Boundary lubrication occurs when a thin layer of lubricant molecules adheres to contact surfaces, reducing friction and wear under extreme pressure or low-speed conditions. This mechanism is crucial in machinery where full fluid film lubrication cannot be maintained, providing essential protection by preventing direct metal-to-metal contact. Discover how understanding boundary lubrication can enhance the performance and longevity of your mechanical components by reading the rest of this article.

Table of Comparison

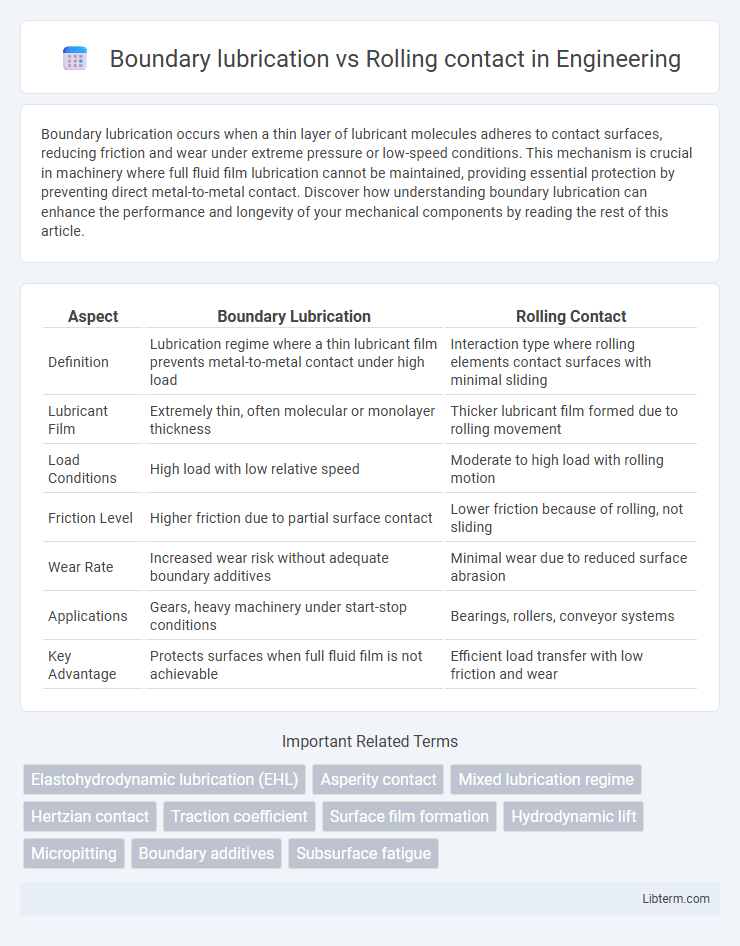

| Aspect | Boundary Lubrication | Rolling Contact |

|---|---|---|

| Definition | Lubrication regime where a thin lubricant film prevents metal-to-metal contact under high load | Interaction type where rolling elements contact surfaces with minimal sliding |

| Lubricant Film | Extremely thin, often molecular or monolayer thickness | Thicker lubricant film formed due to rolling movement |

| Load Conditions | High load with low relative speed | Moderate to high load with rolling motion |

| Friction Level | Higher friction due to partial surface contact | Lower friction because of rolling, not sliding |

| Wear Rate | Increased wear risk without adequate boundary additives | Minimal wear due to reduced surface abrasion |

| Applications | Gears, heavy machinery under start-stop conditions | Bearings, rollers, conveyor systems |

| Key Advantage | Protects surfaces when full fluid film is not achievable | Efficient load transfer with low friction and wear |

Introduction to Boundary Lubrication and Rolling Contact

Boundary lubrication occurs when a thin film of lubricant separates contacting surfaces under high pressure and low speed, preventing direct metal-to-metal contact and reducing wear. Rolling contact involves the motion of one surface rolling over another, typically found in bearings and gears, where lubricant film thickness is critical to avoid surface fatigue. Understanding the differences in lubrication regimes and contact mechanics is essential for optimizing machine component performance and longevity.

Defining Boundary Lubrication

Boundary lubrication occurs when a thin lubricant film separates two surfaces under high load, preventing direct metal-to-metal contact by forming a protective molecular layer. This regime is crucial in conditions where the lubricant film is too thin to fully separate surfaces, such as during start-up or slow movement. Rolling contact, in contrast, involves the continuous rotation of components like bearings, where hydrodynamic lubrication typically maintains a thicker fluid film to minimize wear and friction.

