Couple balancing enhances relationship harmony by fostering mutual understanding and shared responsibilities. Effective communication and empathy are essential tools for maintaining this equilibrium, reducing conflicts, and promoting connection. Discover practical strategies to achieve and sustain balance in your relationship by reading the rest of the article.

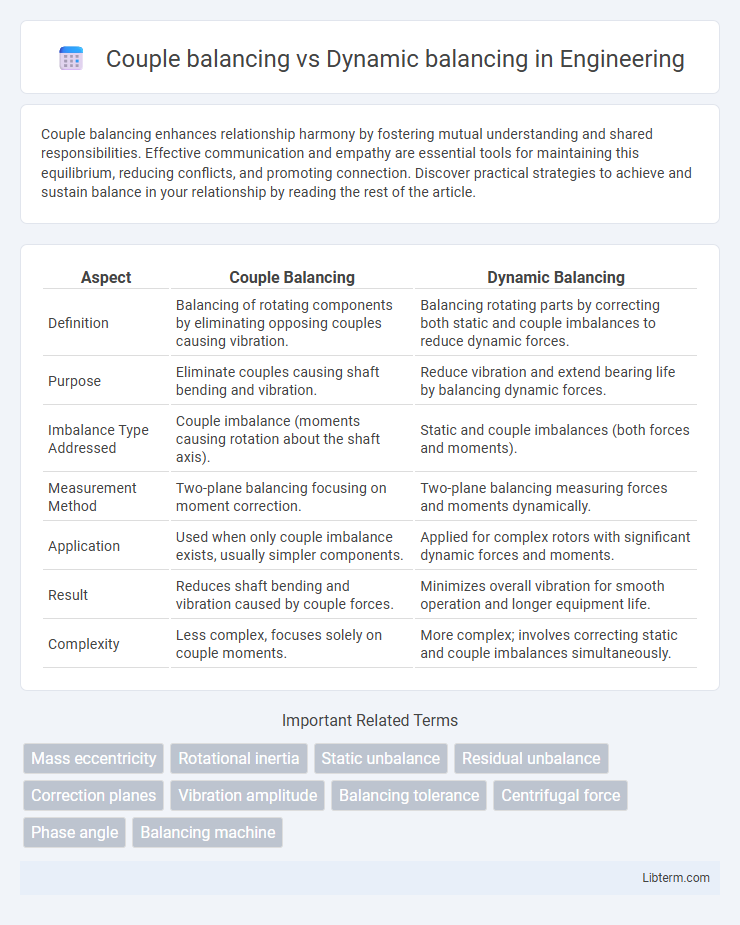

Table of Comparison

| Aspect | Couple Balancing | Dynamic Balancing |

|---|---|---|

| Definition | Balancing of rotating components by eliminating opposing couples causing vibration. | Balancing rotating parts by correcting both static and couple imbalances to reduce dynamic forces. |

| Purpose | Eliminate couples causing shaft bending and vibration. | Reduce vibration and extend bearing life by balancing dynamic forces. |

| Imbalance Type Addressed | Couple imbalance (moments causing rotation about the shaft axis). | Static and couple imbalances (both forces and moments). |

| Measurement Method | Two-plane balancing focusing on moment correction. | Two-plane balancing measuring forces and moments dynamically. |

| Application | Used when only couple imbalance exists, usually simpler components. | Applied for complex rotors with significant dynamic forces and moments. |

| Result | Reduces shaft bending and vibration caused by couple forces. | Minimizes overall vibration for smooth operation and longer equipment life. |

| Complexity | Less complex, focuses solely on couple moments. | More complex; involves correcting static and couple imbalances simultaneously. |

Introduction to Balancing Techniques

Couple balancing addresses unbalanced forces caused by pairs of equal and opposite forces acting at a distance, primarily correcting moments in rotating machinery to reduce vibrations. Dynamic balancing involves correcting both static and couple unbalances by ensuring the mass distribution allows smooth rotation without generating excessive forces or moments. These balancing techniques are crucial in optimizing the performance and longevity of rotors, turbines, and other spinning components by minimizing stress and wear.

