Efficiency

Fluid bearings utilize a dynamic film of lubricant generated by relative motion, creating a hydrodynamic wedge that supports load with minimal friction. Journal bearings rely on a hydrodynamic oil film formed between a rotating shaft and bearing surface, but often experience higher viscous drag due to closer contacts and thinner lubrication layers. Fluid bearings typically achieve greater efficiency by maintaining a thicker, more stable lubricant film, reducing wear and energy loss compared to traditional journal bearings.

Applications and Industry Usage

Fluid bearings offer superior performance in high-speed applications such as turbines, compressors, and precision machinery due to their low friction and minimal wear characteristics. Journal bearings are extensively used in heavy machinery and automotive engines where robust load-carrying capacity and cost-effectiveness are critical. Industries including aerospace, energy, and manufacturing select fluid bearings for precision and reliability, while journal bearings dominate construction, mining, and transportation sectors because of their durability under heavy loads.

Advantages of Fluid Bearings over Journal Bearings

Fluid bearings provide superior load-carrying capacity and reduced friction compared to journal bearings, resulting in enhanced efficiency and longer operational life. They offer improved vibration damping and quieter performance due to the hydrodynamic film that separates moving parts, minimizing wear and maintenance needs. Fluid bearings also support higher rotational speeds with greater stability, making them ideal for precision machinery and high-speed applications.

Common Challenges and Maintenance Issues

Fluid bearings and journal bearings commonly face challenges such as lubricant contamination, wear due to insufficient film thickness, and thermal degradation affecting performance and lifespan. Maintenance issues often include the need for regular lubrication checks, alignment inspections, and monitoring for vibration or noise indicating bearing distress. Effective sealing and timely replacement of worn components are critical to preventing catastrophic failures and ensuring operational reliability.

Future Trends in Bearing Technology

Fluid bearings, offering reduced friction and enhanced load capacity through a thin film of lubricant, are evolving with advancements in smart sensor integration for real-time condition monitoring and predictive maintenance. Journal bearings continue to improve in material science, adopting advanced composites and nano-coatings to increase durability and thermal stability, addressing increasing demands in high-speed machinery. Future trends emphasize hybrid bearing systems combining fluid and journal technologies to optimize performance in aerospace, automotive, and industrial applications, driven by the rise of electric and autonomous vehicles.

Fluid bearing Infographic

libterm.com

libterm.com