Understanding Rolling Contact Mechanisms

Rolling contact involves the interaction of two surfaces where one rolls over the other, minimizing friction and wear by maintaining a lubricating film that prevents direct metal-to-metal contact. Boundary lubrication occurs when this lubricating film is insufficient or breaks down, causing surfaces to interact with higher friction and increased wear due to asperity contact. Understanding rolling contact mechanisms requires analyzing the lubricant film thickness, contact pressure, and surface roughness to optimize lubrication regimes and extend component life in applications like bearings and gears.

Key Differences Between Boundary Lubrication and Rolling Contact

Boundary lubrication occurs when a thin lubricant film separates surfaces under high load and low speed, preventing direct metal-to-metal contact through adsorbed lubricant molecules. Rolling contact involves the interaction of rolling elements, such as balls or rollers, where lubrication primarily reduces friction and wear between rolling surfaces under high-speed and moderate load conditions. Key differences include the lubrication regime, where boundary lubrication acts under severe conditions with minimal fluid film, while rolling contact relies on hydrodynamic or elastohydrodynamic lubrication maintaining a thicker lubricant film.

Material Selection in Boundary vs. Rolling Contact

Material selection in boundary lubrication prioritizes metals and polymers with high wear resistance and low friction coefficients to maintain a protective film under high load and low speed conditions. Rolling contact demands materials such as hardened steel or ceramics with excellent fatigue strength and surface hardness to withstand repetitive cyclic stresses. Optimizing material properties like hardness, toughness, and surface finish is critical for enhancing the durability and performance of components under both lubrication regimes.

Lubricant Types and Application Methods

Boundary lubrication primarily utilizes high-viscosity oils and grease formulations enriched with extreme pressure (EP) additives to prevent metal-to-metal contact under low-speed or high-load conditions. Lubricants for rolling contact applications often include low-viscosity oils or synthetic fluids optimized for minimizing friction and heat generation between rolling elements and raceways. Application methods differ, with boundary lubrication relying on grease packing or oil drip systems for localized protection, whereas rolling contact bearings typically use circulating oil systems or oil mist lubrication to ensure continuous film formation and effective cooling.

Friction and Wear Characteristics

Boundary lubrication significantly reduces friction and wear by maintaining a thin lubricant film that separates metal surfaces, preventing direct asperity contact. In rolling contact, such as in bearings and gears, elastohydrodynamic lubrication forms a thicker lubricant film under high pressure, minimizing friction and wear more effectively than boundary lubrication. The primary difference lies in the lubricant film thickness and pressure conditions, with rolling contact generally exhibiting lower friction coefficients and enhanced wear resistance due to higher lubricant film formation.

Real-world Applications and Use Cases

Boundary lubrication is critical in automotive engines and gear systems where metal surfaces experience high loads and low speeds, preventing direct metal-to-metal contact and reducing wear. Rolling contact lubrication is essential in ball bearings and railway wheels, ensuring smooth motion by maintaining a fluid film that separates rolling elements under high-speed conditions. Both lubrication types optimize machine efficiency and longevity, with boundary lubrication excelling in start-stop conditions and rolling contact lubrication dominating continuous motion applications.

Advantages and Limitations of Each Mechanism

Boundary lubrication excels in preventing direct surface contact under high load conditions by forming a protective molecular film, reducing wear and friction in harsh environments. Rolling contact lubrication minimizes friction and wear through a continuous lubricant film supporting rolling elements, offering high efficiency in bearings and gears but requiring precise alignment and contamination control. While boundary lubrication is effective in extreme pressures and speeds, it can suffer from film breakdown, whereas rolling contact lubrication depends heavily on maintaining lubricant viscosity and cleanliness for optimal performance.

Conclusion: Choosing the Optimal Lubrication Method

Selecting the optimal lubrication method depends on operational conditions; boundary lubrication is ideal for low-speed, high-load environments where direct surface contact occurs, while rolling contact lubrication excels in high-speed applications with rolling elements like bearings. Proper lubrication reduces wear, minimizes friction, and extends machinery lifespan, directly impacting reliability and maintenance costs. Evaluating factors such as load, speed, temperature, and material compatibility ensures the most effective lubrication strategy is implemented.

Boundary lubrication Infographic

libterm.com

libterm.com