Defining Couple Balancing

Couple balancing involves counteracting a pair of equal and opposite forces acting on a rotating body to reduce unbalanced moments and vibrations. It specifically targets the elimination of couples, ensuring the rotor's axis remains stable during rotation. Dynamic balancing, by contrast, addresses mass distribution along multiple planes to correct both static and couple imbalances for smoother operation.

Understanding Dynamic Balancing

Dynamic balancing ensures that rotating components operate smoothly by correcting both the magnitude and phase of unbalanced forces, reducing vibration and wear. Unlike couple balancing, which only addresses forces in one plane, dynamic balancing involves multiple planes to prevent oscillations and improve machine longevity. This process relies on precise measurement tools and balancing machines to detect out-of-balance conditions across the rotational axis.

Key Differences: Couple vs Dynamic Balancing

Couple balancing involves correcting unbalanced forces that create a rotational couple, typically in rigid rotors without significant axial movement, by applying counteracting moments to eliminate vibration. Dynamic balancing addresses both static and couple unbalances by adjusting mass distribution across multiple planes to reduce unbalanced centrifugal forces and moments in rotors that operate at high speeds and have flexible shafts. The key difference lies in couple balancing targeting moment imbalances only, while dynamic balancing corrects moments and force imbalances affecting rotor stability and operational precision.

Applications of Couple Balancing

Couple balancing is primarily used in applications where rotating components experience unbalanced moments due to offset masses, such as automotive crankshafts and helicopter rotors, ensuring smoother operation and reduced vibrations. This method targets balancing moments rather than just forces, making it essential for high-speed machinery requiring precision motion control. Compared to dynamic balancing, which addresses both unbalance forces and moments, couple balancing focuses on neutralizing torque-producing couples to enhance mechanical stability and longevity in specialized rotating systems.

Applications of Dynamic Balancing

Dynamic balancing is essential in high-speed rotating machinery such as turbines, automotive crankshafts, and aerospace components to minimize vibration and enhance operational efficiency. This method corrects unbalanced forces and moments by adjusting mass distribution along multiple planes, ensuring smoother rotation and reduced bearing wear. Its applications extend to precision instruments, electric motors, and industrial fans, where dynamic balance is critical for safety, longevity, and performance optimization.

Advantages of Couple Balancing

Couple balancing offers precise correction of unbalanced forces in rotating machinery by counteracting moments with equal and opposite couples, reducing vibrations and extending equipment lifespan. It provides enhanced stability during operation compared to dynamic balancing, which primarily addresses unbalanced mass forces but may not fully compensate for moment-induced vibrations. This method improves operational safety and maintenance intervals by minimizing stress on bearings and structural components.

Benefits of Dynamic Balancing

Dynamic balancing offers superior vibration reduction by addressing imbalances in both the rotating mass and its distribution along the axis, enhancing machine performance and longevity. Unlike couple balancing, which only compensates for couples causing rotational forces, dynamic balancing corrects both static and couple imbalances, ensuring smoother operation at higher speeds. This leads to reduced bearing wear, lower maintenance costs, and improved overall efficiency in rotating equipment.

Common Challenges in Balancing Methods

Couple balancing often faces challenges such as accurately identifying unbalanced force pairs and managing asymmetrical mass distributions, which can lead to residual vibrations in rotating machinery. Dynamic balancing struggles primarily with detecting and correcting multi-plane imbalances, requiring precise instrumentation and complex computations to achieve optimal performance. Both methods demand meticulous measurement and adjustment processes to minimize vibration, enhance equipment lifespan, and ensure operational stability.

Choosing the Right Balancing Technique

Choosing the right balancing technique depends on the rotor's design and operational speed; couple balancing is ideal for rotors with two planes of imbalance, commonly used in medium-speed applications where correcting residual couple moments is critical. Dynamic balancing addresses unbalance in multiple planes by simultaneously correcting mass distribution, suitable for high-speed rotors requiring precise vibration reduction. Selecting between couple and dynamic balancing ensures optimal rotor longevity and vibration control based on specific mechanical and performance requirements.

Couple balancing Infographic

libterm.com

libterm.com